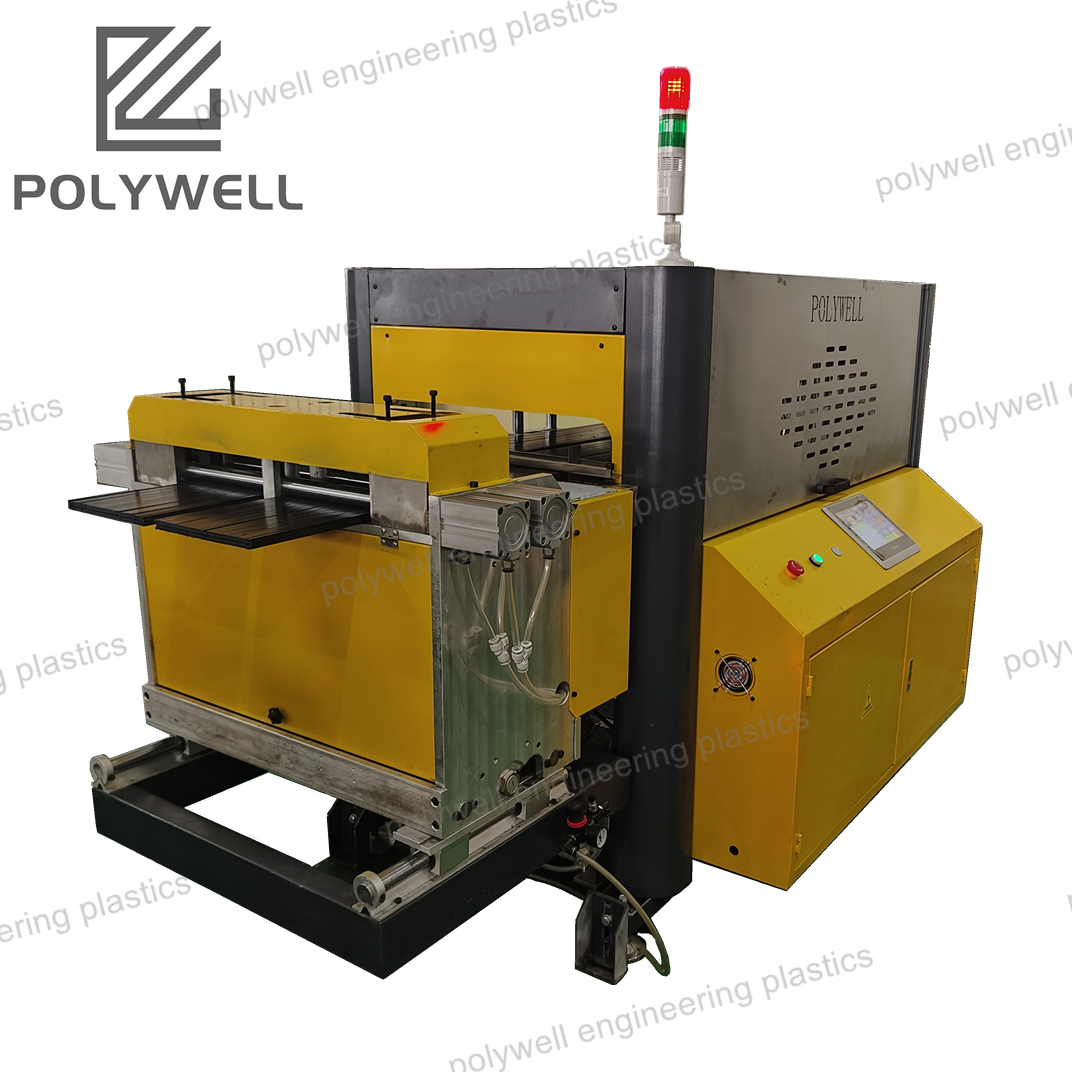

A plastic cutting machine is an industrial apparatus specifically engineered for the precise and efficient severing of plastic materials, ranging from flexible films and sheets to rigid profiles and heavy-duty blocks. The technology employed varies significantly based on the material properties, desired cut quality, and production volume. For semi-rigid and rigid extruded profiles, such as those made from PA66 used in thermal break applications, computer-controlled circular saws are predominant. These machines feature high-speed tungsten carbide-tipped blades, precision linear guides, and servo-driven feed systems to ensure square, burr-free cuts with tolerances within fractions of a millimeter. Key technical considerations include the blade's tooth geometry, which is optimized for different polymers to prevent melting or chipping, and the clamping system, which must securely hold the profile without causing deformation or surface marring. For thinner plastic sheets or films, guillotine cutters or laser cutting systems are used, the latter offering exceptional precision and a sealed edge but at a higher operational cost. Advanced plastic cutting machines are often integrated into automated extrusion lines, functioning as a downstream unit. They are synchronized with the extruder's haul-off speed and are equipped with measuring devices that trigger the cut at pre-determined lengths. This automation is crucial for mass production, ensuring consistent part length, reducing labor, and minimizing material waste. Furthermore, modern machines incorporate dust extraction systems to manage plastic particulates and user-friendly Human-Machine Interfaces (HMIs) for quick changeover between different product specifications. The selection of an appropriate plastic cutting machine is therefore critical for maintaining product quality, optimizing production efficiency, and ensuring the dimensional accuracy of finished components like thermal break strips before they are assembled into final window or door systems.