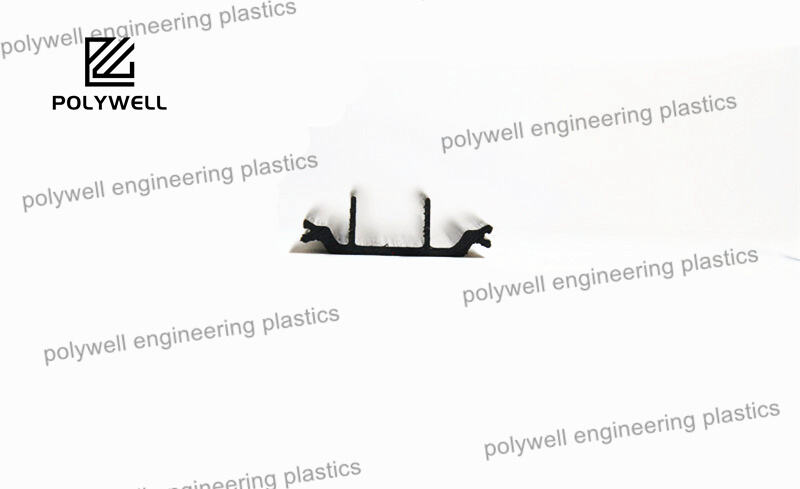

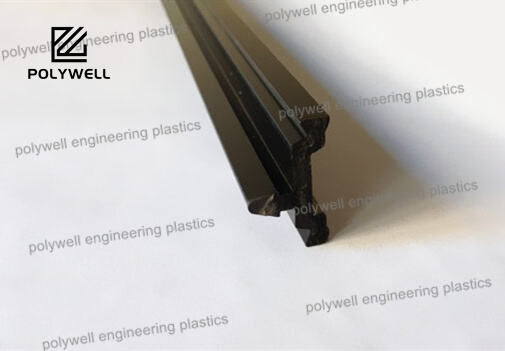

A structural thermal break material is a high-performance component designed to simultaneously provide thermal insulation and transfer significant structural loads between building elements, effectively eliminating thermal bridges in load-bearing connections. Unlike standard insulation, these materials are engineered to possess high compressive strength, high shear strength, and low creep under sustained load, all while maintaining a low thermal conductivity. Common applications include insulating connections between concrete balconies and floor slabs, steel cantilevered beams, and parapet supports—all classic points of major heat loss and potential condensation. The materials are typically composite polymers, with polyamide (PA66) reinforced with high percentages (e.g., 30-40%) of glass fiber being a prevalent choice due to its optimal balance of mechanical properties (compressive strength >100 MPa, shear strength >40 MPa) and thermal resistance (k-value ~0.3 W/m·K). Other systems might use dense, fiber-reinforced polymer concrete or advanced epoxy composites. The design involves careful analysis of the loads (dead, live, wind, seismic) and the thermal performance (Psi-value) to select the appropriate material and thickness. Installation is critical; the material is precision-cut and placed within the formwork before concrete is poured, or it is bolted between steel members, ensuring full bearing and no point contacts that could bypass the insulation. By using a structural thermal break, the building envelope remains continuous, leading to higher interior surface temperatures, reduced energy loss, eliminated condensation risk, and compliance with energy standards. This technology is fundamental to the design of high-performance, thermally broken building skeletons, allowing architects and engineers to create expressive forms like cantilevered balconies without compromising the thermal integrity of the building enclosure.