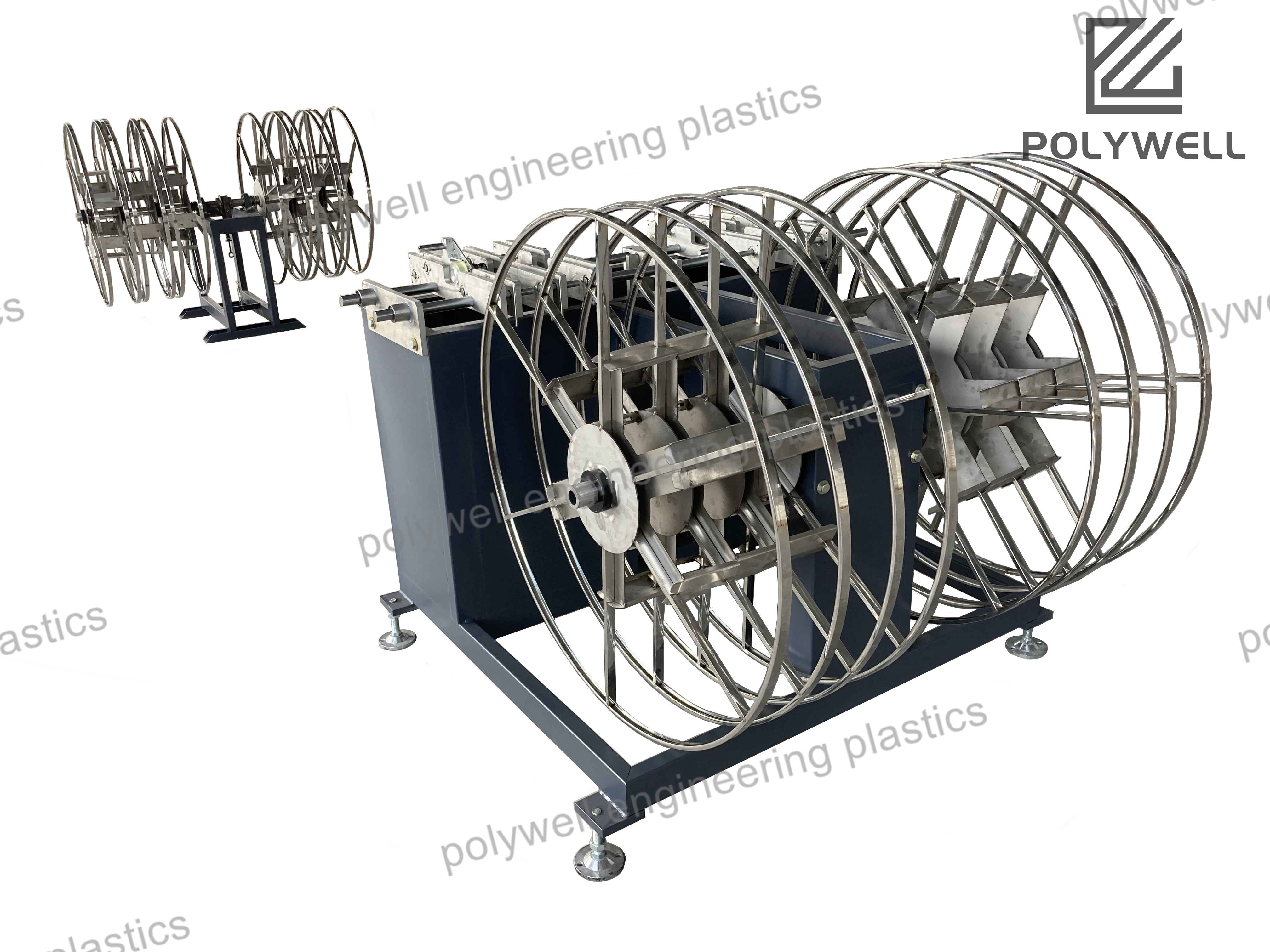

A profile rolling machine, in the context of plastic and polymer extrusion, is a specialized piece of equipment designed to wind continuous, flexible profiles onto spools or reels. It is a critical component in the post-extrusion handling process, enabling the efficient and damage-free coiling of products like seals, gaskets, trims, and thermal break strips for storage and transport. The machine operates by taking the linear profile from the extruder's haul-off unit and guiding it onto a rotating mandrel or drum. Its engineering focuses on two paramount factors: precise tension control and consistent layering. An adjustable servo or AC drive system manages the winding tension, which must be carefully calibrated; excessive tension can stretch or permanently deform the profile, compromising its cross-sectional geometry and functional properties, while insufficient tension results in a loose, unstable coil that is prone to tangling. To ensure a neat and uniform coil, modern profile rolling machines often feature traversing mechanisms that distribute the profile evenly across the width of the reel, employing either random or precision winding patterns. For profiles with complex geometries or a inherent tendency to twist, integrated straightening guides or dancing roller assemblies are used to maintain orientation. Constructed from robust materials to withstand continuous operation, these machines often include automatic cut-off and transfer systems for finished coils, linking seamlessly with downstream packaging equipment. By automating the winding process, a profile rolling machine safeguards product quality, maximizes production line throughput, reduces manual labor, and prepares the extruded profiles for the next stage in the supply chain, ultimately ensuring that the customer receives a product in perfect, ready-to-use condition.