Heat and Sound Insulation Nylon Heating Barrier Profile Thermal Break Polyamide Strip for Aluminum System Window

Nylon Chain Guide Profile Rail Guide Runway Guide PA66 Profile

- Overview

- Recommended Products

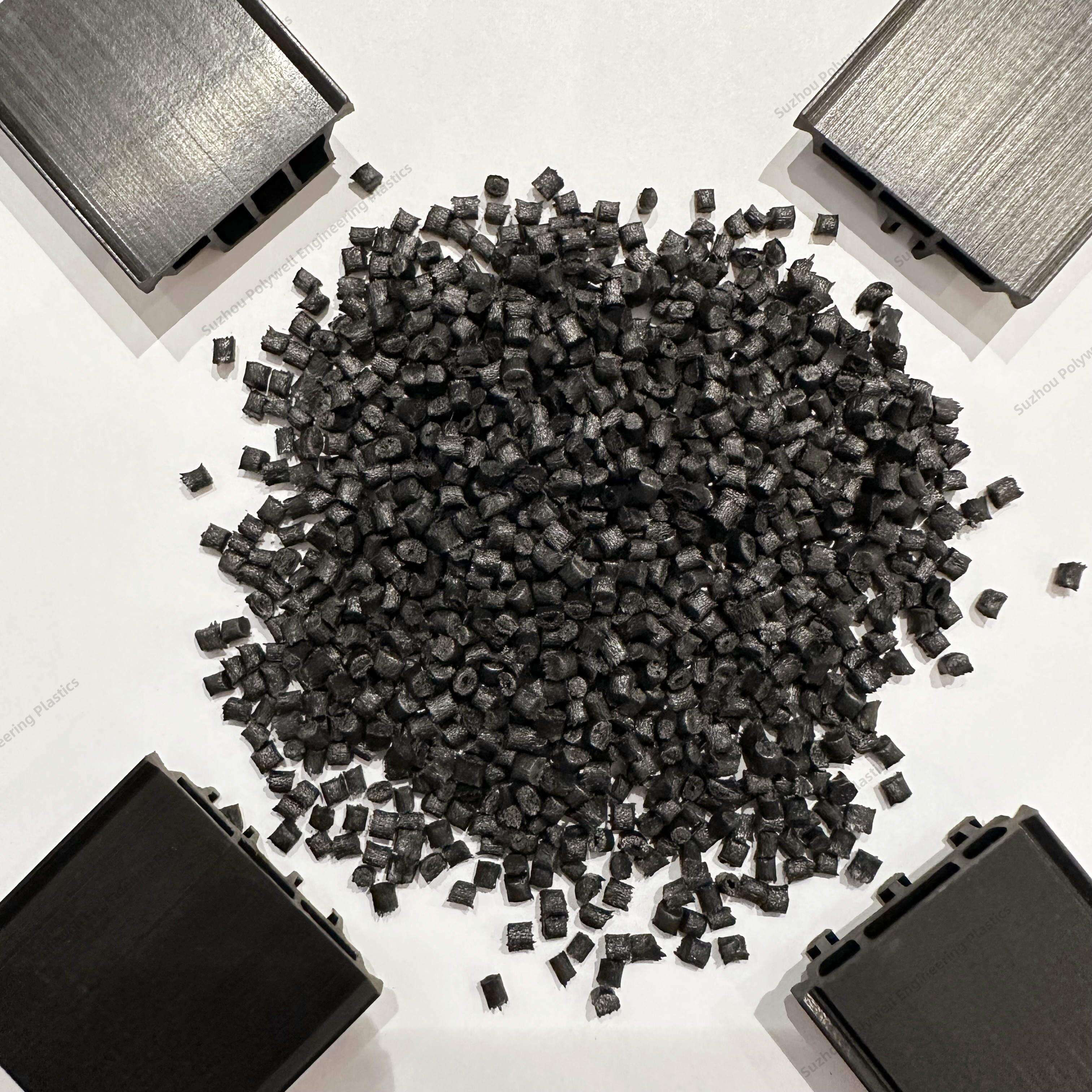

- Pre-extruded profiles made from polyamide with 25 percent glass-fiber

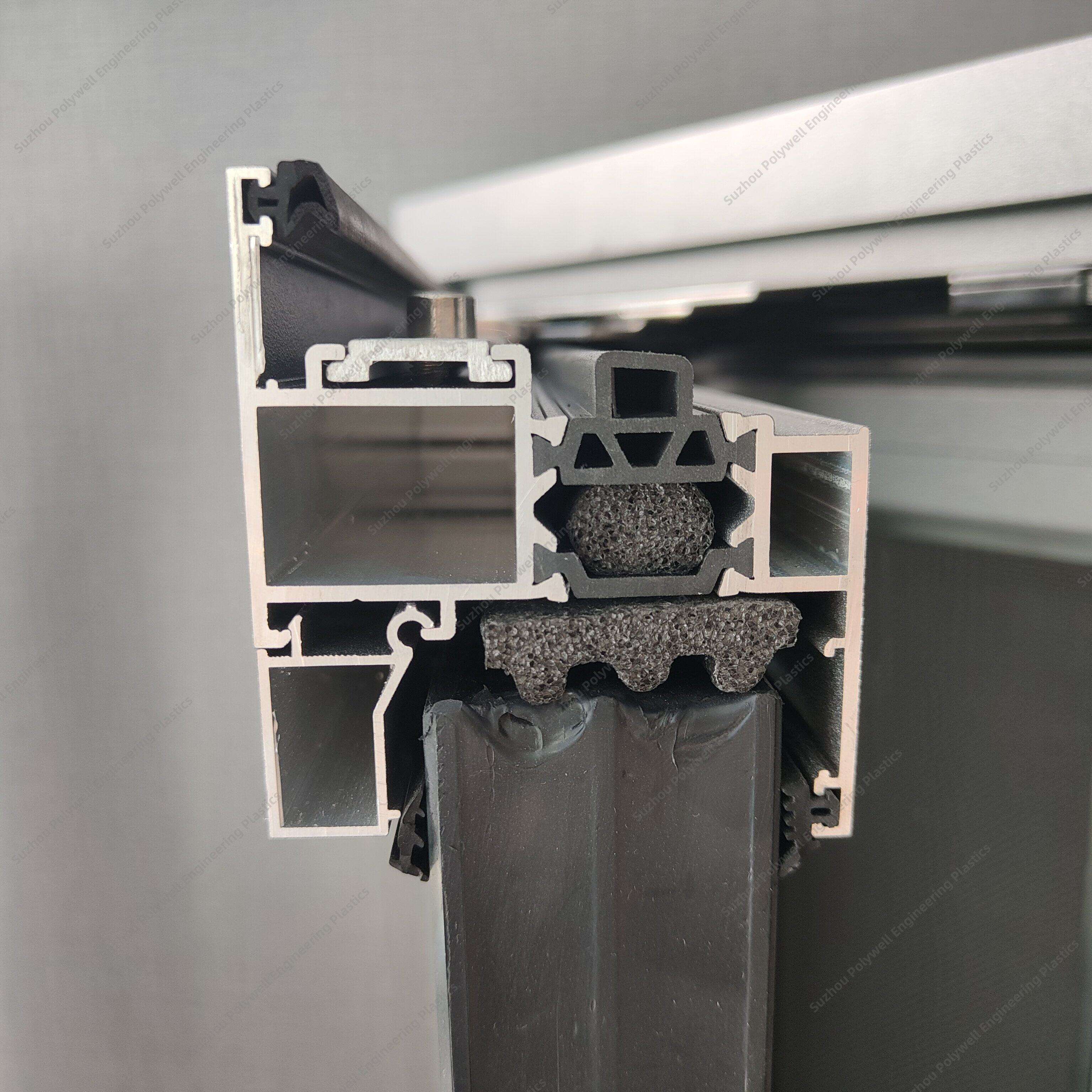

- Locked in place in ‘pockets’ extruded into two separate (inner and outer) aluminum extrusions

- Enables finished assemblies with different finishes and colors on each surface

- Aluminum extrusion pockets need to be ‘knurled’ prior to insertion of the polyamide profiles-and ‘rolled’ to create a structurally-secure finished assembly

- The polyamide profiles can be supplied with ‘sealing-wire’ which give a reliable seal and enhanced shear strength when activated by heat e.g.-powder coating

- The aluminum extrusions can be finished either before or after installation of the polyamide strips

What is Polyamide Thermal Barrier Strips?

A thermal break is a material with low thermal conductivity, placed in an assembly, to reduce or prevent the flow of thermal energy between the inside and outside of a building.

