Nylon Fire Resistant Heat Breaking Profiles PA66 Thermal Break Strip for Aluminum Window and Doors

Nylon Chain Guide Profile Rail Guide Runway Guide PA66 Profile

- Overview

- Recommended Products

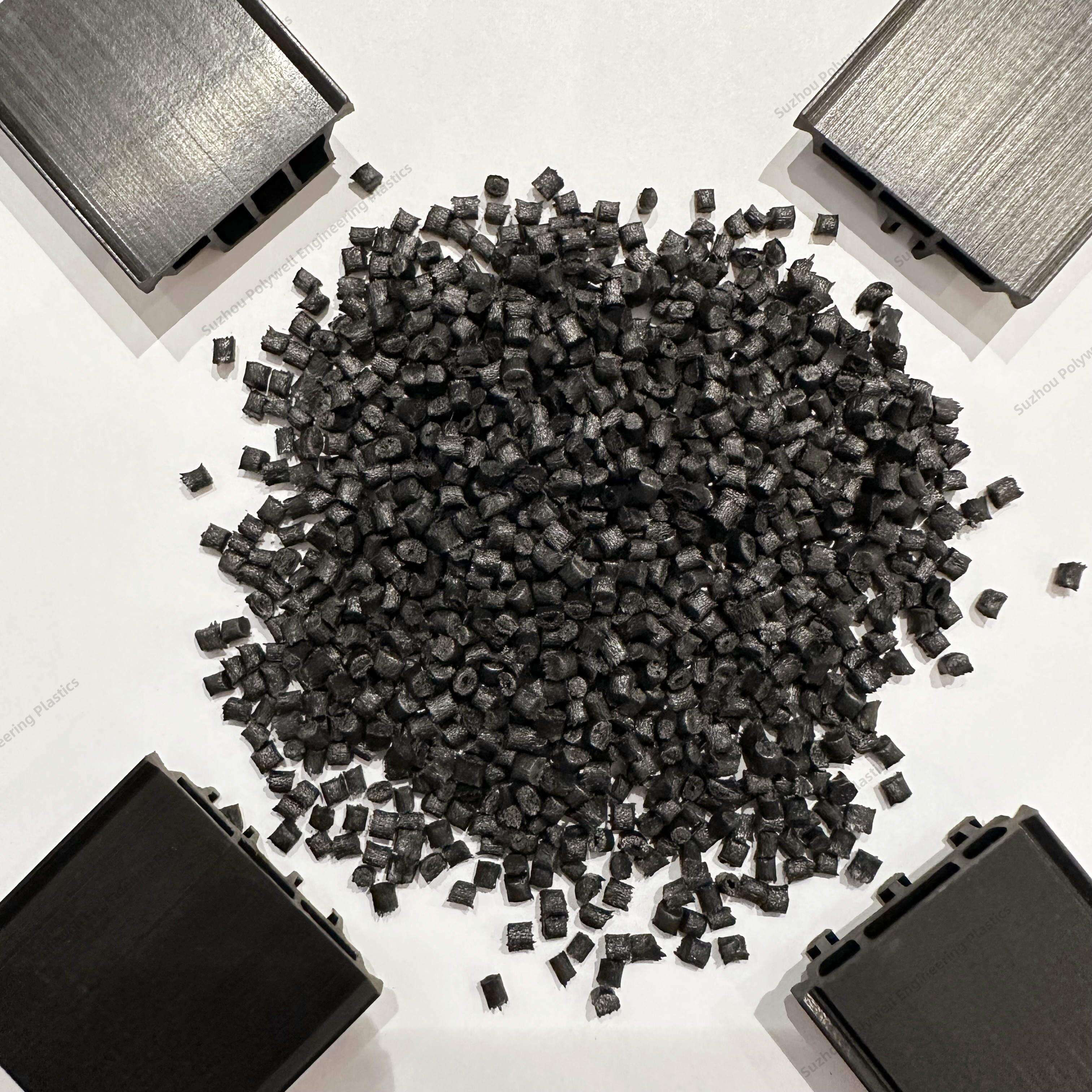

What is a polyamide strip?

