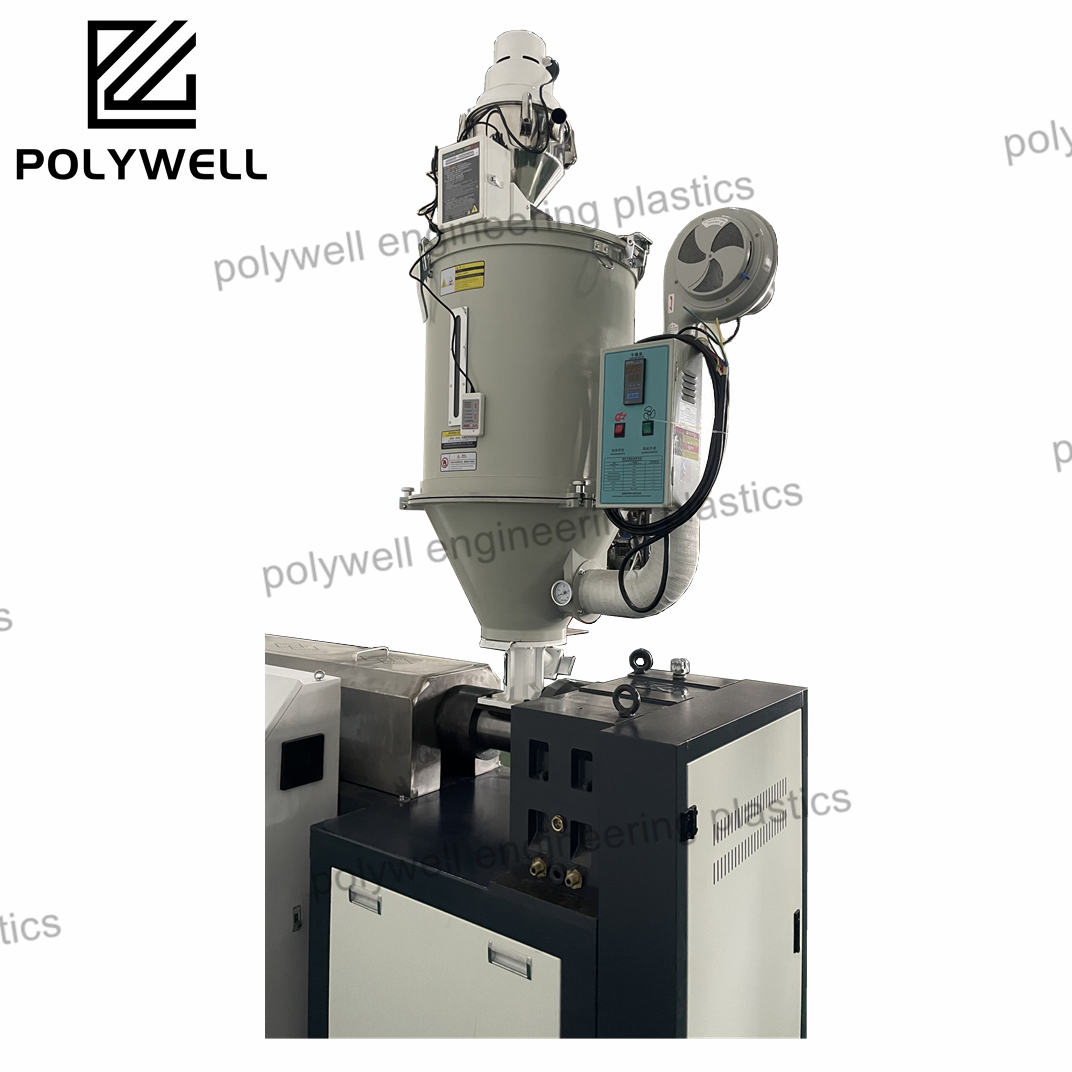

The single screw extruder is one of the essential equipment in production of thermal break strips. It is a technology which has proven to be accurate and flexible and assists the manufacturers and the procurement personnel to achieve desired results. POLYWELL has developed new designs of extruders which are fabricated for efficiency and also takes into account other aspects of the industry.

Key Advantages of the Single Screw Extruder

Simple Operation: A simplified structure ensures operator’s and maintenance staff’s performance is good which can be beneficial in a busy production centre.

Cost-Effectiveness: The design’s efficient energy consumption and the adaptable structure reduces the amount of raw materials wasted during the extrusion process.

High Compatibility: It is compatible with a wide range of materials, especially polyamide, which is the most common material used in thermal break strips.

Custom Solutions by POLYWELL

POLYWELL manufactures single screw extruders which are customized to suit specific production requirements. By providing customers with different configurations of the barrel, the screw and the die system, users are able to enhance their production efficiency.

Applications in the Thermal Break Strip Industry

Thermal break strips are important in the increasing the energy efficiency of the buildings . Archtectural forms become more and more rigid and so there is a tendency to use single screw extruder to complete the extrusion as it aids in achieving accurate geometry of the profile.

The needs of the manufacturers and procurement team are continuously evolving, hence POLYWELL’s single screw extruders are designed for flexibility and effectiveness. POLYWELL’s Solutions ensure the best results in production processes such as that of thermal break strip.