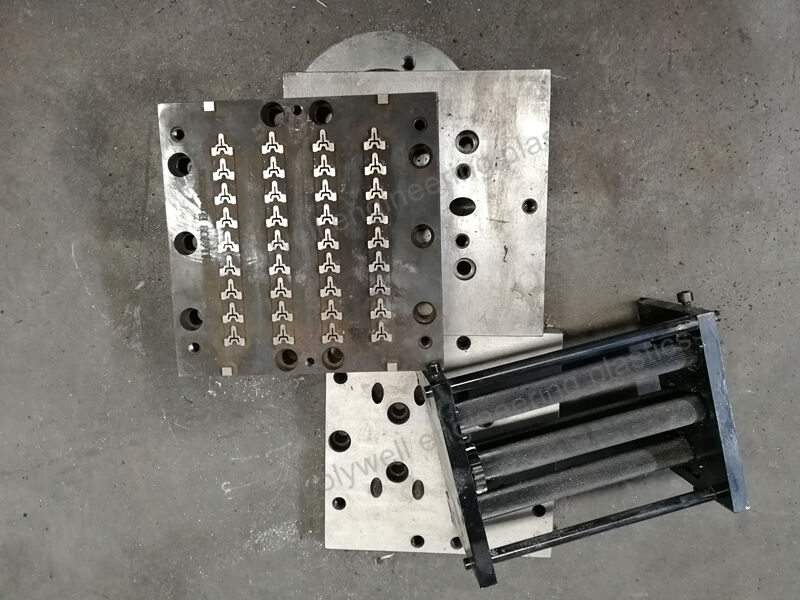

Nylon Extrusion Steel Mold for Polyamide Thermal Break Strips PA66 Strip Extrusion Mould

