Winding machines are undoubtedly essential in the processes of the production of thermal break strips. Thermal break stripes are therefore used in modern constructions especially in windows and doors to enhance energy efficiency. Winding machines are used in remarkable manufacturing industries such as POLYWELL to create thermal break strips needed during building insulation.

Setting Up the Thermal Break Strip Production and the Machines Used

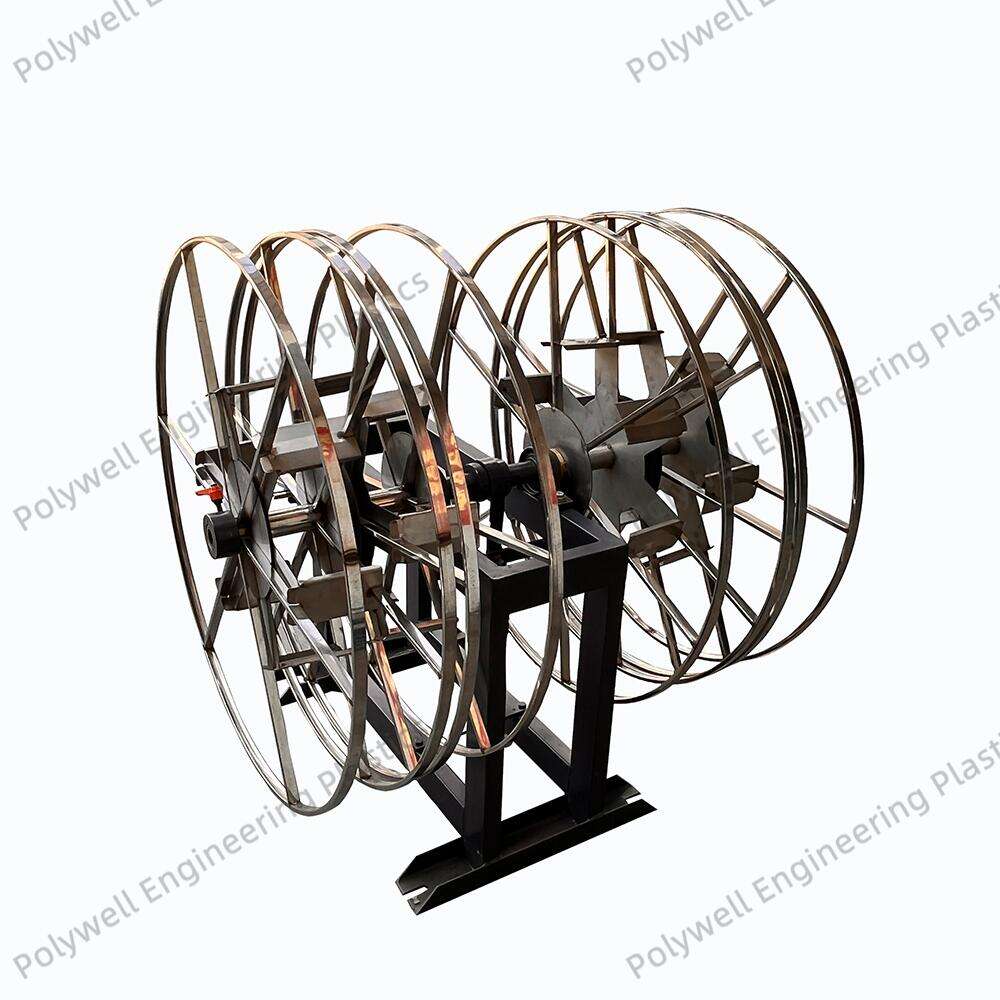

Winding machines are vital for rolling thermal break strips onto spools. This enables the cord to be wound up tightly and uniformly which is critical for the functionality of the strip. These machines also guarantee that each screened strip has the right weight with accurate lengths and a smooth toning. POLYWELL winding machines are designed to work at high speeds which results in shorter processing times while maintaining accuracy.

Advantages and Unique Characteristics of POLYWELL’s Winding Machines

POLYWELL’s winding machines have certain requirements which are designed for thermal break strips. For instance, the field speed and chamber tension adjustments ensure that roller transfer strips are seamlessly and closely wound. This ensures that the chances of strip damage are minimized and consistent roll quality;

this, in turn, is essential for the performance of the roll during its operation.

The Benefits of Winding Machines in Material Handling

Working with thermal break strips by hand is a labor-intensive task. Winding machines, on the other hand, assist in easing this burdensome job by mechanizing the winding process. The materials are not stressed nor misplaced in other ways due to POLYWELL’s machines. The strips, in this manner, are preserved in a condition fit for use in any construction projects.

The Importance of Winding Machines in the production of a variety of Products

Moreover, in every product, there is a need to maintain uniformity. Winding machines at POLYWELL ensure that all the thermal break strips are wound in the same way. Such a uniformity helps to maintain the energy performance of the thermal break strips. A fast and accurate winding process improves the insulation of the building, thereby reducing energy costs.

Winding machines provided by POLYWELL enhance the quality of winding and consistency of thumb break strips. With the development of better winding equipment the manufacturers will be able to produce better quality products that will be suitable for the present economy saving buildings.