Polyamide is a plastic that insulates more than 500 times better than aluminum, so thermal break profiles have a much lower Uf value – and transmit much less heat or cold. As a result, a building stays warmer in winter while keeping the heat outside more easily in summer.

Can polyamide strips thermally break aluminum extrusion assemblies?

Yes.

Structural insulating polyamide strips have been utilized for thermally breaking aluminum extrusion assemblies for over 30 years and have been in use in north america for over a decade. Polyamide strips are available with many configurations to meet different performance specifications. Creating a thermal break utilizing a polyamide strip system entails a 3 step process.

1. Profile knurling

2. Strip insertion

3. Crimping

Why use polyamide strip as thermal barrier function?

1. Because polyamide strip including Polyamide and glass fiber, Its Strength can reach requirement for aluminum profile window, door, curtain and walls.

2. Conductivity of polyamide strip is very low, prohibit hot air or cold air transferred from outside to inside, energy saving product.

What are the different types of polyamides?

Polyamide (PA) Polyamides are among the most important and proven technical thermoplastics, known for their heat resistance, stiffness and high mechanical stability Polyamides can be classified into different types, with PA 6, PA 6.6 and PA 12 most established on the market.

Our polyamide strips are made of PA6.6 reinforced by 25% fiberglass.

The Function of Thermal Break Strips in Window

Broken bridge heat-insulated aluminum alloy doors and windows is to divide the original whole-body aluminum alloy profile into two on the basis of traditional aluminum alloy doors and windows. The overall heat-insulating profile enables the heat-insulating strip and the aluminum alloy to jointly bear the load caused by the glass's own weight, wind pressure and temperature stress. Therefore, the use nature of the heat insulation strip determines that it must have high strength and excellent stability at the same time, otherwise it will easily cause doors, windows and curtain walls to break and fall off, causing major quality and safety hazards.

The word "bridge" in the name "broken bridge aluminum" means "hot and cold bridge" in material science, and the word "broken" stands for action words, which means "cut off the hot and cold bridge". Specifically speaking, aluminum alloy is a metal medium with strong thermal conductivity. When it collides with the temperature outside the house by a large difference, the aluminum alloy becomes a "bridge" for heat transfer. Using this type of material to make doors and windows, it will have Poor insulation too. However, the broken bridge aluminum is to disconnect the aluminum alloy from the middle, and the thermal conductivity of the plastic will be weaker than that of the metal. The disconnected aluminum alloy is connected together with hard plastic, so that the heat will not easily flow to the whole. material, so the heat insulation will become better, which is the origin of the name "broken bridge aluminum (alloy)".

What is a Thermal Barrier?

Thermal barriers are made from resins that create a “thermal break” between the inner and outer surfaces of aluminum fenestration.

Thermal barriers reduce heat loss or heat gain through the aluminum.

Thermal barriers improve the U-value characteristics of finished systems.

Thermal barriers are about energy conservation, U-values and government codes.

70 percent of aluminum fenestration systems produced in North America contain a thermal break.

Primarily used in colder climates to reduce heat loss.

Increasing use of thermal barriers to reduce heat gain and also reduce heat loss.

Developers, architects and designers are demanding better performance in terms of power usage.

Stricter government regulations to reduce power usage in buildings to combat environmental concerns.

Aluminum, if it is to retain its market superiority in terms of its structural integrity, will have to achieve better performance in terms of U-values.

The use of thermal barriers will assist manufacturers to achieve improved LEED performance.

What is the best thermal break?

As an energy-saving, polyamide thermal break profile is the best thermal break material for aluminum profiles connections. Boasting high compressive strength, polyamide thermal break profile is a premier thermal bridging solution that won't compromise a structure's integrity.

Features:

1. The working temperature of the thermal insulation strip is 200°C. This enables coating process after assembly of composite profiles.

2. High mechanical strength, able to connect with metal hardware fittings when bearing draw and shear stress.

3. Excellent product tolerance of less than 0.1mm, ensuring air and water tightness and overall composite profile dimensions.

4. High corrosion-resistance, weather-resistance, heat-resistance, alkali-resistance and long life of usage.

5. The thermal expansion coefficient of PA66GF25 is similar to aluminum thus ensures that product does not affect the integrity of the thermally insulated aluminum profiles.

6. Precisely dimension ensures the lifespan of aluminum extrusion tools, no danger of bending cracks during rolling, very good knurling effect at the hammer head and easy to assemble.