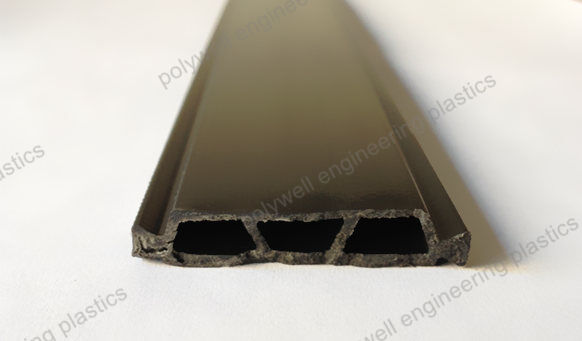

The polyamide strip is a moldable composite material. Its fibers are oriented in all three dimensions to ensure appropriate strength. As such, manufacturers can use these strips across all types of fenestration, including oversized and impact-resistant systems. Therefore, polyamide thermal barriers are the best for thermal break windows.

Why use a polyamide strip as a thermal barrier function?

1. Because the polyamide strip includes polyamide and glass fiber, its strength can reach the requirement for aluminum profile windows, doors, and curtain walls.

2. Conductivity of polyamide strip is very low, prohibit hot air or cold air from being transferred from outside to inside, making it an energy-saving product

Features:

1. The working temperature of the thermal insulation strip is 200°C. This enables coating process after assembly of composite profiles;

2. High mechanical strength, able to connect with metal hardware fittings when bearing draw and shear stress;

3. Excellent product tolerance of less than 0.1mm, ensuring air and water tightness and overall composite profile dimensions;

4. High corrosion-resistance, weather-resistance, heat-resistance, alkali resistance, and long life of usage;

5. The thermal expansion coefficient of PA66GF25 is similar to aluminum, thus ensures that product does not affect the integrity of the thermally insulated aluminum profiles;

6. Precise dimension ensures the lifespan of aluminum extrusion tools, no danger of bending cracks during rolling, a very good knurling effect at the hammerhead, and easy assembly.

