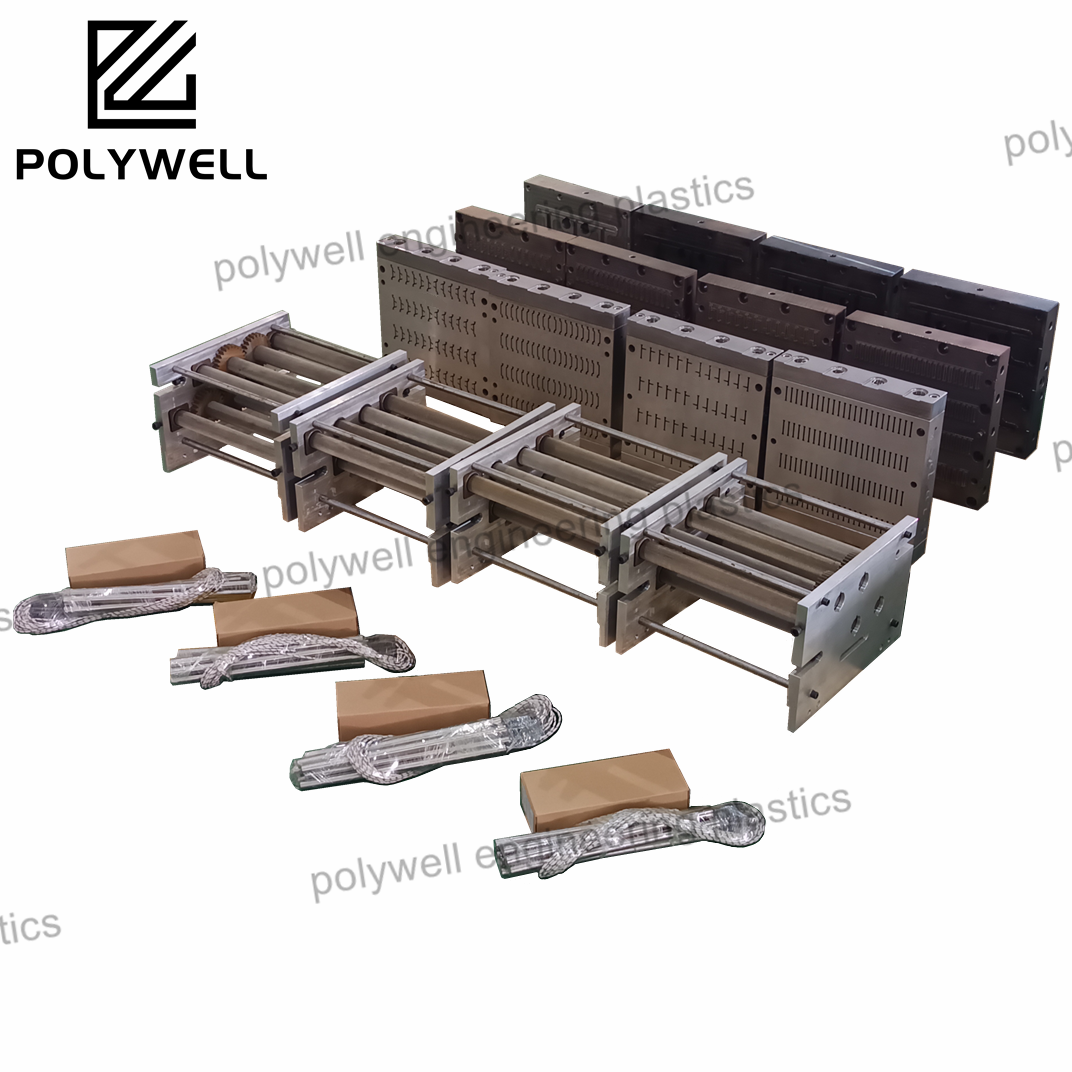

Extrusion molds are especially important for making high-quality thermal insulation strips, especially those made of PA66. POLYWELL is a well-known name in this industry, which manufactures molds for specific thermal break profiles.

What are Extrusion Slices and How Are They Used

Extrusion molds are the foundation of any thermal insulation stripping. While as standard molds, they are complex in nature since they take into account the behavior of the material being stripped and its dimensions after the production. However, due to the high shrinkage rate of materials, there are intrinsic issues that PA66 thermal strip extrusion faces.

How Shrinkage Affects PA66 Materials

PA66 materials are prized in this industry for their mechanical and thermal properties especially in thermal break strips. Aligned to that however, is the significant shrinkage that occurs during cooling which makes it hard to maintain precise dimensions. This is why it is important to control elastic factors during the design and manufacture of molds.

The Importance of Proportional Scaling

Currently POLYWELL’s expertise is not limited only to the molds but goes a step further to design molds with accurate proportional scaling in order to combat the shrinkage of PA66. This comes without the reliance of just the dimensions that the customers provide, where shrinks are predicted and compensated using engineering techniques. The dimensions on the cold mold are purposely increased according to the calculations and over decades of practice.

Why Experience Matters

Determining the wise proportional scaling is not a decision that can be made easily, for it takes vast experience and technical knowhow. It is this constant improvement in Proportional Scaling that allows each mold created by POLYWELLs team of engineers to meet the quality standard that POLYWELL sets. This allows customers to fabricate thermal insulation strips with the least variance in dimension and thus improves the performance of the products in general.

Extrusion mold manufacturing for PA66 thermal strips is a developmental project which requires thorough understanding of the properties of materials combined with engineering. Going for POLYWELL molds will enable the users get in the reach of the best technology available in the production process enhancing their thermal break profiles in terms of quality and performance.