Extrusion Nylon Chain Guide PA66 Runway Guide Polyamide Rail Guide Mold

- Overview

- Recommended Products

Products Details

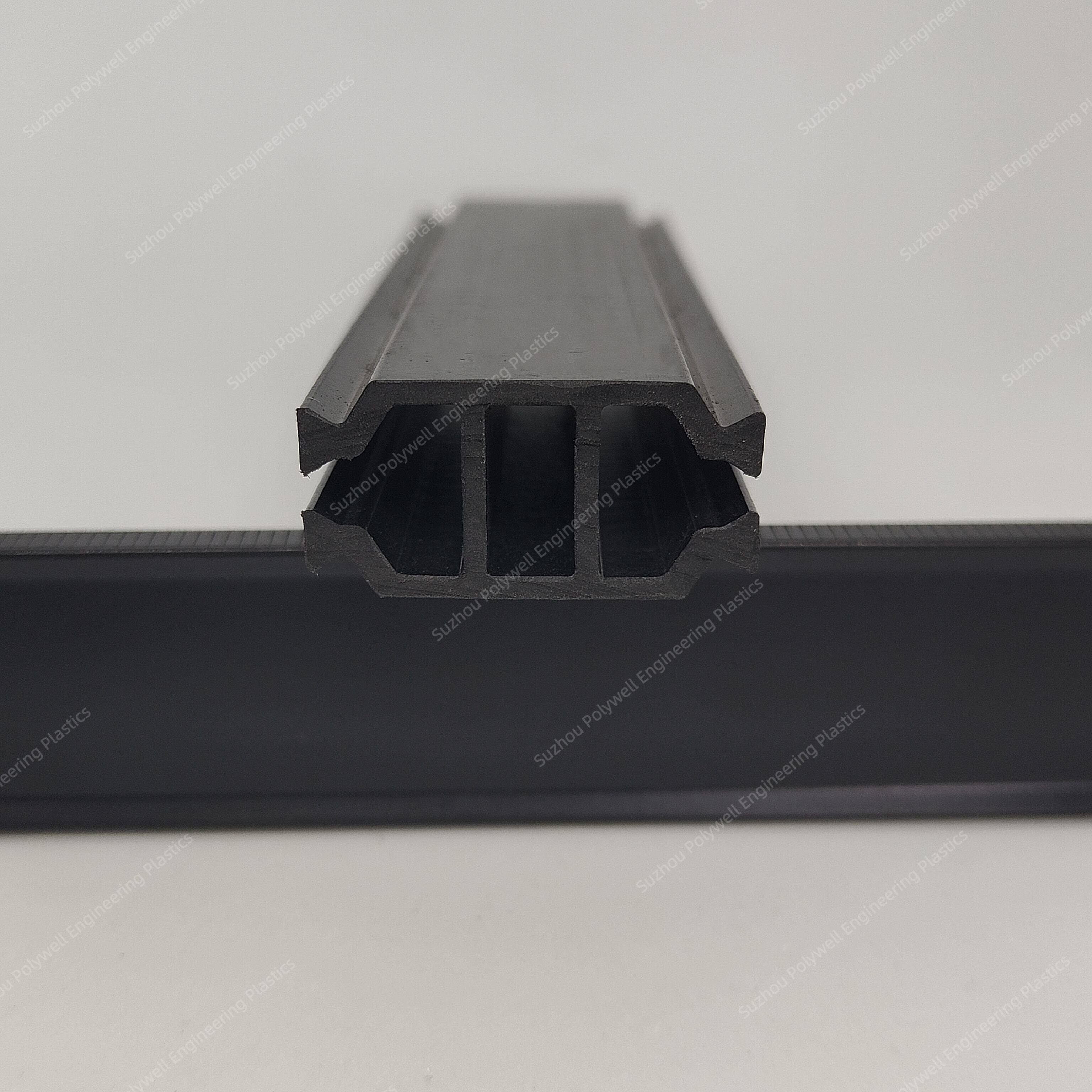

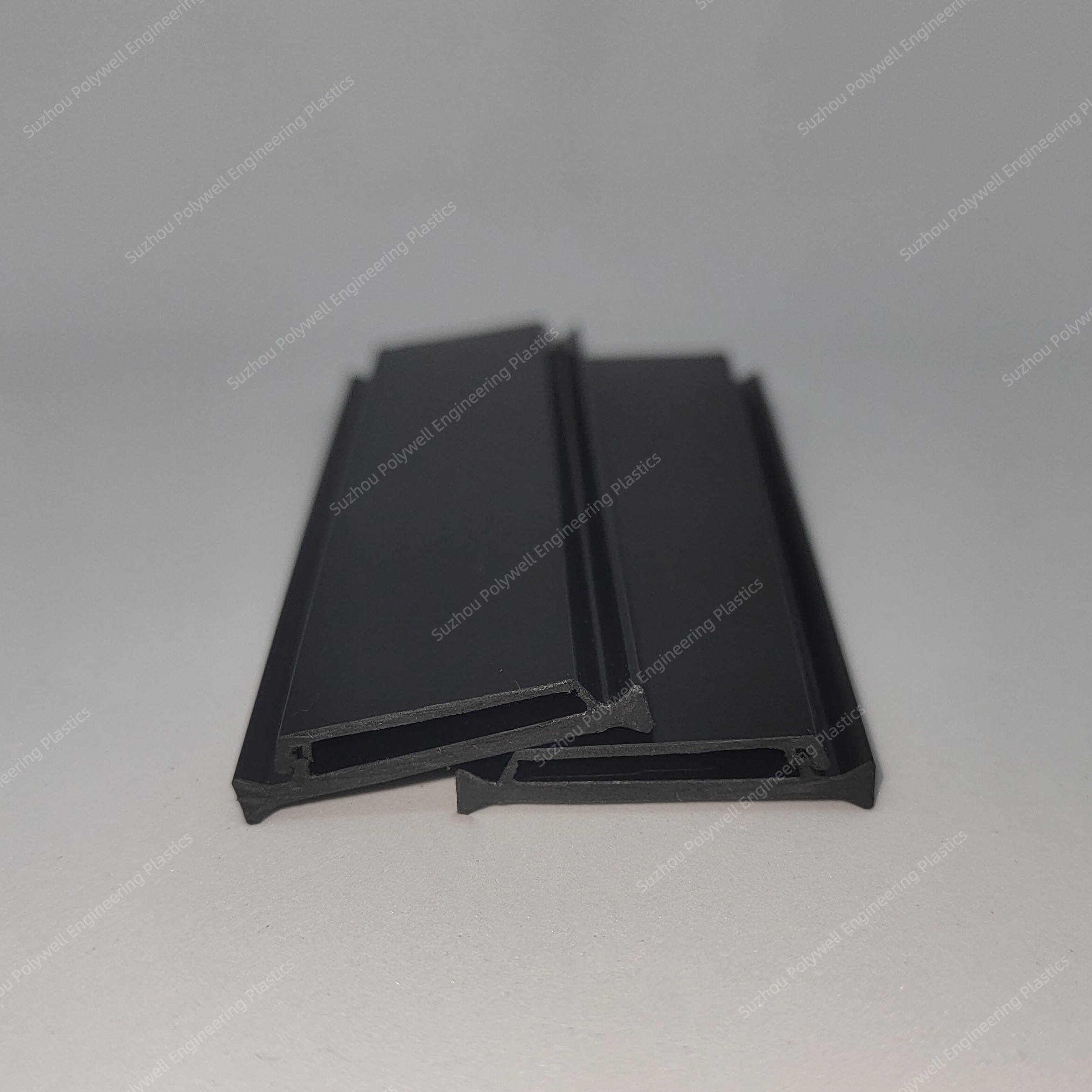

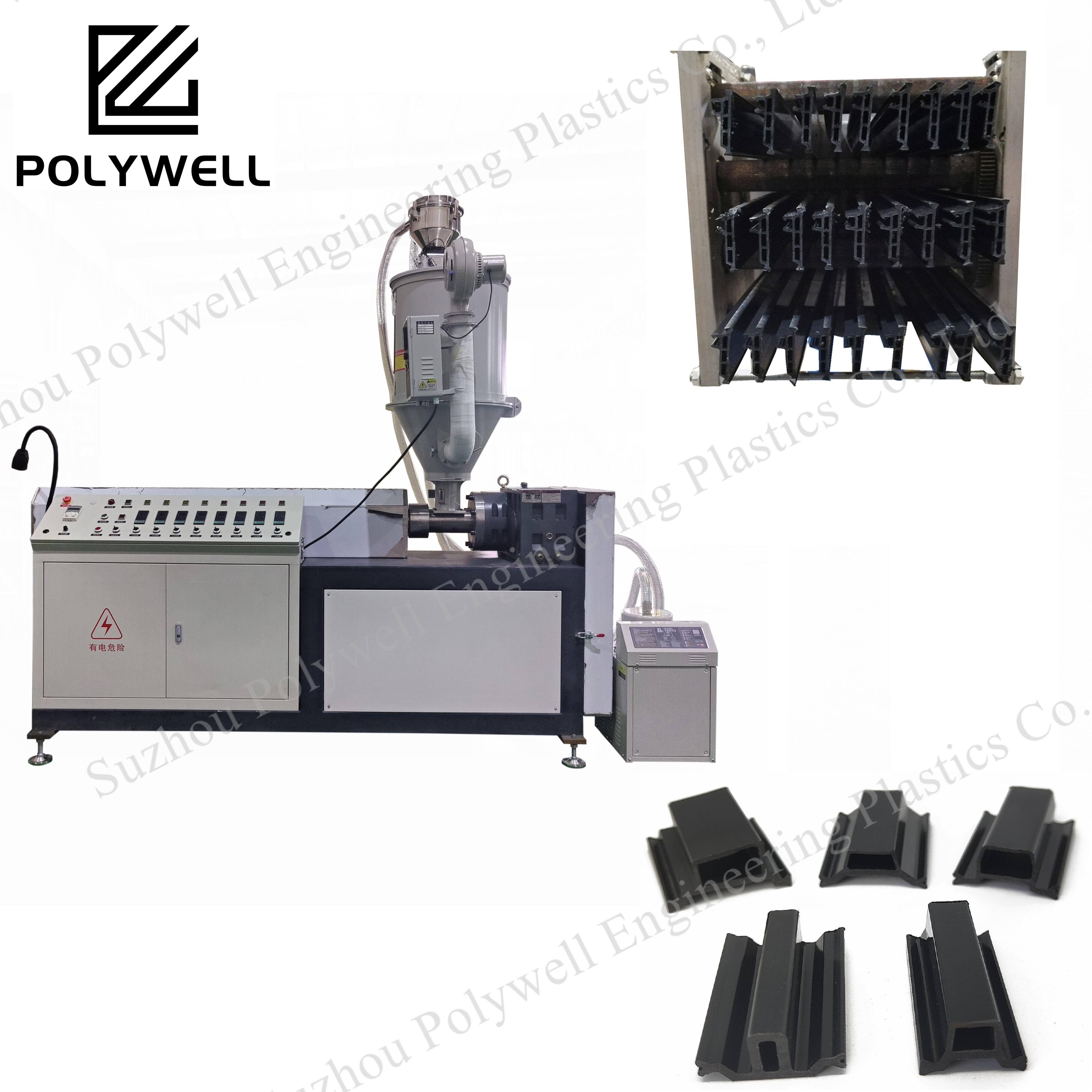

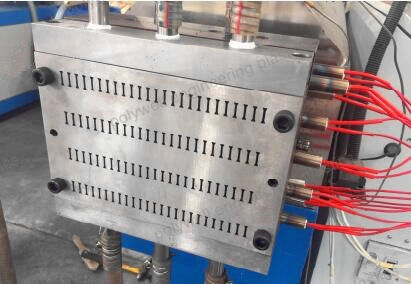

Mold plays a crucial role in the production of PA thermal break strips. It is an essential component that ensures the final product meets the required specifications. Installed on a single screw plastic extrusion machine, the mold facilitates the shaping and formation of the strips. By carefully controlling the temperature and pressure, the mold enables the plastic material to be extruded into the desired shape and size. This precision is vital in achieving the high-quality thermal break strips that are used in various applications. Without the mold, the production process would be incomplete, highlighting its significance in the manufacturing of PA thermal break strips.

