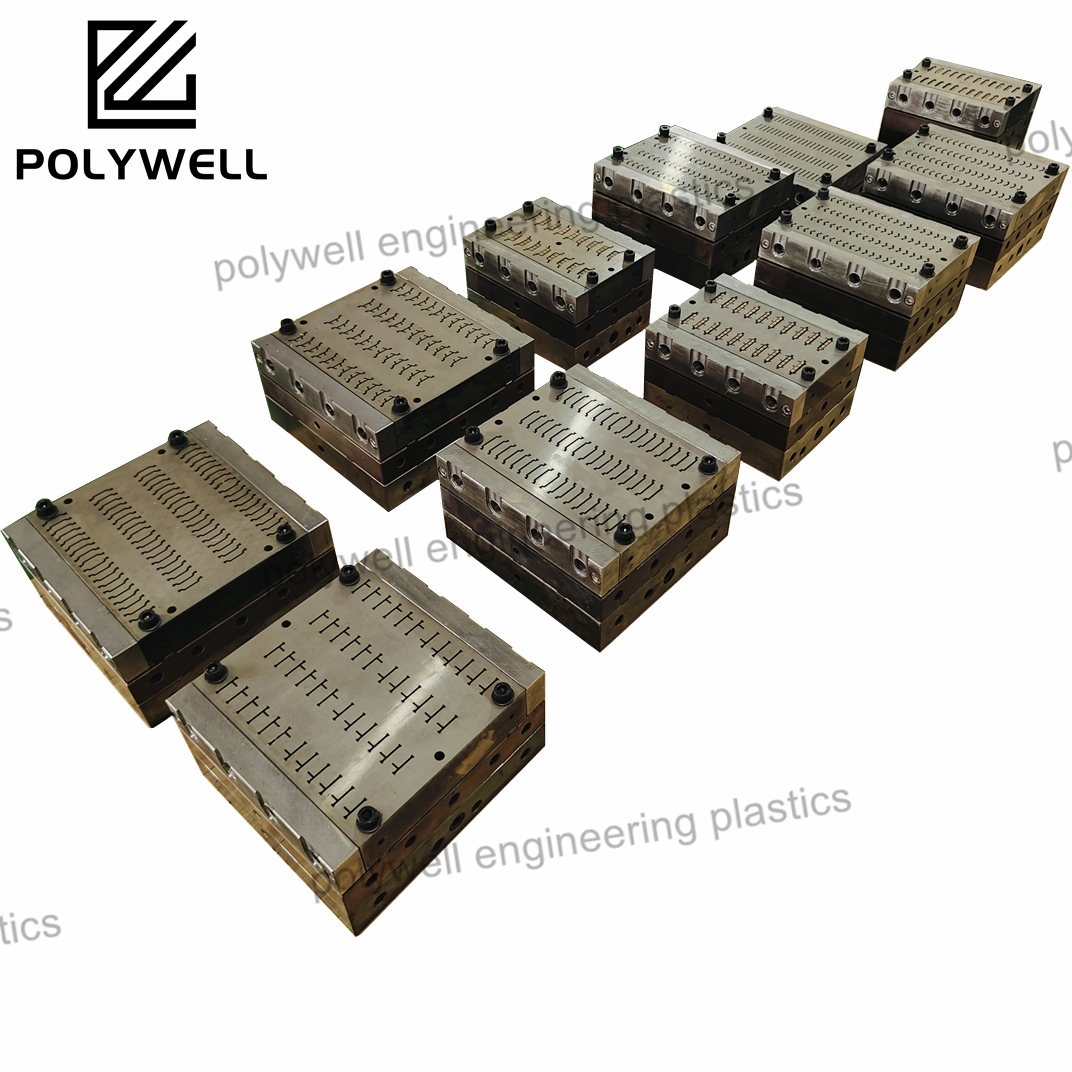

The need to come up with the energy saving construction material has brought about advancements in the thermal break technology. POLYWELL is known in the extrusion molding industry for the production of high quality thermal break strips, thanks to the exquisite design of the extrusion molds used.

What is an Extrusion Mold and Why is it of Importance? An extrusion mold is used for shaping materials into a continuous profile through the extrusion process. In thermal break strips, the role of extrusion mold is to make sure that the cross-sectional dimensions and properties of the thermal break strip do not vary allowing for enhanced insulation. All these help in making sure that the most important quality of the ensemble – its capability of heat insulation between window and door parts – is reached.

How POLYWELL’s Extrusion Molds Work The goal of POLYWELL’s extrusion molds is to make the thermal break strips as accurately as possible while at the same time not using excessive amounts of raw materials. To start, a thermoplastic or rubber material is heat until it becomes soft enough. Next, the material is pushed into the mold which shapes it into strips when the strips are cooled and cut for installation.

Base Molds: The thermal break strip base molds produced by POLYWELL were created so that every single piece matches perfectly into every single space between window and door frames.

Injection Molds: These types of a mold are specifically tailored for adding different functionalities onto the strips e.g. enhanced insulation, color, or texture by injecting different materials into the mold.

Cold Molds: Cold Molds are used to create materials that cannot be set at room temperature and specialized products to meet their insulation demands.

Why POLYWELL’s Extrusion Molds are the Perfect Fit in the Manufacturing of Thermal Break Strips

Precision: The thermal break strips extruded using each of the extrusion mold is designed with a perfect size and each product created is expected to meet the desired standards for thermal insulation and energy reduction.

Customizability: All molds provided by POLYWELL are designed for varying requirements of the clients in the manufacturing of different types of thermal break strips, providing clients with options to select the mold that best suits their requirements.

Efficiency: The use of extrusion molding technology leads to reduced employment of materials which lowers the costs involved in the production process and is more environmentally friendly.

The growth of the construction industry can be attributed to POLYWELL’s intricate extrusion mold designs which in turn are key in the production of thermal break strips. POLYWELL aims at satisfying its clientele by providing them the best products available in the market with regard to energy efficiency of the structures. POLYWELL is the right answer, whether it is base, injection, or cold molds that you are looking for.