Application and Advantages

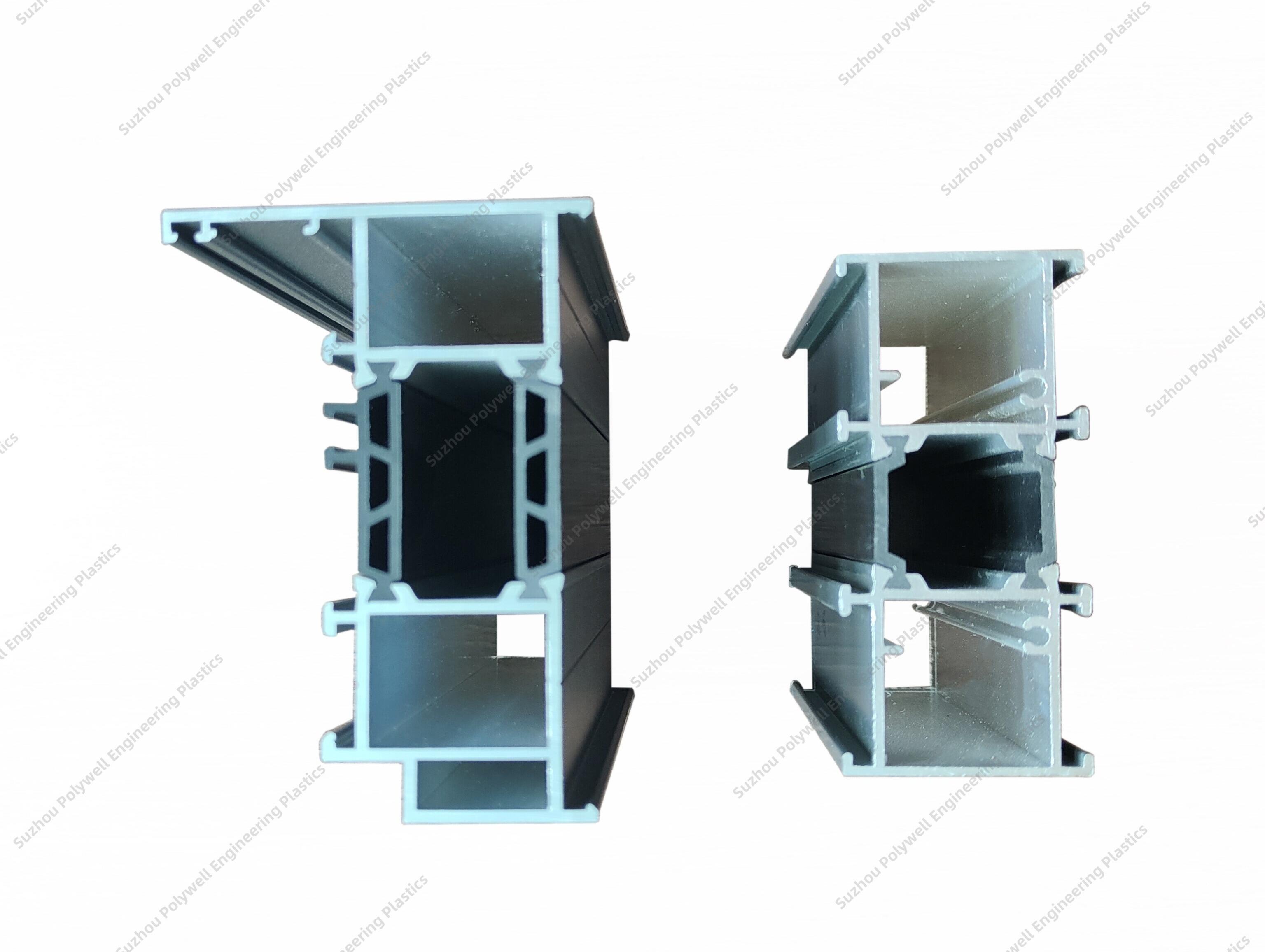

Aluminum windows have the disadvantage of limited thermal insulation. Its Uf value, which indicates the amount of heat that passes through a window profile, is simply too high. If your windows have standard aluminum profiles, your home may develop condensation or even mold. Besides the resulting high repair costs, household mold also aggravates respiratory problems such as asthma.

But that disadvantage has now been completely eliminated if you install polyamide strips in aluminum windows. In fact, thanks to the development of a new invention known as thermal break profiles, aluminum is at least as good as its competitors. In these profiles, produced with specialized machines, a polyamide strip is placed between the inner and outer sections of the profile.

Polyamide is a plastic that insulates more than 500 times better than aluminum, so thermal break profiles have a much lower Uf value and transmit much less heat or cold. As a result, your home stays warmer in winter while keeping the heat outside more easily in summer.

How to store polyamide thermal break strips?

First, store profiles horizontally in order to prevent bending or twisting the material; otherwise, long storage periods cause permanent sagging. Support long lengths.

Second, maintain ambient temperature in the range from 15 to 20°C.

Third, protecting against moisture.

