In the present times, architects and builders are focused on building energy efficient constructions. POLYWELL thermal break strips eliminates the difficulties of heat transfer and thereby promotes the heat energy efficiency in buildings. The strip, which is made from PA66 GF25 plastic, is inserted between interior and exterior faces in order to prevent heat flux from one face to the other, thus reducing energy wastage. The use of POLYWELL thermal break strips enables the construction industry professionals to participate in the making of green and energy efficient structures.

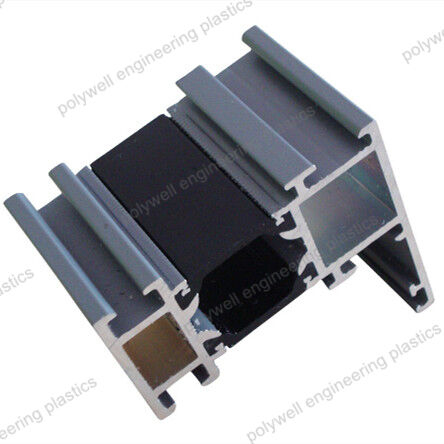

The passages have been identified when heat flows through a conducting substance like metals in frame work for energy loss and in this case thermal bridging takes place. This is especially evident in constructions where aluminum is used in the windows and doors. Aluminum has many benefits of which strength and stability are the most important but aluminum also has poor thermal conductivity properties. POLYWELL thermal break strips are one of the products specifically developed to solve this problem. They are fixed in aluminum frames, and allow much lower heat penetration, improving thermal conditions inside the building and saving energy costs.

It is not only about energy savings for which the POLYWELL thermal break strips provide the thermal resistance as well. Warm air in the building can lead to condensation on windows and doors which in turn can lead to moisture damage like mould and rotting of structures. POLYWELL thermal break strips manage to reduce condensation accumulation by controlling surface temperatures and reducing thermal bridges. This level of moisture management is critical for ensuring the building structure remains strong and the indoor air is free of contaminants.

Moreover, POLYWELL thermal break strips also provide some level of sound insulation within a building. Noise from traffic and other activities can be a nuisance when living or working in high-density urban areas. Introducing thermal break strips enables the use of more acoustic insulation as well which helps minimize noise coming through the outside environments. This feature is particularly advantageous for houses as a quieter atmosphere is sought for such properties.

Thermal break strips have been one of POLYWELL thermal break strips’ greatest assets as they are compatible with many types of framing systems. Be it in aluminium or wood or PVC, builders can fit these strips into their design for any material. Such versatility encourages architects and builders to come up with elegant and functional designs in the as well as effective energy performance. The ability to use POLYWELL thermal break strips across different materials enhances their appeal across many construction projects.

The use of thermal break strips also conforms to the increasing market demand of incorporating sustainable construction techniques. Currently, construction fit outs and building designs need to target energy efficiency as a key building purpose. This comes from the fact that there is an increase in pollution and may be caused by buildings. POLYWELL thermal break strips assist to realize these objectives by eliminating the requirement of heating and cooling therapies and thus lowering energy bills and carbon footprints.

Apart from the obvious benefits that POLYWELL thermal break strips offer such as energy savings, ease of installation is yet another feature that gives them an edge over the rest. As the thermal break strips are meant to be applied on existing construction systems, they can be installed with speed and efficiency. This feature not only saves time during the construction process but also helps the Comprehensive efficiency of the project.

Durability or lifetime goes hand in hand with the effectiveness of POLYWELL thermal break strips and their usage in division walls. Instead of fogging the strips are designed to resist abrasion from UV light, water as well as high and low temperatures. Such durability guarantees that the said materials would be subservient for a considerably longer period of time delivering more value to the building owners and occupants’ nthawi.