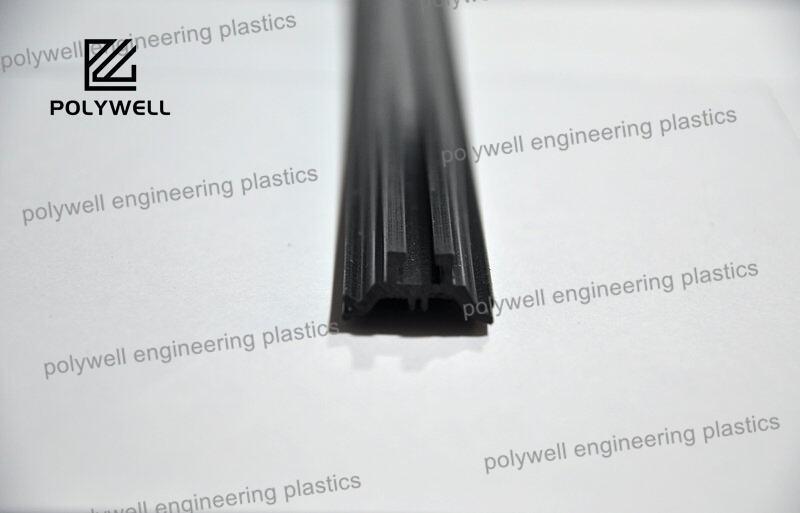

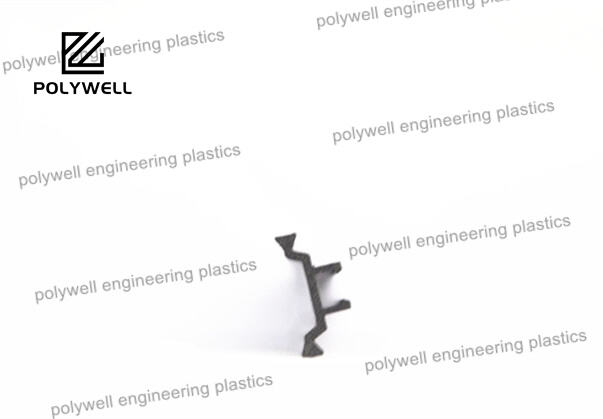

A thermal break is a fundamental principle in building physics and an engineered component designed to interrupt the path of heat flow through a material with high thermal conductivity. In construction, it specifically addresses the problem of thermal bridging, where elements like aluminum or steel frames, concrete slabs, or structural brackets create a shortcut for heat to bypass the insulation layer, leading to significant energy loss, condensation, mold growth, and occupant discomfort. The thermal break itself is a section of material with low thermal conductivity that is inserted between the two conductive parts. In the context of aluminum fenestration, this is typically a rigid strip of glass-fiber reinforced polyamide (PA66 GF25/30) that is mechanically locked and sometimes bonded within the aluminum profile, separating the interior and exterior sections. The efficacy of a thermal break is measured by its thermal resistance and its impact on the overall U-value and linear thermal transmittance (Psi-value) of the assembly. However, a functional thermal break must also possess sufficient mechanical strength to transfer structural loads (such as wind pressure and operating forces) between the separated conductive parts, resist creep under constant load, and maintain its properties over a wide temperature range and throughout the lifespan of the building. The implementation of thermal breaks is no longer an optional upgrade but a mandatory feature in energy-efficient building design, required by building codes worldwide and essential for achieving green building certifications. It represents a critical synthesis of material science and architectural engineering to enhance building performance, durability, and sustainability.