Thermal break profile extrusion molds are always equipped on single screw plastic extruding machine. They are used for producing and shaping PA thermal break strips.

What is mold in manufacturing?

Mold, also spelled mould, tool or die. In manufacturing, a cavity or matrix in which a fluid or plastic substance is shaped into a desired finished product. A molten substance, such as PA 6.6 material, is poured or forced into a mold and allowed to harden.

Plastic extrusion molding is the most commonly used method for making plastic products. Extrusion molding is a method in which molten plastic usually a thermoplastic is poured into a metal mold composed of steel or aluminum. Once the molten material has been put into the mold, it must be allowed to cool until it solidifies before the final item can be extracted. Molding materials including ABS, acetal, nylon 66, low-density polyethylene (LDPE), high-density polyethylene (HDPE), polycarbonate, polypropylene, polystyrene and thermoplastic elastomer are used. Plastic extrusion molding is used in a variety of industries including construction, food and beverage, medical and pharmaceutical.

And our company mainly manufactures molds for nylon 66 products.

Name |

PA heat insulation profiles mould |

Plastic material |

PA66-gf25 |

Steel of Cavity & Core |

DIN 1.2379 |

Numbers of Cavity |

Customized |

Hardness of Cavity & Core |

48-52HRC / 55-60HRC |

Mould Accessories |

HASCO Standard |

Cooling system |

Water cooling |

Runner |

Cold |

Delivery time |

Around 28-35 working days |

Packing |

Plywood case |

Payment |

T/T, Western Union, Money Gram |

Our service of mold design and development:

