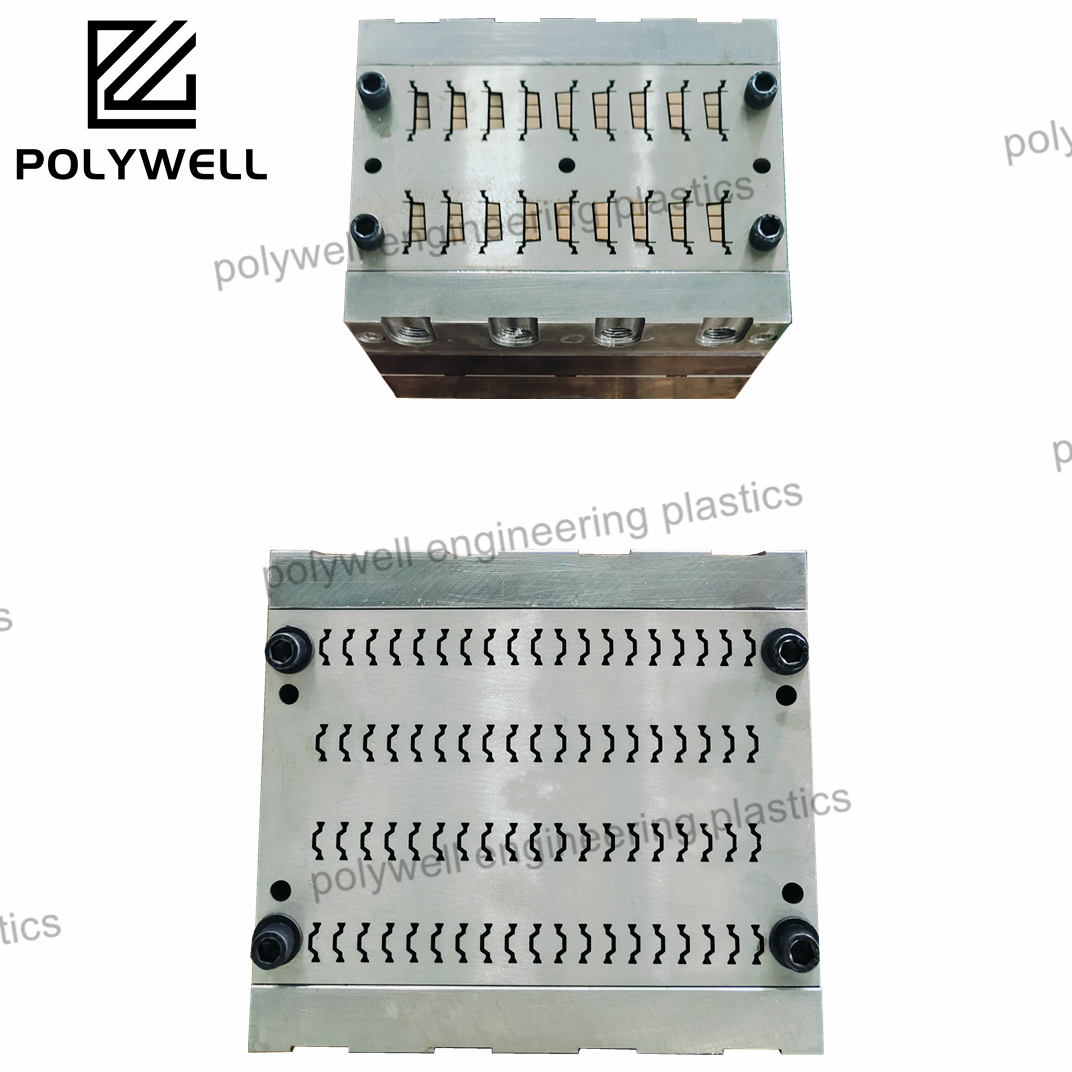

The role played by the extrusion mold is significant during the manufacturing of thermal break profiles. POLYWELL’s extrusion molds are intended to solve the difficulties faced while manufacturing insulated strips made of PA66. Therefore, it comes to no surprise that POLYWELL molds are the most preferred molds among manufacturers across the globe.

Customized Solutions for PA66 Materials

Thermal insulation strips manufactured using PA66 have high shrinkage rate. As such, these strips must be manufactured with good dimensional accuracy. As such, POLYWELL’s molds have been designed using advanced technologies to cater to this shrinkage and allow the final product to be within tolerances.

Experience in Proportional Scaling

Choosing the proper scaling ratio when manufacturing cold molds is no simple task. It takes extensive experience. With POLYWELL however, engineers will have the appropriate experience in sequential re molding and therefore will use a specific ‘know how’ to get the ideal ratio so the thermal break strips will come out accurate.

Dedication to New Ideas

Research and development is the key to advancement, and at POLYWELL, we invest significantly in extrusion mold design improvements. With that seamless strategy, customers are getting finished molds that are refined enough for effective and fast use thereby minimizing material wastage and production idleness.

Why Choose POLYWELL?

That is simple:

Accuracy: All molds are designed to provide the user with the necessary geometric conformance along with a proper surface.

Tailoring: All molds are designed to cater for the individual client’s requirements.

Reliability: Our control regimes are such that the moulds work without any defects.

Support: We offer end-to-end assistance including aiding the clients with designing and servicing them after the sale has been completed.

Excellence and innovative approach is what differentiates POLYWELL from the rest of the players in the extrusion mould business. Our clients who buy our moulds can make the PA66 thermal insulation strips with ease and surety. Reach out to POLYWELL now to find out about our tailored mold solutions.