The energy efficiency and longevity of modern architectural designs depend significantly on the thermal break strip. POLYWELL focuses on the production of high-class extrusion molds which allow clients to fabricate compliant and correctly sized thermal break strips. These strips which are used in windows, doors and curtain walls require high precision molds to counter raw material shrinkage.

Problems Faced During the Production of Extrusion Moulds

Thermal break strips are manufactured in a way where raw slumps are used, behind this is shrinkage which is both natural and a key component of the end product specifications. POLYWELL makes it a point that this problem is sorted out by not only relying on measurements provided by the buyers but also taking into consideration various aspects affecting the strip manufacturing.

Behavior of Each Material: A Crucial Aspects In Thermal Breaks Strips Production

Each material used for the thermal break strip has a defined shrinkage characteristic which can be detrimental to the mold during the manufacturing process if overlooked. POLYWELL has developed in its arsenal enough research and experience to provide specific adjustment ratios for accurate gaps.

Considering Cold Mold Temperature: Adjustments For Proper Mould Construction

Cold processing data for molds should be enlarged to accounts for shrinkage. Not getting the dimensions in shape could affect the final quality of the section focus on thermal break straps which is of utmost importance as it requires a certain level of experience.

Extrusion Molds for Thermal Break Strips: What You Should Know

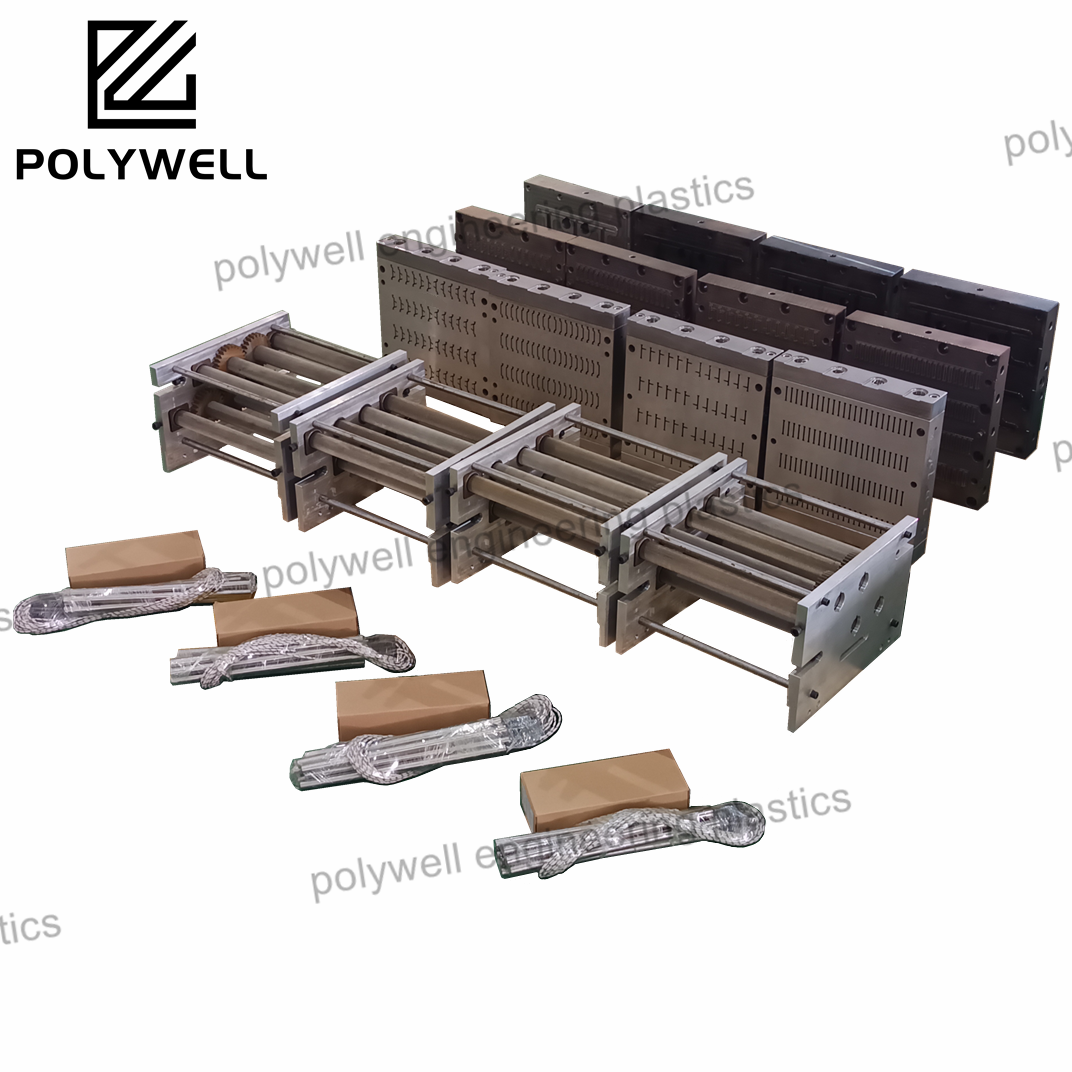

POLYWELL is an innovative company that produces thermal break strips and offers three primary types of molds. They are;

1. Base Molds: These are very crucial in determining the quality of the strips since they form its base. Care has to be taken in the molds calibration to ensure that defects do not occur during the extrusion process.

2. Injection Molds: These injection molds serve the purpose of reproducing intricate designs and patterns incase an order requires so. Such molds will be used in complex designs and patterns which in turn means that they will be of much higher accuracy than cheap PRC made extrusion.

3. Composite Molds: Such molds are integrated as a mix of both base and injection molds due to special requirements that the customers may need to have.

Why It Matters That You Have Experience in Mold Manufacturing

Extrusion molds design is as artistic as it is investigative, the ability to be able to make the other detested adjustment of adding or reducing a materials ratio has to come from years of physical work such as the type POLYWELL is known for. There hand work is supplemented with technology and knowledge of the industry to meet the required standards.