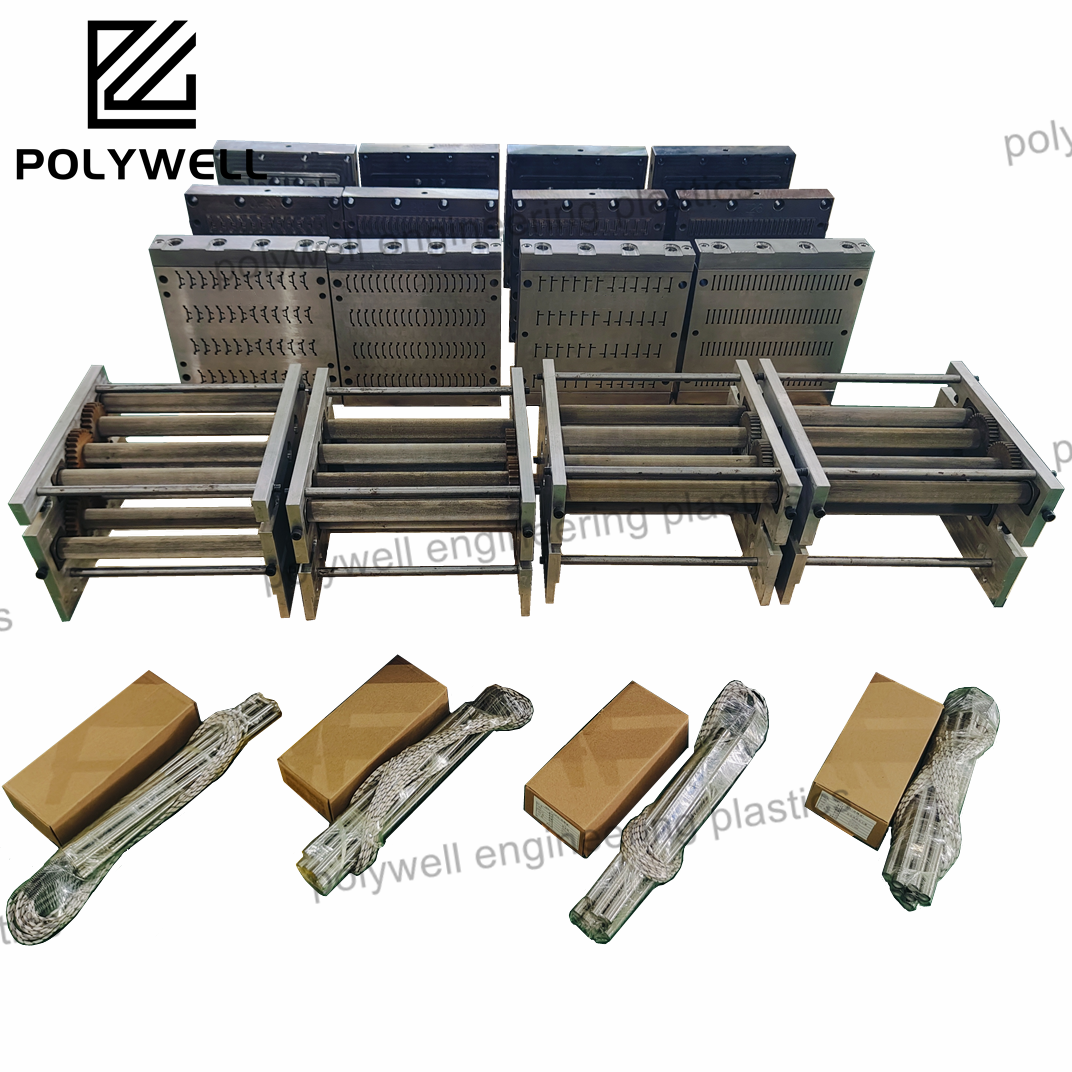

The precision of the tool is the key to the quality of the part. Tool making is an art. That's why we manufacture and test our tools to the strictest quality standards. Whether you need a tool for prototyping or high volume multi-cavity production, we will get it done quickly and accurately.

Packing & Delivery

We usually put each mold into a plywood case to make sure the mold is safe during the whole transport process.

The weight of each mold is around 60-200kg. It depends on the mold sizes.

We usually need 28-35 working days to produce a mold. After that, we will do the mold test to make sure both the mold and the polyamide strips produced by this mold are qualified.

EN

EN