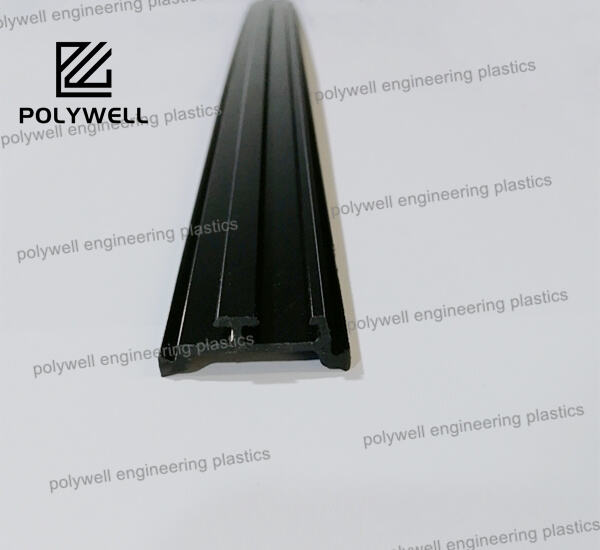

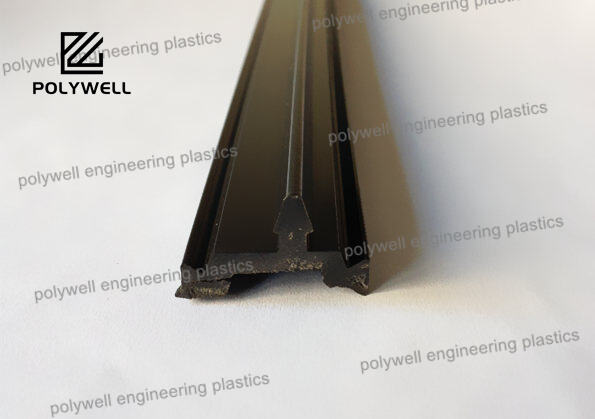

An insulation break, often used synonymously with 'thermal break,' is a fundamental concept in building science and thermal engineering referring to the intentional introduction of a material with low thermal conductivity into a assembly to disrupt an otherwise continuous path of high thermal conductivity. It is the strategic 'break' in the insulation layer that prevents thermal bridging. The term can describe both the conceptual design principle and the physical component itself. In a building context, an insulation break is crucial at all junctions where the primary insulation layer is interrupted, such as where a concrete slab connects to an exterior wall, around window and door frames, and at structural penetrations. The effectiveness of an insulation break is determined by the thermal properties of the break material (its k-value), its geometry (width and depth), and its continuity. For example, in a metal window frame, the insulation break is the polyamide strip that separates the inner and outer aluminum sections. In a more general sense, any gap or compromise in the insulation layer, even if unintentional, can be described as a break in the insulation, which highlights the importance of continuity for overall performance. The goal of deliberate insulation break design is to create a continuous thermal barrier around the building envelope, maximizing the effective R-value of the entire assembly. This principle is applied not only in construction but also in electronics (e.g., thermal breaks in heat sinks), industrial design, and appliance manufacturing to manage heat flow, improve efficiency, prevent condensation, and ensure user safety and comfort. Properly detailing and executing insulation breaks is a critical skill for designers and builders aiming to achieve high-performance, energy-efficient, and durable structures.