Application and Advantages

Aluminium window has the disadvantage of limited thermal insulation. Its Uf value, which indicates the amount of heat that passes through a window profile, is simply too high. If your windows have standard aluminium profiles, your home may develop condensation, or even mould. Besides the resulting high repair costs, household mould also aggravates respiratory problems such as asthma.

But that disadvantage has now been completely eliminated if you install polyamide strips in aluminum windows. In fact, thanks to the development of a new invention known as thermal break profiles, aluminium is at least as good as its competitors. In these profiles, produced with specialized machines, a polyamide strip is placed between the inner and outer sections of the profile.

Polyamide is a plastic that insulates more than 500 times better than aluminium, so thermal break profiles have a much lower Uf value - and transmit much less heat or cold. As a result, your home stays warmer in winter, while keeping the heat outside more easily in summer.

Application of polyamide strip:

1. Used for thermal break aluminum window, door, curtain and walls.

2. Many customer use thermal break aluminum profile to do big air conditioner to keep heat of cold air, then make use of energy saving.

Characteristic of polyamide strips

Polyamide thermal breaks are extruded in dry state but they absorb moisture from the environment after the production as time passes. Moisture level depend the following conditions:

- Ambient temperature

- Ambient humidity

- Storage period

During the summer time, when the temperature and humidity in storage area are higher than usual, the insulating profiles absorb more moisture than in the remaining seasons, even stored properly.

What is the Suitable Width for Thermal Break Strips in Windows?

Generally speaking, the wider the heat insulation strip, the better. Under the premise of no damage to the product and the stability and quality of the heat insulation strip, the wider the aluminum insulation strip, the better, because the wider the heat insulation strip, the less heat transfer. The slower the window is, the better the insulation performance of the window is, and the more energy-saving it is, but the insulation strip must use PA66GF25 nylon strip.

On the contrary, if there is no quality assurance of aluminum material, poor or damaged heat insulation strips, and the toughness of the product is not up to standard, it is recommended not to choose windows with too wide heat insulation strips, because the overall airtight system is a whole system, everything has a standard, and the one that fits the standard is the best. If the heat insulation strip is narrow, the heat insulation will be worse. If the heat insulation strip is wide, it will affect the doors and windows. Other materials will be less. The load-bearing strength of the doors and windows will be reduced.

Take 70 broken bridge aluminum doors and windows as an example: the standard width of the window insulation strip is between 2 cm and 2.5 cm, and it should not be too wide or too narrow. if it is 80 series or 90 series broken bridge aluminum doors and windows, wider insulation strips can be used. For heat strips, it is recommended that if the heat insulation strip exceeds 4 cm, it is better to choose imported brand heat insulation strips or brand heat insulation strips produced by domestic large-scale heat insulation strip factories.

When the width of the heat insulation strip reaches more than 40mm, the stability of the system will become worse, and with the increase of the cavity between the heat insulation strips, the loss of heat due to the convection effect will become more and more obvious, so the wider the heat insulation strip, The material composition and design of the heat insulation strip are obviously different from the conventional heat insulation strips. The wider heat insulation strips should use mesh heat insulation strips or spacer cavities in the middle, which greatly improves the stability and heat insulation and sound insulation performance of the heat insulation strips.

PA strips storage and handling:

Because PA66 is a hydrophilic substance, it will absorb the surrounding water. The rate and amount of water absorption depend on the ambient temperature, ambient humidity and storage period.

The relative humidity is higher in summer than in other short-term storage seasons. High moisture content (more than 2%) will affect the quality of wear-resistant strips.

When the insulation single bundle is removed from the shelf, it may be deformed. If it is not straightened in time, it will cause permanent deformation.

Therefore, it is recommended to keep it horizontal in a ventilated and dry environment, pay attention to waterproof, stay away from heat source, avoid stress and minimize bending.

If you have any specific questions, please contact us and we are happy to provide you with relevant services.

Package of polyamide thermal break strips

Conventional straight package: 6m per piece. Cutting length can also be customized based on customer’s requirements.

Roll package: 300-500 meters per roll, limited to type I and type C.

According to the specific requirements of customers, large-scale production, packaging and computer laser code printing can be carried out.

Our service about test

1.Size precision inspection insulation, according to the national standard GB/T23615.1-2017, the size precision of detection for customers of heat insulation strip.

