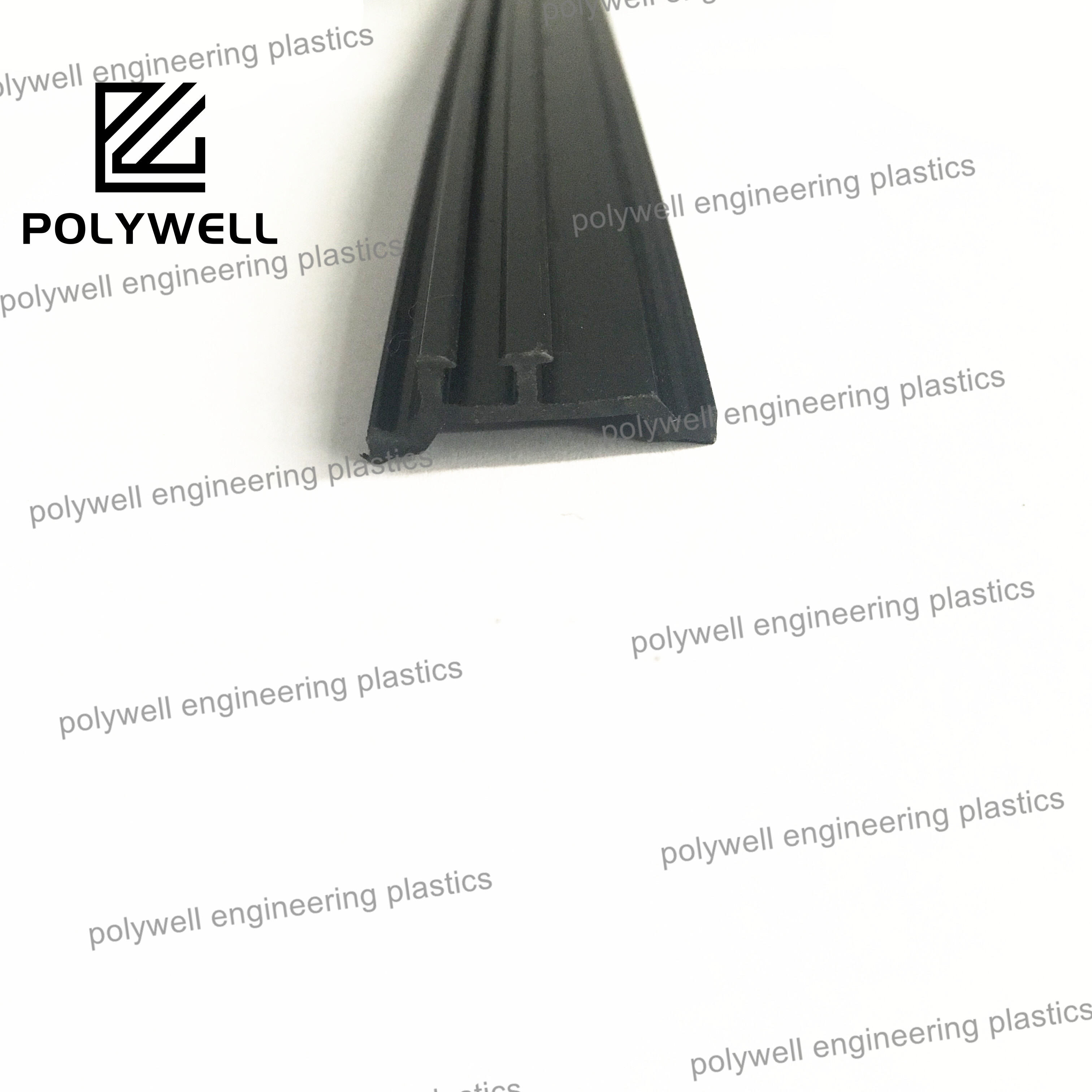

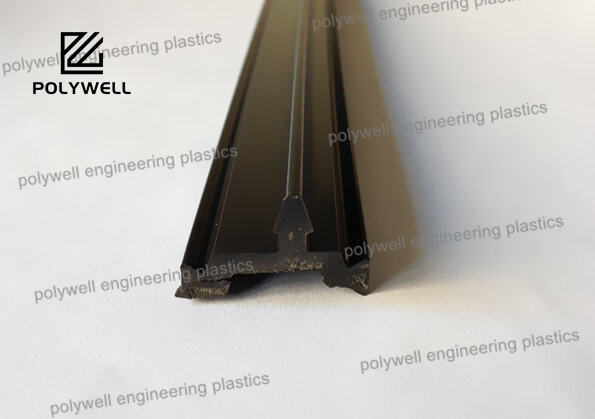

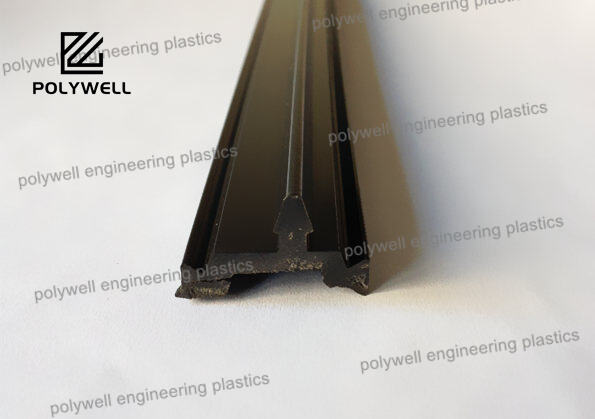

Thermal break material is the substance specifically engineered to provide a barrier of high thermal resistance within an otherwise conductive assembly, fundamentally aimed at mitigating thermal bridging. Its selection is based on a critical balance of properties, where low thermal conductivity must be complemented by sufficient mechanical strength, long-term durability, and processability. While various rigid foams and some thermosets have been used, the industry standard for high-performance applications, particularly in aluminum fenestration and structural thermal breaks, is glass-fiber reinforced polyamide 66 (PA66). This composite material, with glass fiber content typically ranging from 25% to 30%, offers an optimal property set: a thermal conductivity around 0.3 W/m·K, which is orders of magnitude lower than aluminum, combined with high tensile, compressive, and shear strength. This mechanical robustness is non-negotiable, as the material must transfer structural loads between the inner and outer metal sections while resisting creep (cold flow) under constant pressure over decades of service. Furthermore, an effective thermal break material must exhibit excellent thermal stability, with a melting point above 250°C to withstand processing temperatures and a high Heat Deflection Temperature (HDT) to maintain dimensional integrity in real-world conditions. Resistance to environmental factors such as UV radiation (if exposed), moisture, and chemicals like alkalis in concrete or cleaning agents is also essential. The material must be compatible with manufacturing processes like extrusion for strip profiles or casting for the "pour and debridge" method in aluminum windows. Ultimately, the choice of thermal break material directly dictates the energy efficiency, condensation resistance, structural safety, and longevity of the entire assembly, making it a cornerstone of modern sustainable building design and a critical focus of material science in construction.