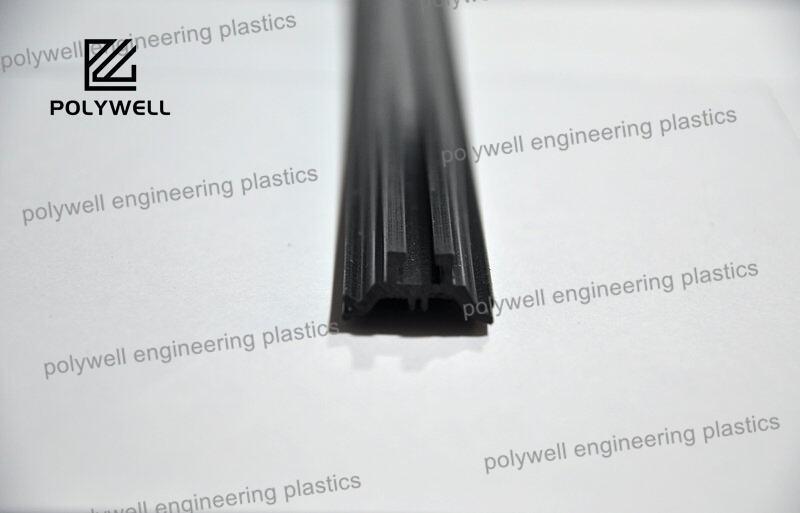

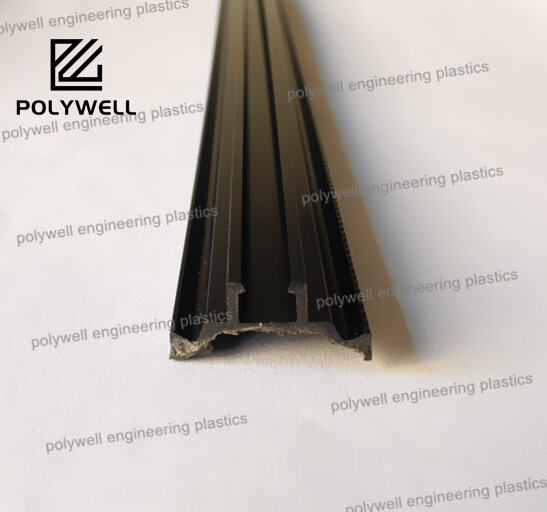

A thermal break profile is a specialized engineered component, typically an extruded polymer section, designed to be integrated into a metal assembly—most commonly aluminum or steel windows, doors, curtain walls, and structural brackets—to drastically reduce heat transfer. It functions as the core insulating element within a thermally broken system, physically separating the interior and exterior metal parts to create a barrier of low thermal conductivity. The most advanced and widely specified thermal break profiles are manufactured from glass-fiber reinforced polyamide 66 (PA66 GF25 or GF30), a material chosen for its optimal combination of low thermal conductivity (approximately 0.28-0.32 W/m·K) and high mechanical strength, including compressive and shear strength, to withstand the stresses imposed by the metal cladding and structural loads. The profile's geometry is critically engineered not just for thermal performance but also for its mechanical interlock with the metal. In aluminum systems, this is often achieved through the "pour and debridge" process, where the polyamide is cast into a channel in the aluminum extrusion and then a connecting aluminum web is removed, or via a "roll-in" method where the metal is mechanically crimped over the polymer profile. The performance of a thermal break profile is quantified by its ability to lower the linear thermal transmittance (Psi-value) of the entire assembly, directly contributing to a reduced U-value for the window or door. Beyond energy efficiency, it prevents condensation on interior frames, enhances occupant comfort by maintaining warmer surface temperatures, and is essential for meeting stringent international building codes and sustainability certifications like Passive House, LEED, and BREEAM. The design, material selection, and manufacturing precision of the thermal break profile are therefore paramount to the success of any high-performance fenestration or building envelope system.