Nylon Profile Extruder Polyamide Insulation Strip Production Line Plastic Extrusion Machine

Machine Extrude Chain Guide Nylon Runway Guide Rial Guide

- Overview

- Recommended Products

Description:

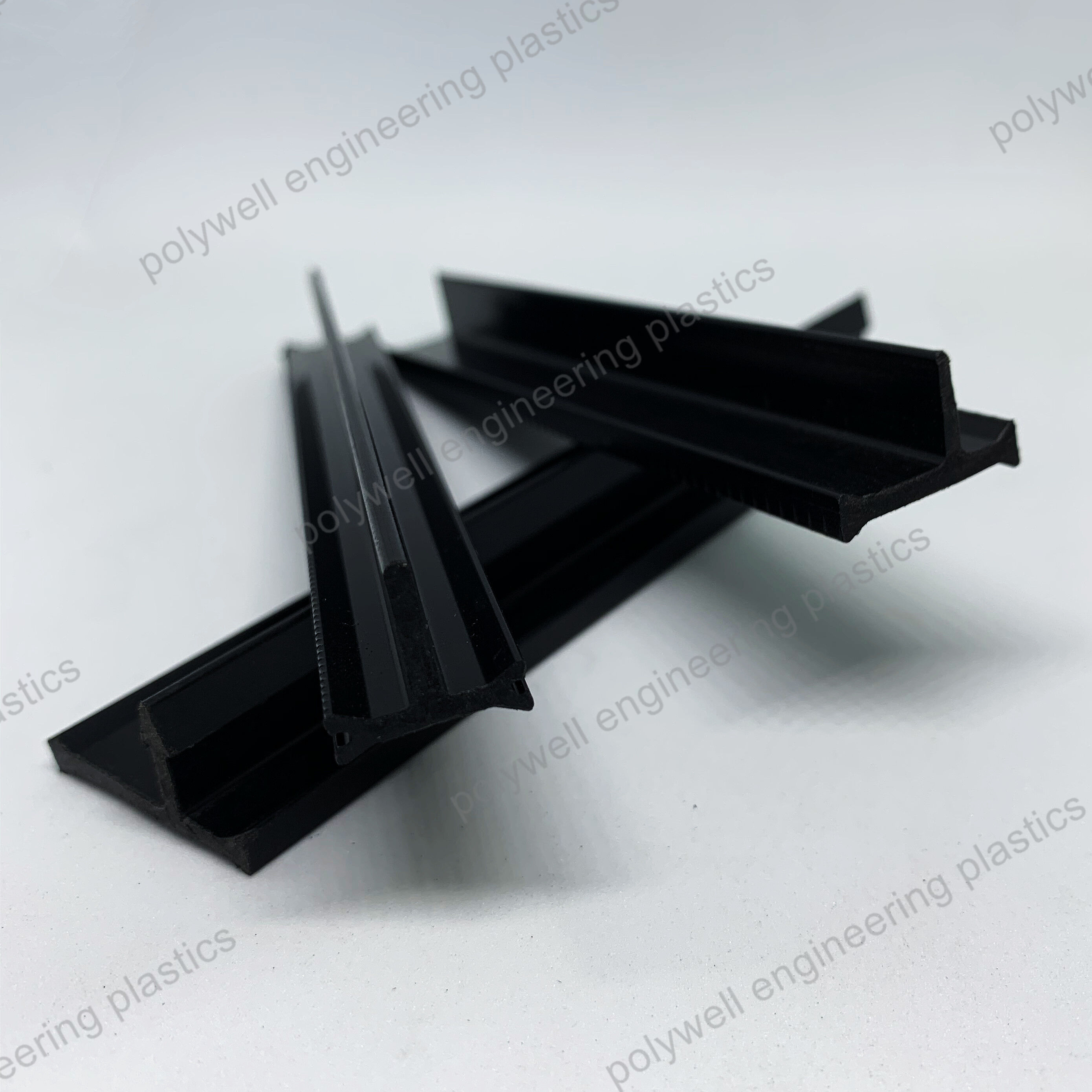

Automatic PA profiles extruding machine is for the production of polyamide thermal break profiles, which used in aluminum windows and doors.

Many customer use thermal break aluminum profile to do windows and doors to keep the heat from being affected by cold air, then make use of energy saving.

