Heat loss is minimized significantly by thermal break strips which help improve a building’s energy performance. These strips are produced using highly sophisticated processes such as the single screw extruder which is accurate and efficient.

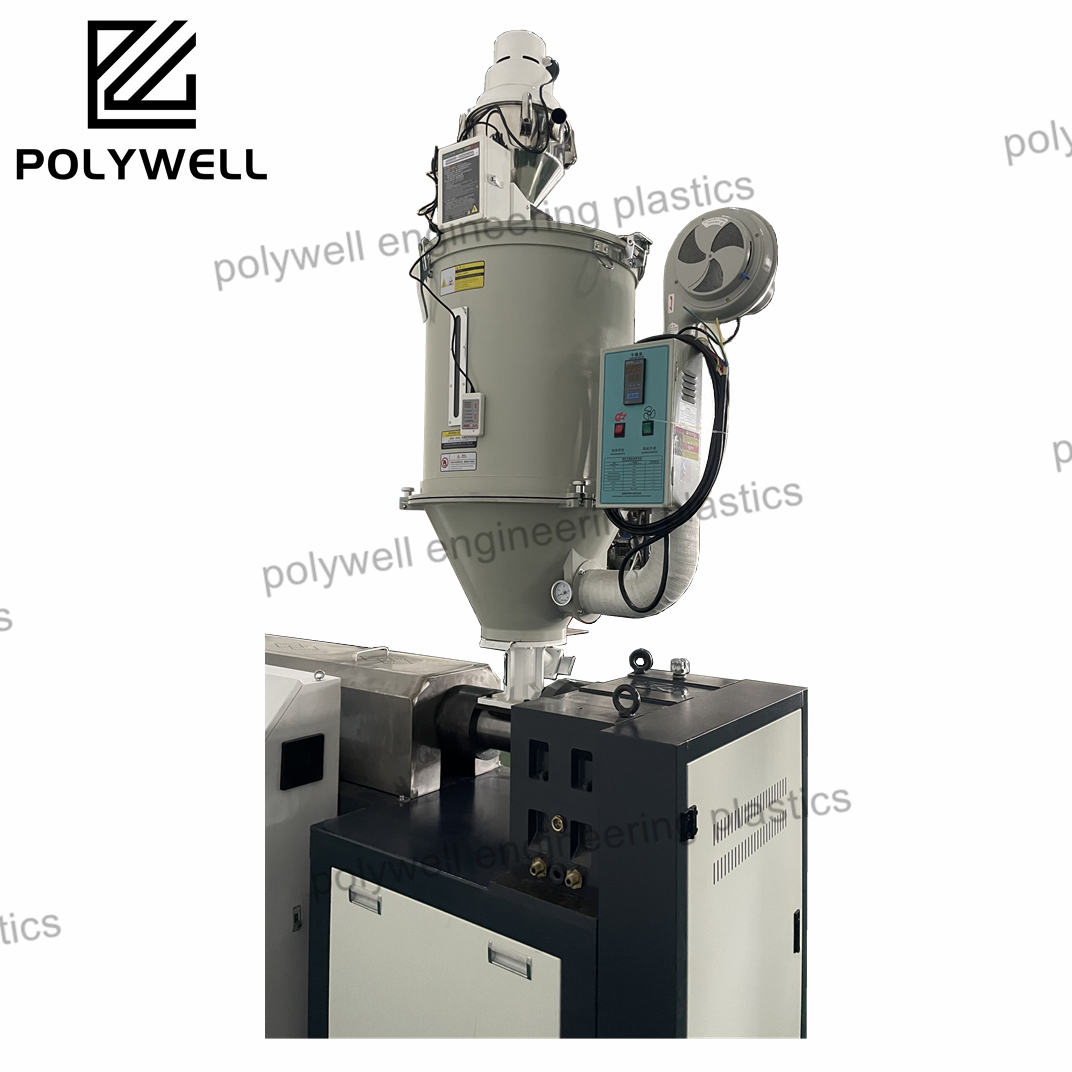

What is a Single Screw Extruder? A single screw extruder is a type of machine that converts raw materials or scraps such as plastic into a desired end product through a barrel which contains a rotating screw. For POLYWELL’s single screw extruders, the machine is specifically designed to produce thermal break strips that are used in the construction industry.

The Role of Single Screw Extruders in improving Thermal Break Strip Production:

The uniform performance during extrusion: The quality of thermal break strips that is manufactured can be determined by the design of the extrusion process. As the heat is applied, it is maintained in an optimal state and through constant pressure and flow, the strips are extruded.

Thermal Efficiency: There is considerable energy savings in the buildings because of the heat transfer which is prevented by the thermal break strips, made by POLYWELL’s extruders. The thermal insulation of the strips is therefore not compromised by single screw extruder’s poor thermal management.

Requisite Precision in Dimensions: In order for them to be effective, thermal break strips application has very stringent dimensional requirements. The single screw extruders in POLYWELL are constructed even in accuracy so that each strip has the precise performance specification.

Types of Thermal Break Strips Produced: Single screw extruder by POLYWELL is capable to manufacture different types of thermal break strips for example rigid PVC or rigid rubber thermal break strips. This type of plastic profiles are especially designed for the windows and doors, curtain walls and other construction parts which need thermal protection.

Advantages for Manufacturers: There is extensive range of those benefits for the producers.

High Quality Output: Anti Thermal Break ThermoRubber strips from POLYWELL’s single screw extruders offer good performance thanks to their quality control and quality assurance standards during manufacturing.

Reduced Downtime: The machines are also constructed with simple maintenance procedures resulting to less idle time and increased production.

Energy-Efficient: Designated extruders can lower the amount of energy needed for successful operations while ensuring excellent output performance.

Single screw extruders are crucial in the production of thermal break strips for efficient building components. Using the advanced technology of POLYWELL, the manufacturers will be in a position to produce exact thermal break strips, which are critical for insulation and energy efficiency in modern constructions. Furthermore, by using these extruders, the companies are able to improve product quality and productivity.