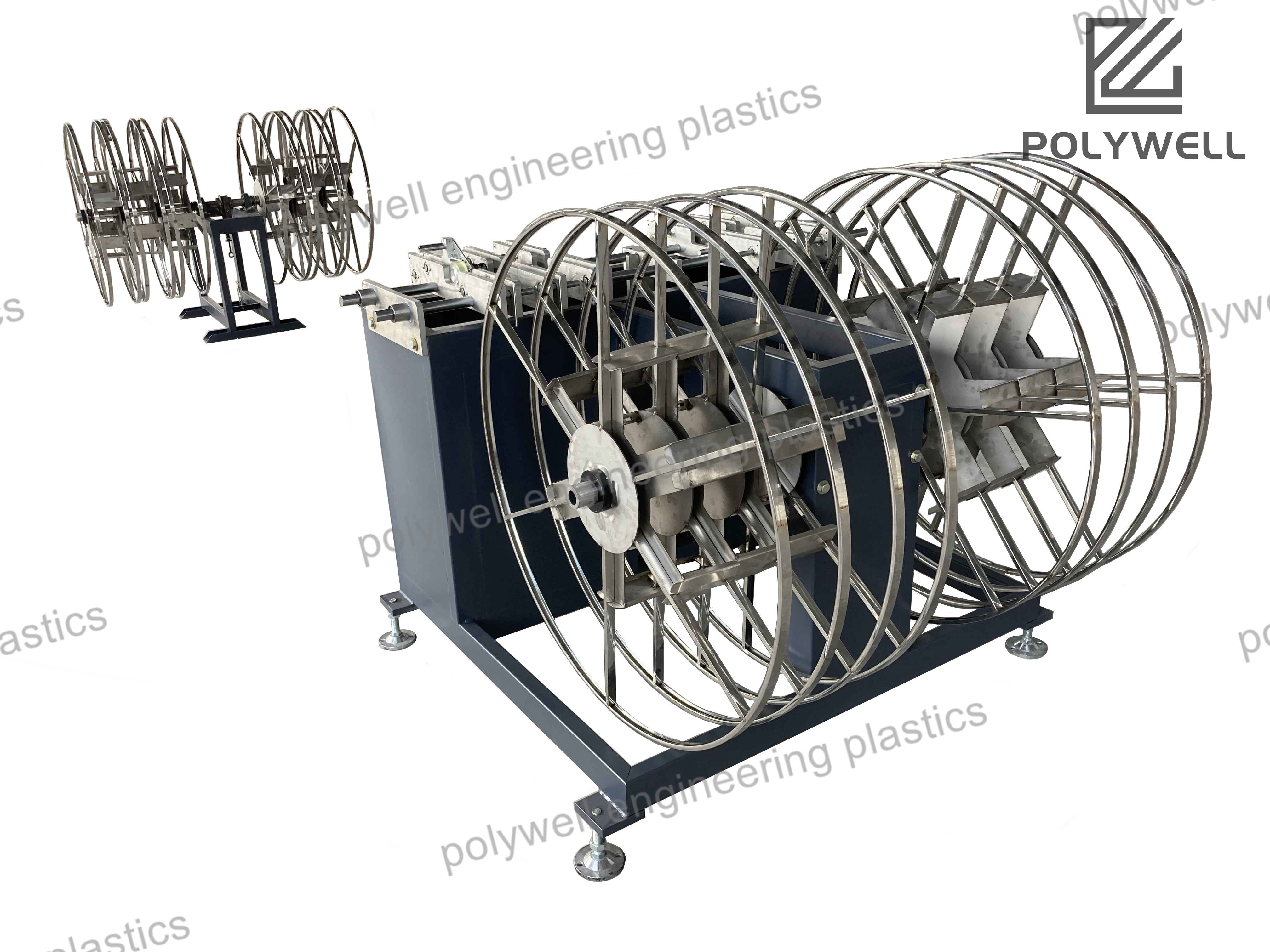

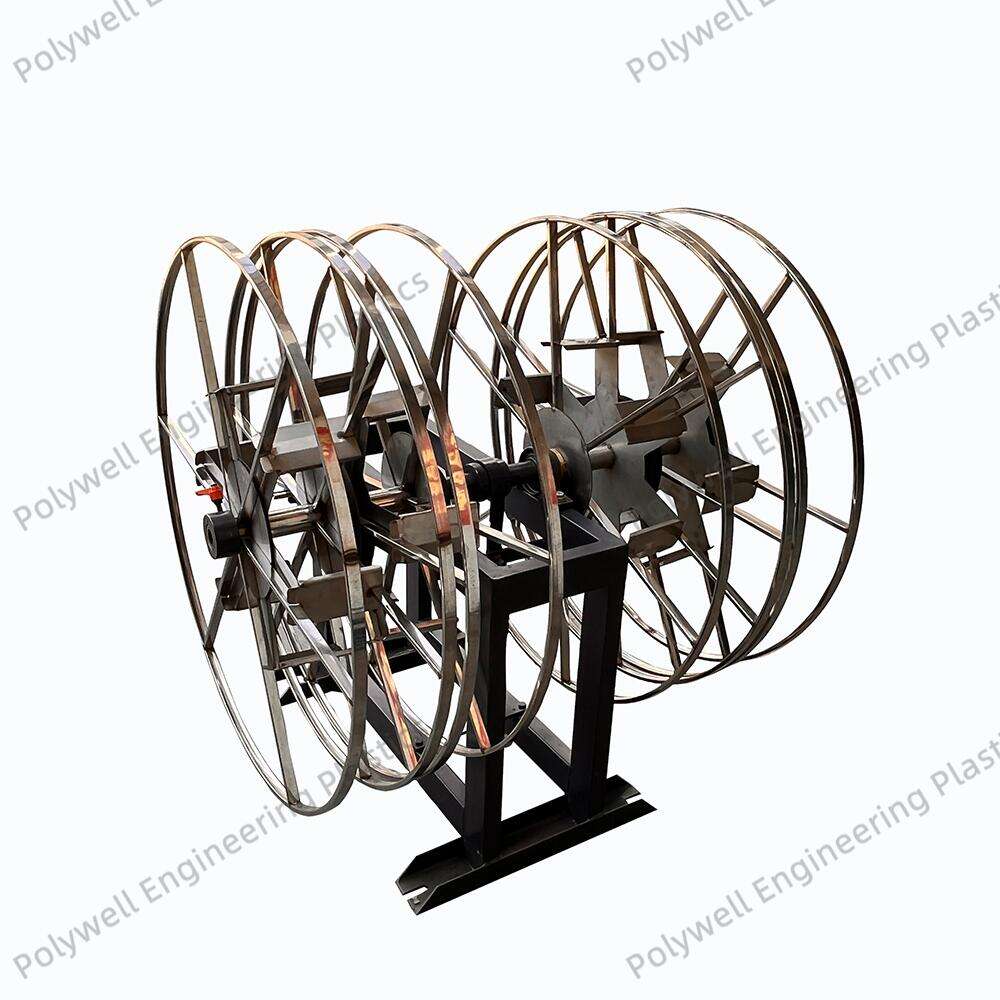

Winding equipment encompasses a broad category of industrial machinery dedicated to coiling long, flexible materials—such as wires, cables, hoses, textiles, and extruded polymer profiles—onto spools, reels, or cores. In the plastics and extrusion industry, this equipment is indispensable for handling the continuous output from extruders, transforming it into manageable, organized units for storage, transportation, and further processing. The fundamental components of winding equipment include a payout or feeding system, a tension control mechanism, a winding mandrel, and a drive system. The sophistication of this equipment can range from simple, manually operated winders to fully automated, PLC-controlled systems integrated directly into the extrusion line. Key differentiators in performance are the precision of tension control and the winding pattern. Advanced systems use closed-loop tension control with feedback from dancer arms or transducers to apply a consistent, minimal tension, which is crucial for preserving the dimensional integrity of sensitive profiles like foam gaskets or complex sealing lips. The winding pattern, whether random or precision, affects the coil's stability and ease of unwinding. For extruded profiles, traverse winders are common, as they neatly lay the material side-by-side across the reel's width. Modern winding equipment often features modular designs, allowing for customization with add-ons like pre-straighteners for twisted profiles, automatic core loading, length measurement systems, and in-line defect detection. The primary benefits of utilizing professional winding equipment are enhanced product quality and operational efficiency. It prevents product damage such as kinking, stretching, or deformation, reduces labor costs, increases production speed, and ensures a consistent, high-quality package that facilitates automated handling at the customer's facility, thereby solidifying its role as a critical link in a modern manufacturing workflow.