Production Speed |

Around 8-14cm/min |

Strip Shape |

All kinds of shape |

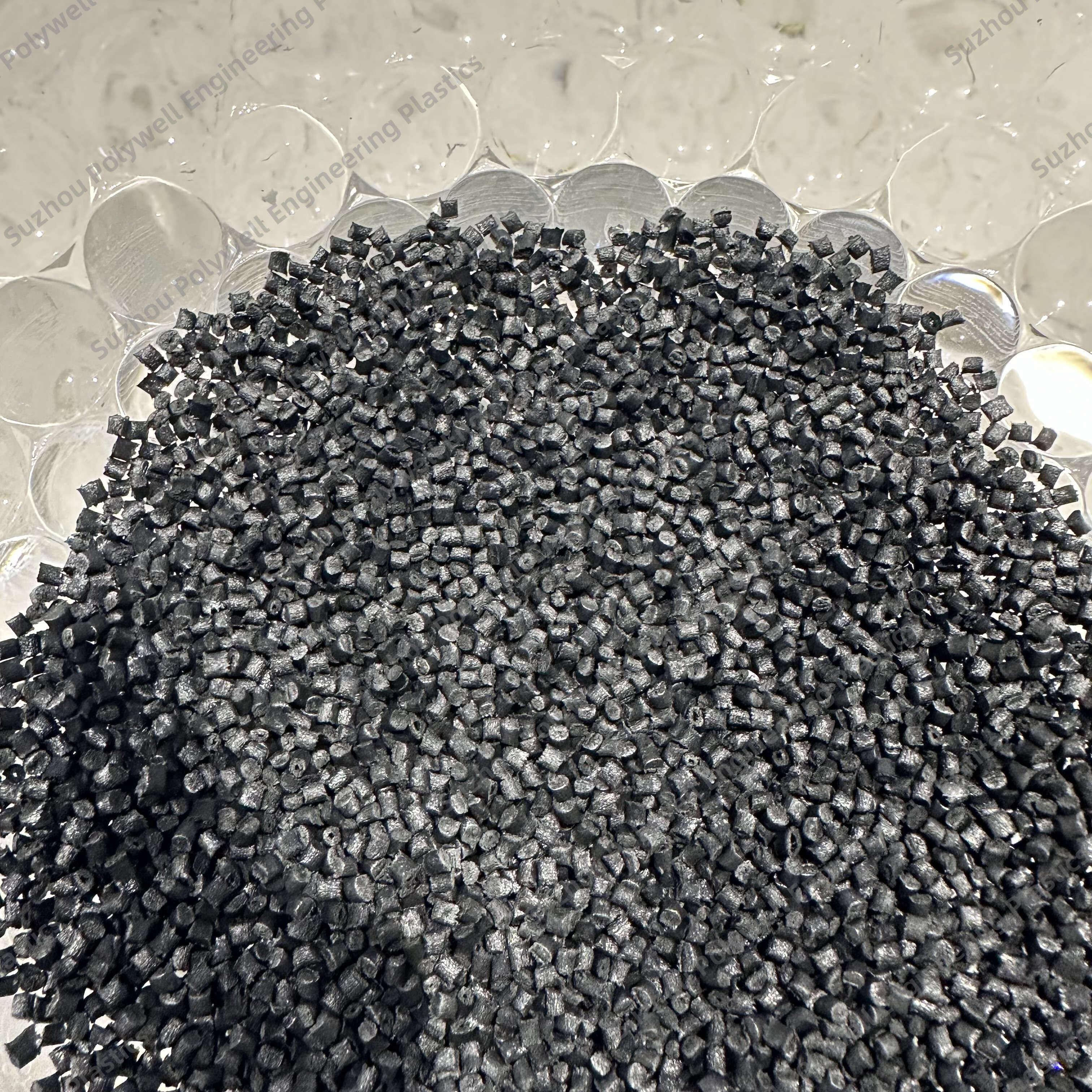

Raw Material |

PA6.6 granules reinforced by 25% glass fiber |

Cooling |

Water cooling |

Usage |

Produce thermal break strip |

Type |

Plastic extrusion machine |

Winding Machine |

Available |

Cutting Machine |

Available |

Worktable |

Available |

FAQ:

Q: What is your MOQ for the polyamide strip extrusion machine?

A: 1 set.

Q: As new player of polyamide strips extrusion, how we learn to use the machine?

A: Polywell will provide paper and videos files to help customer operate the machine. If customer needs, we can also provide on site training service.

Q: Can we customize and buy the raw materials and molds?

A: We can provide every product related to the polyamide thermal break profiles production. Including the raw material, the mold, the cutting machine, the worktable, the winder and so on.

Q: What is the warranty for your machine?

A: For extruder machine, it is one year. We are confident in our products, and pack them well before delivery, so usually you will receive your order in good condition. Any quality issue, we will deal with it immediately.

Q: What is your payment terms?

A: 50% T/T deposit before production, 50% T/T balance before loading.

One to one consulting service.

Experienced senior engineer to discuss technical data, designed drawing.

Perfect arrangement of sea or air transport.

Overseas aftersales service.

Professional engineers team.

Welcomed to visit the factory at any time.

Choosing Polywell means choosing the certainty of a reliable partner, able to team up and offer daily support. We are where you need us, whenever you need us.

EN

EN