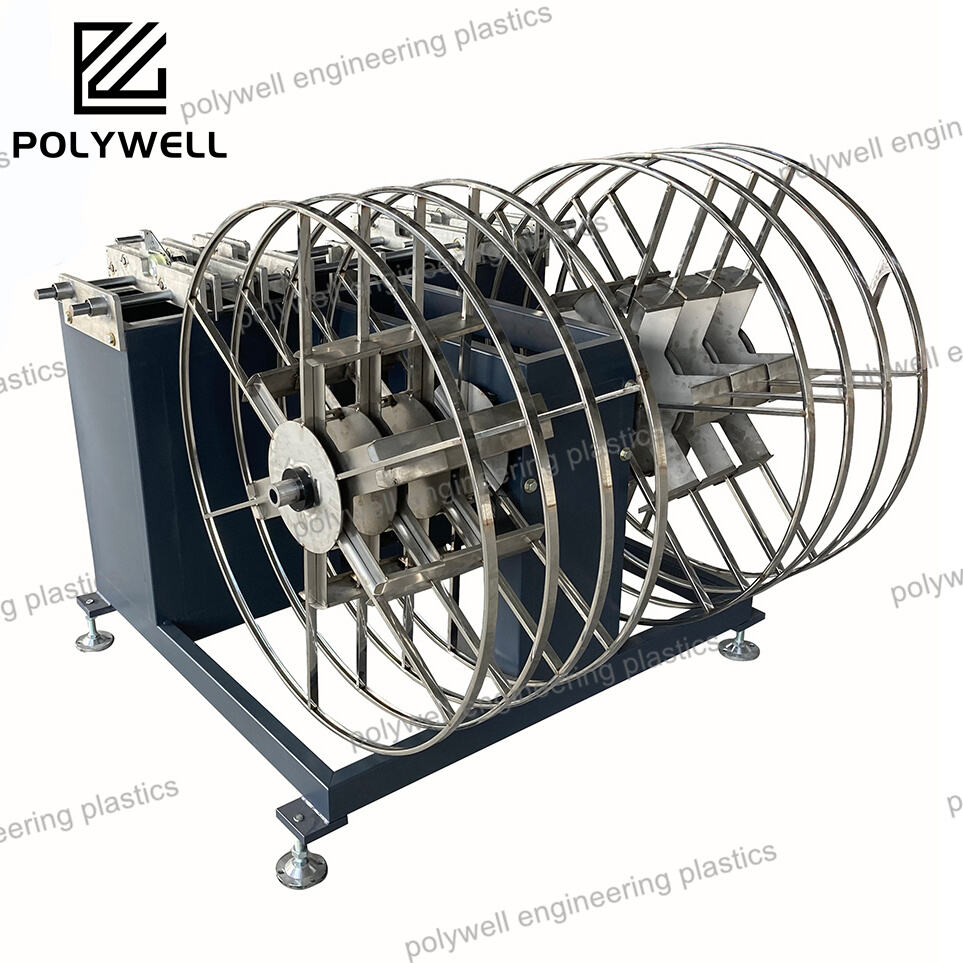

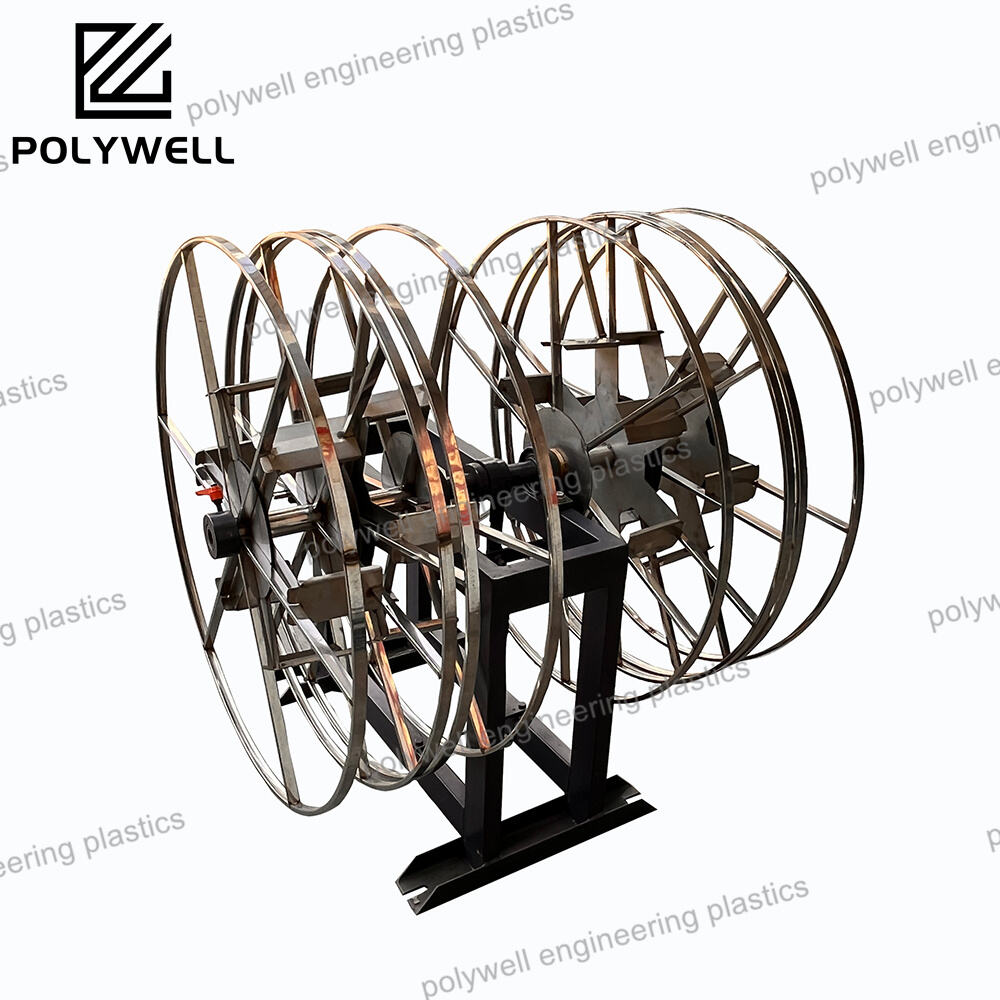

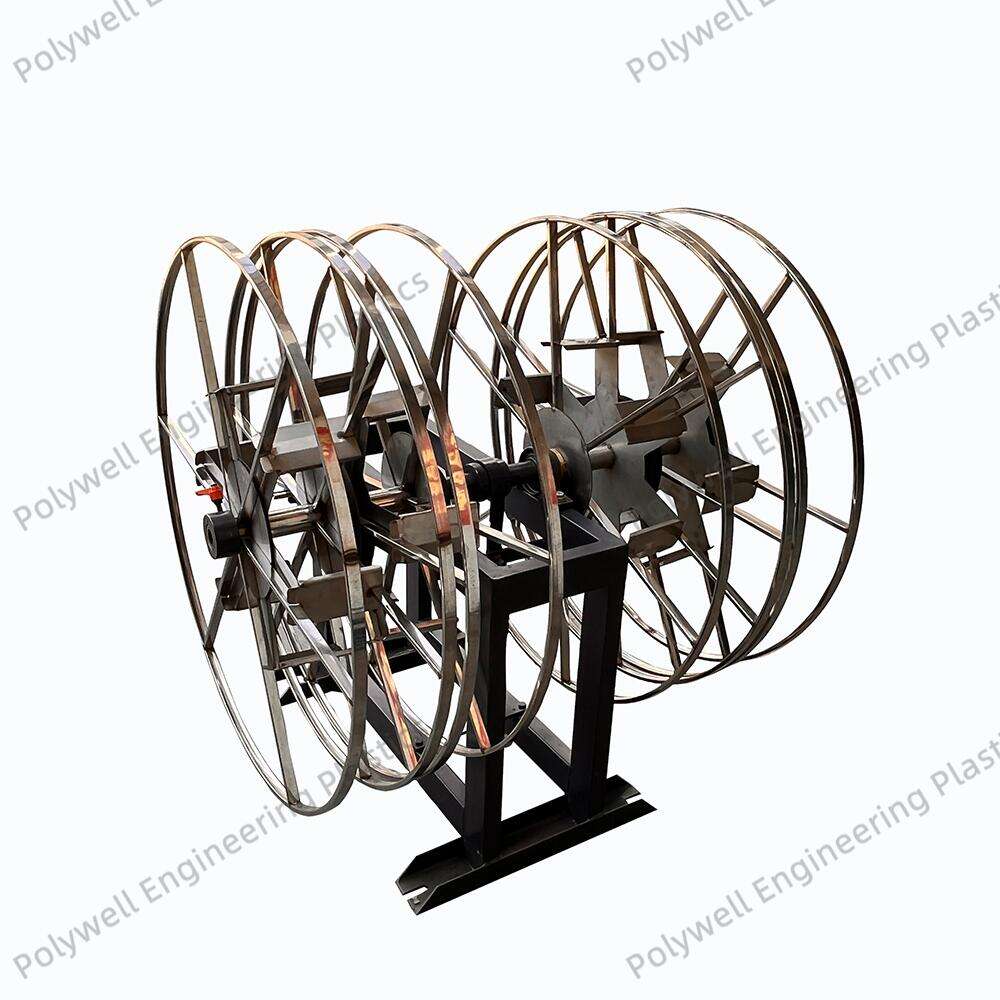

A profile wrapping machine is a specialized type of packaging equipment designed to apply a protective wrapping around long, continuous extruded profiles. While sometimes used to refer to machines that apply decorative vinyl films to rigid profiles like PVC window frames, in a packaging context, it typically describes a system that wraps flexible coiled profiles. This process is essential for protecting delicate surfaces from scratches, dust, and moisture during storage and shipment. The machine operates by feeding a coil from a winder into a wrapping station, where a film—most commonly stretch wrap or a pre-stretched polyethylene film—is spirally wound around the coil's circumference. The key to a effective wrap is consistent film tension and overlap, which creates a tight, secure bundle without compressing and damaging the profile within. More advanced versions of this machine may use shrink film, where the wrapped coil then passes through a heat tunnel, causing the film to contract tightly around the product, forming a robust, tamper-evident, and weather-resistant seal. These machines are highly automated, often equipped with PLCs for setting wrap count, film tension, and rotation speed. They may also include integrated film dispensers and cutters. The advantages of implementing a profile wrapping machine are numerous. It significantly enhances product protection compared to manual wrapping, reducing waste and costs associated with damaged goods. It improves packaging consistency and presentation, boosts packaging line throughput, and can reduce material usage through optimized film control. For manufacturers supplying to exacting industries like automotive or construction, this machine is a vital investment in quality assurance, ensuring that products such as rubber seals or polymer thermal breaks arrive at their destination in pristine, factory-fresh condition.