2.Detection and analysis of insulation of internal structure, according to the national standard GB/T23615.1-2017. analyze the internal structure of insulation detection for customers.

3.Insulation density test, according to the national standard GB/T23615.1-2017, the application of electronic weighing instrument for detecting insulation density.

4.According to the national standard GB/T23615.1-2017, the insulation room temperature transverse tensile characteristic value, non-notched impact strength, high temperature and transverse tensile characteristic value of the test.

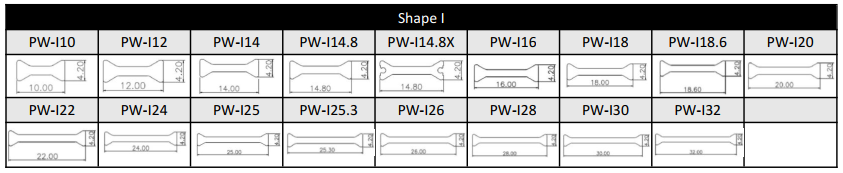

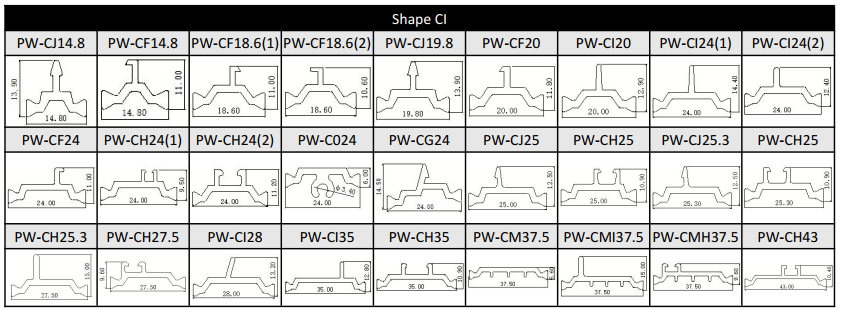

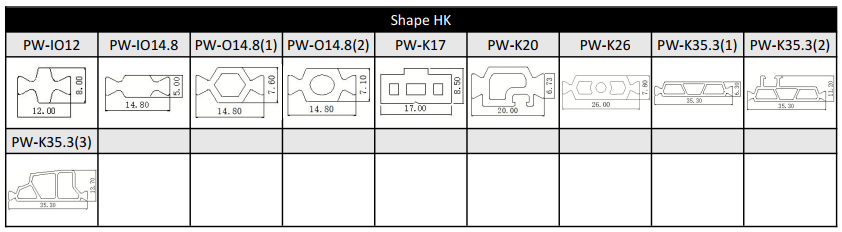

Different shapes:

I-type thermal break strip is a common insulation material for doors and windows, with a shape similar to the uppercase English letter "I". It is the first generation and easiest shape of polyamide strips.

Compared to other types of thermal break strips, the advantage of I-type strips is that their longer length can better adapt to the width of doors and windows, improving the thermal break effect.

In addition, type I insulation strips can also adapt to different door and window sizes and specifications through their own shape and structure, with high flexibility and adaptability.

For the I-type strips, we can provide the following size or customize according to customer’s drawing.

