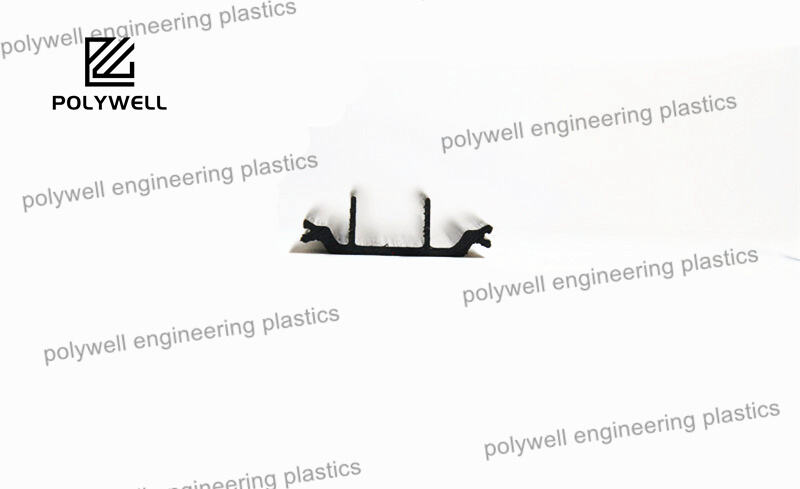

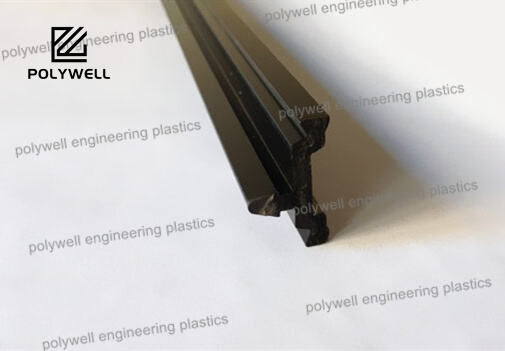

Thermobreak insulation, often a proprietary or brand-specific term for a thermal break system, refers to the integrated assembly and material science behind creating a high-performance thermal barrier within conductive building components. It encompasses more than just the insulating strip; it includes the entire engineered solution designed to prevent thermal bridging in applications like aluminum windows, doors, curtain walls, and structural connections. The core of thermobreak insulation is typically a rigid, structural polymer, with glass-fiber reinforced polyamide 66 (PA66 GF30) being the industry benchmark due to its optimal balance of a low k-value (~0.3 W/m·K) and high mechanical strength. This material is precision-engineered into a profile that is then permanently integrated into the metal assembly, either via the "pour and debridge" process for new extrusions or as a mechanically locked strip in retrofit systems. The performance of thermobreak insulation is quantified by its ability to reduce the linear thermal transmittance (Psi-value) at the juncture, directly contributing to a lower overall U-value for the building envelope. Its effectiveness is contingent upon the material's long-term stability, including resistance to creep under the compressive load of the metal, fatigue from thermal cycling, and degradation from environmental exposure. A high-quality thermobreak insulation system will have undergone rigorous testing per standards like EN 14024 to certify its mechanical and thermal properties. By implementing such a system, builders and architects can achieve significant energy savings, eliminate cold bridges that lead to condensation and mold, improve occupant comfort, and meet the demands of modern energy codes and sustainable building programs, making it an indispensable technology for contemporary construction.