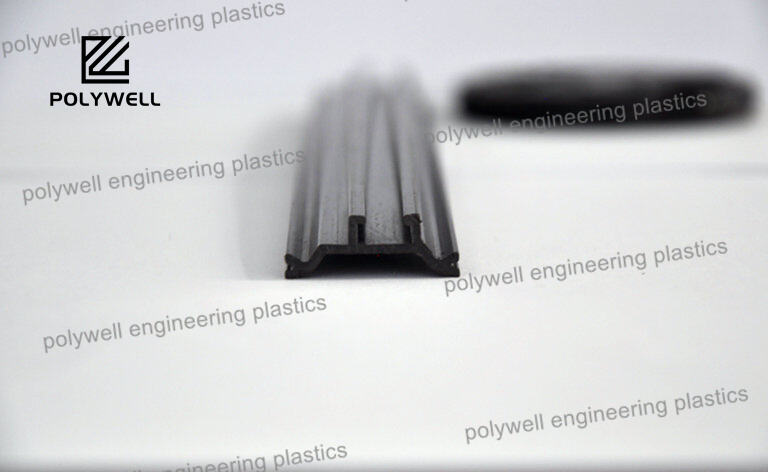

A thermal bridging insulation strip is a critical building component designed to mitigate thermal bridges—areas where heat easily escapes or enters a structure—by incorporating materials with low thermal conductivity, such as PA66, to enhance energy efficiency and comfort. These strips are commonly used in window and door frames, balconies, and structural connections, where they break the path of heat flow, reducing overall U-values and preventing condensation that can lead to mold or structural damage. The choice of materials like PA66 is strategic due to its thermal conductivity of approximately 0.25 W/m·K, combined with high mechanical strength and durability that withstands environmental stresses like temperature fluctuations, moisture, and UV exposure. This ensures long-term performance without compromising structural integrity, often exceeding decades in service life. The design of these strips involves engineering profiles that maximize insulation while maintaining compatibility with other building elements, such as aluminum or steel frames, and they may include features like tongue-and-groove joints for easy installation. Manufacturing processes like extrusion allow for custom shapes and sizes, with quality checks per standards like EN 14024 for thermal break performance. Beyond energy savings, thermal bridging insulation strips contribute to sustainability by lowering carbon footprints through reduced heating and cooling demands, and they align with green building certifications like LEED or BREEAM. In cold climates, they prevent heat loss and ice dam formation, while in warm regions, they reduce cooling loads, making them versatile for global applications. Innovations include the use of composite materials or smart integrations for monitoring thermal performance, and ongoing research focuses on improving fire resistance and recyclability. Overall, these strips are indispensable in modern construction for achieving thermal comfort, cost savings, and environmental goals, driven by advancements in material science and building codes worldwide.