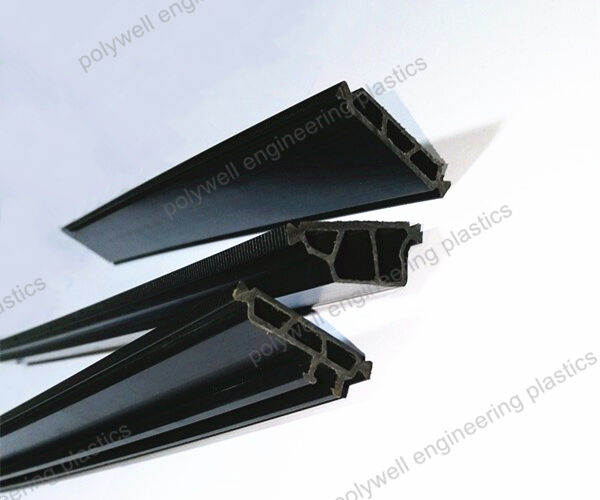

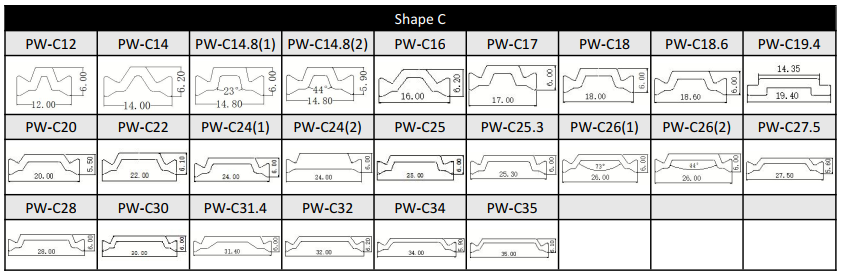

The C-type design provides a longer heat conduction path, resulting in better heat insulation performance than I-type strip, while also having better longitudinal load-bearing capacity. Besides, the C-type PA strip is also a necessary condition for the stepped drainage of thermal broken bridge aluminum.

For the C-type strip, we can provide the following size or customize according to customer's drawing.

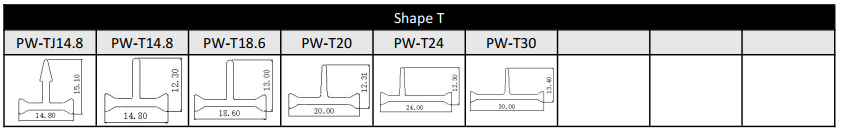

The design of T-type thermal break strips usually includes a horizontal section and a vertical section, forming a "T" - shaped structure.

This design adds a small section under the thermal break strip, allowing the sealing strip to overlap with the thermal break strips, thereby improving the overall insulation performance.

For the T-type strip, we can provide the following size or customize according to customer's drawing.

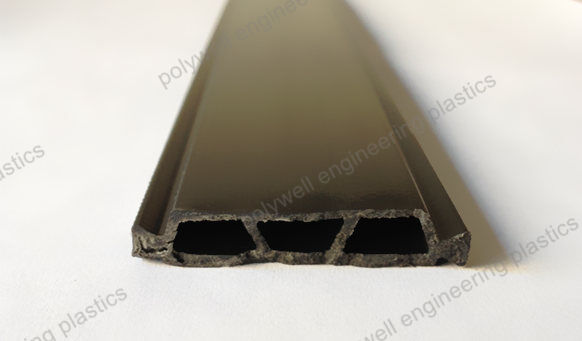

Hollow thermal break strip, also known as multi-cavity insulation strip, can reduce heat transfer by changing the air flow path, thereby achieving insulation effect and further improving insulation performance.

Hollow thermal break strip are currently the mainstream products in the market and can support large width sizes. Many thermal break strips with a diameter of 35mm or more on the market are made into multi-cavity shapes, and their longitudinal load-bearing capacity is very high.

For the hollow type strip, we can provide the following size or customize according to customer's drawing.

Product Performance

Item |

Unit |

GB/T 23615.1-2009 |

PW-Technical specification |

Density |

g/cm3 |

1.3±0.05 |

1.28-1.35 |

Linear expansion coefficient |

K-1 |

(2.3-3.5)×10-5 |

(2.3-3.5)×10-5 |

Vicat softening temperature |

ºC |

≥230 |

≥233 |

Melting point |

ºC |

≥240 |

≥240 |

Testing for tensile cracks |

- |

No cracks |

No cracks |

Shore hardness |

- |

80±5 |

77-85 |

Impact strength(Unnotched) |

KJ/m2 |

≥35 |

≥38 |

Tensile strength(longitudinal) |

MPa |

≥80a |

≥82a |

Elasticity modulus |

MPa |

≥4500 |

≥4550 |

Elongation at break |

% |

≥2.5 |

≥2.6 |

Tensile strength(transverse) |

MPa |

≥70a |

≥70a |

High temperature tensile strength(transverse) |

MPa |

≥45a |

≥47a |

Low temperature tensile strength(transverse) |

MPa |

≥80a |

≥81a |

Water resistance tensile strength(transverse) |

MPa |

≥35a |

≥35a |

Aging resistance tensile strength(transverse) |

MPa |

≥50a |

≥50a |

1. Sample water content less than 0.2% by weight.

2. Norm laboratory condition:(23±2)ºC and (50±10)% relative humidity.

3. The specifications marked with "a" only applies to I-shape strip otherwise, the specifications concluded between supplier and buyer through consultation, shall be written in contract or purchase order.

EN

EN