Package

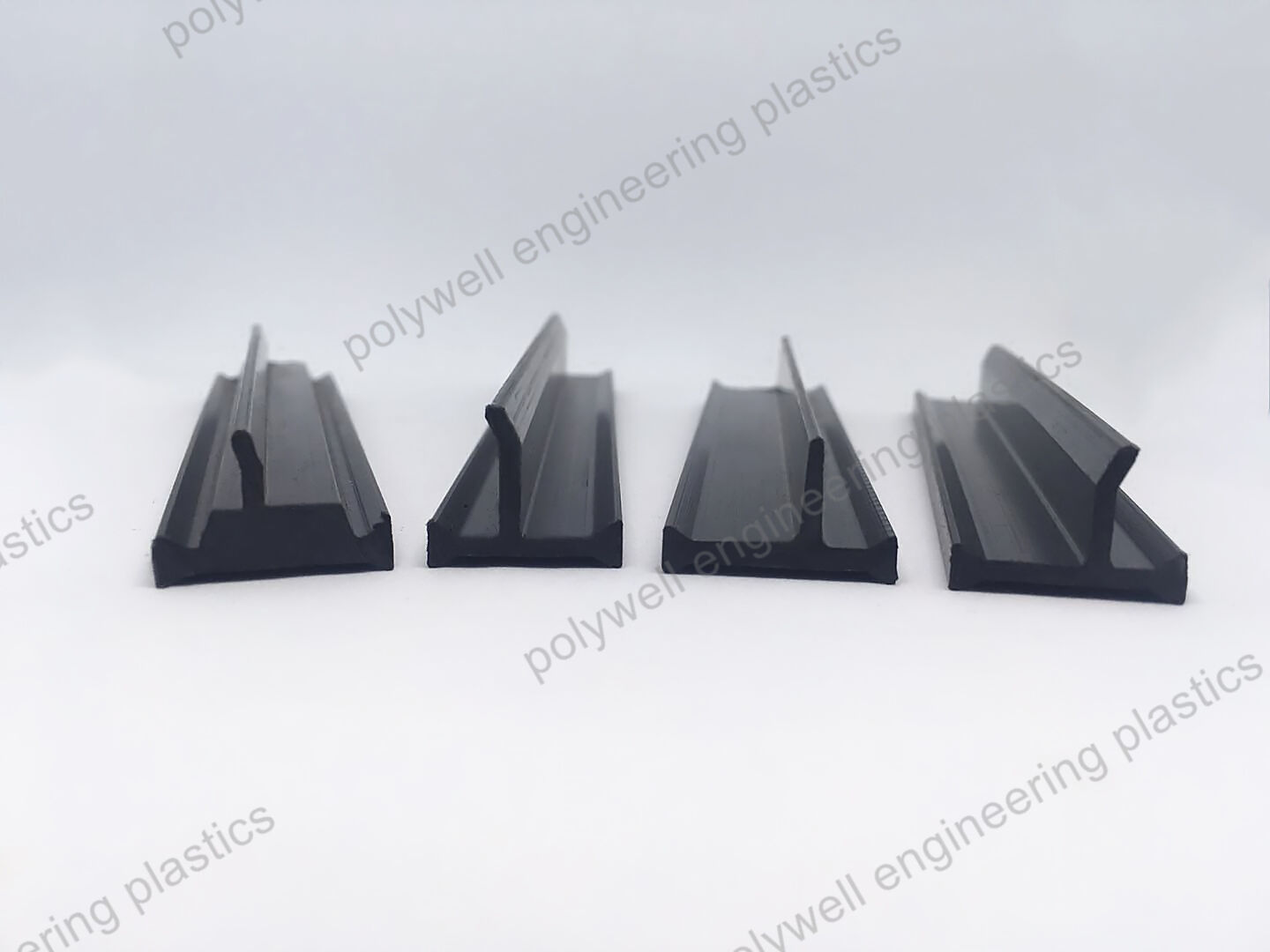

For all specifications/shapes, they could be packaged in linear, the length will be 6 meters or customized.

For the shapes "I" "C", and some simple shapes, they can be packed in rolls. The length usually is around 300-600 meters per roll.

Our service

1. Expertise in the production of standard polyamide thermal break strips.

2. Respect customers' needs, provide customized products, try best to satisfy customers' requirements.

3. Fast service and on-time delivery

4. Strict quality control system, each production process will be strictly supervised by us.

5.We can provide all products on the insulation strip production line and the technical support.

