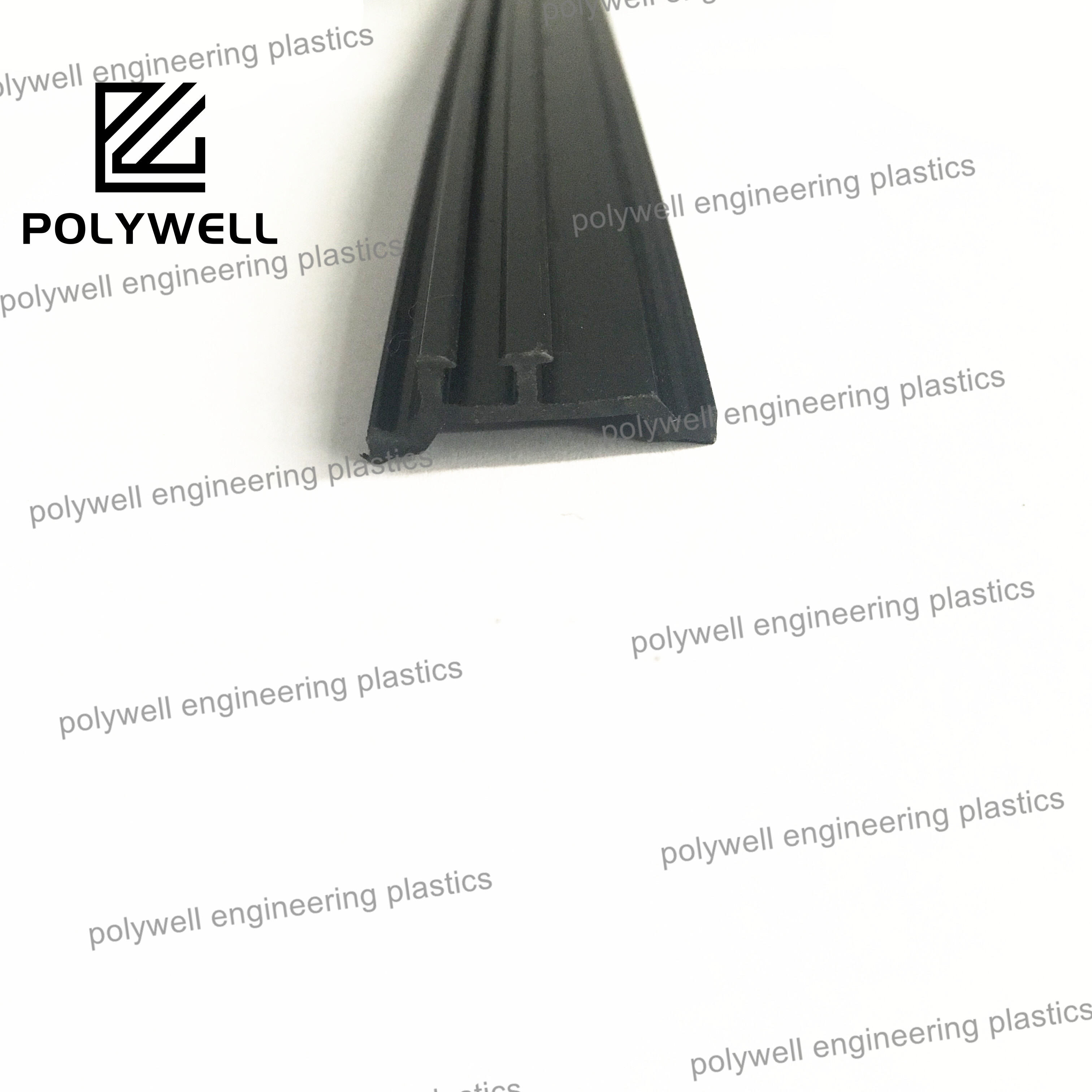

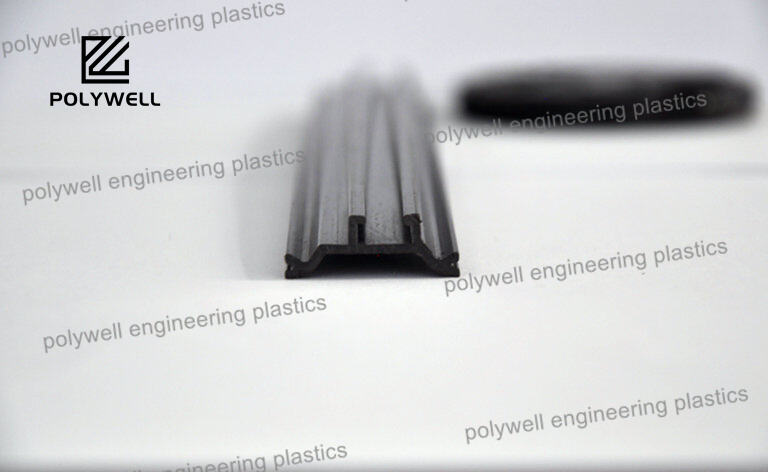

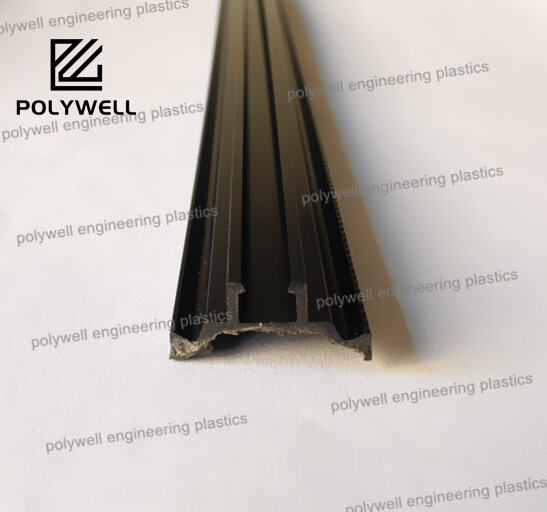

A PA profile, referring to an extruded profile manufactured from Polyamide (Nylon), represents a critical category of engineering components valued for their exceptional mechanical strength, wear resistance, and thermal stability. While Polyamide 6 and PA 66 are the most prevalent base materials, these profiles are rarely used in their pure, unreinforced form for structural applications due to their inherent hygroscopicity and tendency to dimensional change. Instead, they are typically compounded with reinforcing agents, most commonly glass fibers, to create grades like PA66 GF30, which significantly enhance tensile strength, stiffness, and heat deflection temperature. The production of PA profiles is primarily achieved through a process of plastic extrusion, where the thermoplastic compound is heated to a molten state and forced through a die to create a continuous shape with a constant cross-section. This process allows for the manufacture of highly complex geometries, including strips, rods, tubes, and custom-designed channels specifically for applications such as thermal break strips in aluminum windows and doors. The key properties that make PA profiles suitable for such demanding roles include a favorable balance of a relatively low thermal conductivity (around 0.3 W/m·K for glass-filled grades) and high mechanical load-bearing capacity. They exhibit excellent resistance to abrasion, chemicals like oils and solvents, and fatigue, ensuring long-term performance in dynamic applications. However, careful consideration must be given to their moisture absorption; pre-drying before processing is mandatory, and in service, the initial dimensional change upon moisture equilibrium must be accounted for in the design tolerances. Beyond construction, PA profiles are indispensable in automotive industries for guide rails and seals, in machinery for wear strips and gears, and in consumer goods. Their versatility, combined with the ability to be precision-extruded, makes them a fundamental building block in modern engineering, offering a polymer-based solution where metal is unsuitable due to corrosion, weight, or thermal bridging concerns.