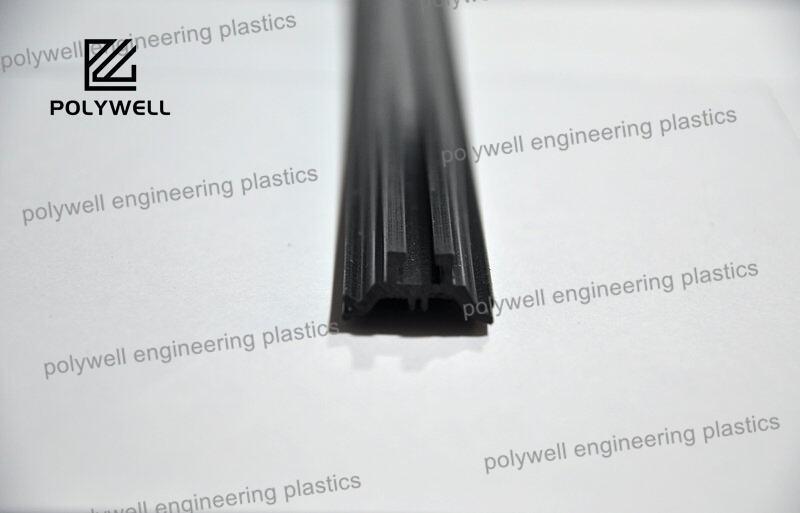

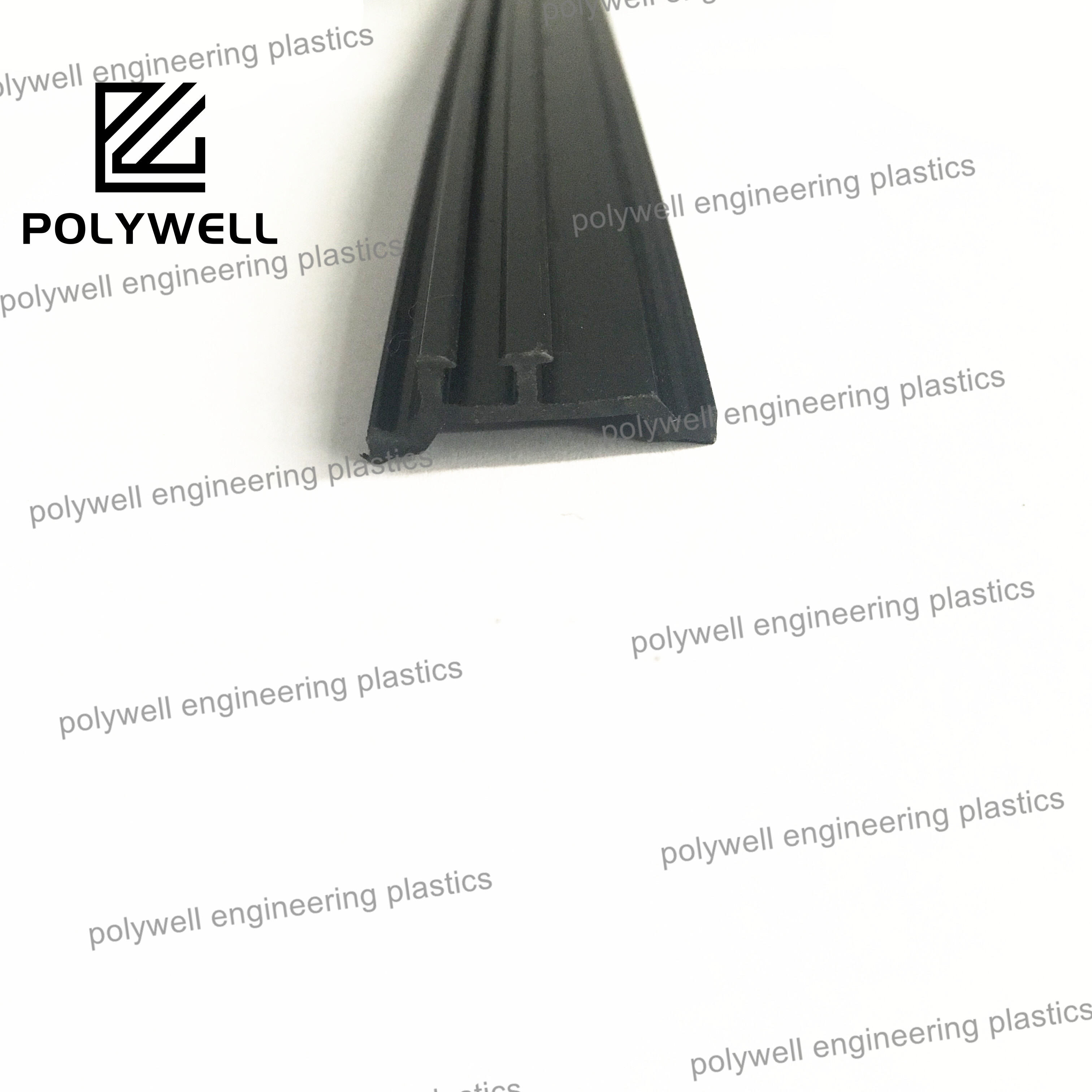

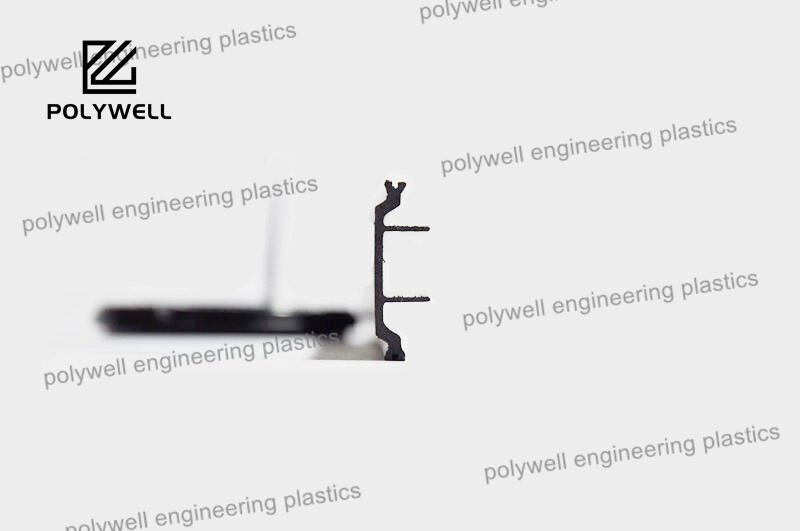

Thermal break aluminum profiles are extruded aluminum sections engineered with an integrated thermal barrier, making them a cornerstone of energy-efficient fenestration and curtain wall systems. Standard aluminum, while strong and durable, is an excellent thermal conductor (~160 W/m·K), making it a significant thermal bridge if it spans from a building's interior to exterior. Thermal break technology solves this by separating the interior and exterior aluminum parts with a structurally sound polymer strip, typically made from polyamide 66 reinforced with glass fibers (25-30%). This strip is mechanically locked into the aluminum extrusions through a process known as "pour and de-bridge," where the aluminum is first extruded with a channel, the thermal polymer is poured in, and then the connecting aluminum web is removed, or via a "roll-in" method for certain systems. The resulting profile exhibits a dramatically reduced U-value, as the conductive path is broken by the low-conductivity polymer (~0.3 W/m·K). These profiles must be rigorously engineered to withstand structural loads, including wind pressure, water infiltration, and operating forces for windows and doors, while maintaining the integrity of the thermal barrier. The polyamide core provides sufficient shear strength to transfer these loads between the inner and outer aluminum halves. The use of these profiles is essential for meeting modern building energy codes, preventing condensation on interior frames, improving occupant comfort, and achieving sustainability certifications. They are ubiquitous in commercial and high-performance residential construction globally, representing a critical fusion of material science and architectural engineering to overcome the inherent thermal limitations of metal framing.