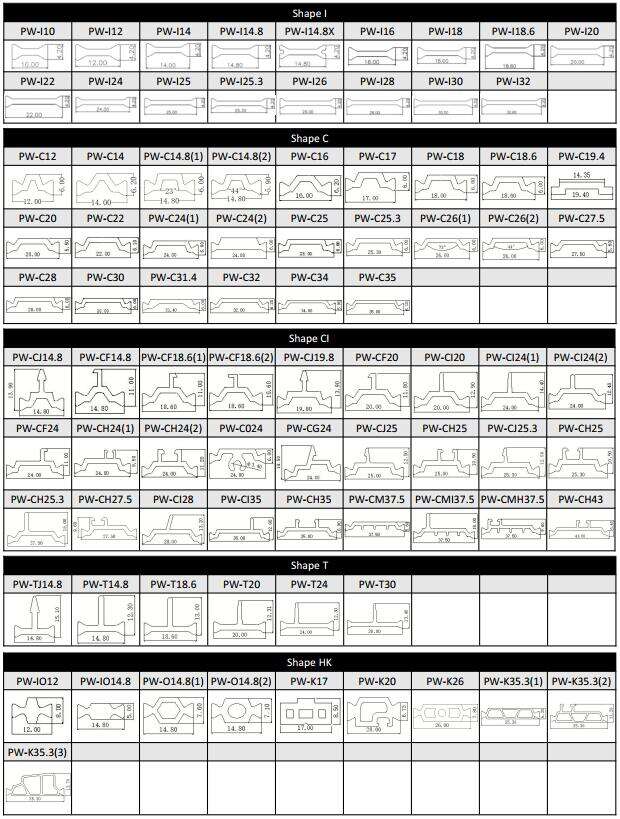

Different shapes:

Product Performance

Item |

Unit |

GB/T 23615.1-2009 |

PW-Technical specification |

Density |

g/cm3 |

1.3±0.05 |

1.28-1.35 |

Linear expansion coefficient |

K-1 |

(2.3-3.5)×10-5 |

(2.3-3.5)×10-5 |

Vicat softening temperature |

ºC |

≥230 |

≥233 |

Melting point |

ºC |

≥240 |

≥240 |

Testing for tensile cracks |

- |

No cracks |

No cracks |

Shore hardness |

- |

80±5 |

77-85 |

Impact strength(Unnotched) |

KJ/m2 |

≥35 |

≥38 |

Tensile strength(longitudinal) |

MPa |

≥80a |

≥82a |

Elasticity modulus |

MPa |

≥4500 |

≥4550 |

Elongation at break |

% |

≥2.5 |

≥2.6 |

Tensile strength(transverse) |

MPa |

≥70a |

≥70a |

High temperature tensile strength(transverse) |

MPa |

≥45a |

≥47a |

Low temperature tensile strength(transverse) |

MPa |

≥80a |

≥81a |

Water resistance tensile strength(transverse) |

MPa |

≥35a |

≥35a |

Aging resistance tensile strength(transverse) |

MPa |

≥50a |

≥50a |

1. Sample water content less than 0.2% by weight.

2. Normal laboratory condition: (23±2)ºC and (50±10)% relative humidity.

3. The specifications marked with "a" only apply to I-shaped strips; otherwise, the specifications agreed upon between the supplier and buyer through consultation shall be written in the contract or purchase order.

FAQ:

Q: What’s the difference between PA66 and PVC thermal break strips?

A: The PA66 thermal break strip can withstand higher temperatures, and its tensile strength and elongation at break are better than PVC, which means that it is not easily deformed or aged during continuous use.

PVC thermal break strips are easily aged and cracked under the influence of ultraviolet radiation and may soften and deform in high-temperature environments.

Q: Can you provide custom-sized thermal break strips?

A: Yes, we can. We can produce custom-sized strips based on the customer’s drawings.

Q: What’s the minimum order quantity (MOQ)?

A: Normally, our MOQ is 5000 meters.

Q: How long does it take to receive samples?

A: Around 3-4 working days.

EN

EN