Energy efficiency is an important criterion in modern construction, and building design should ideally take this into consideration. One of the ways to achieve this is through the use of thermal break strips in windows and doors. POLYWELL’s extrusion moulds are important in this regard as they help in the manufacture of these strips which are insulating and strong.

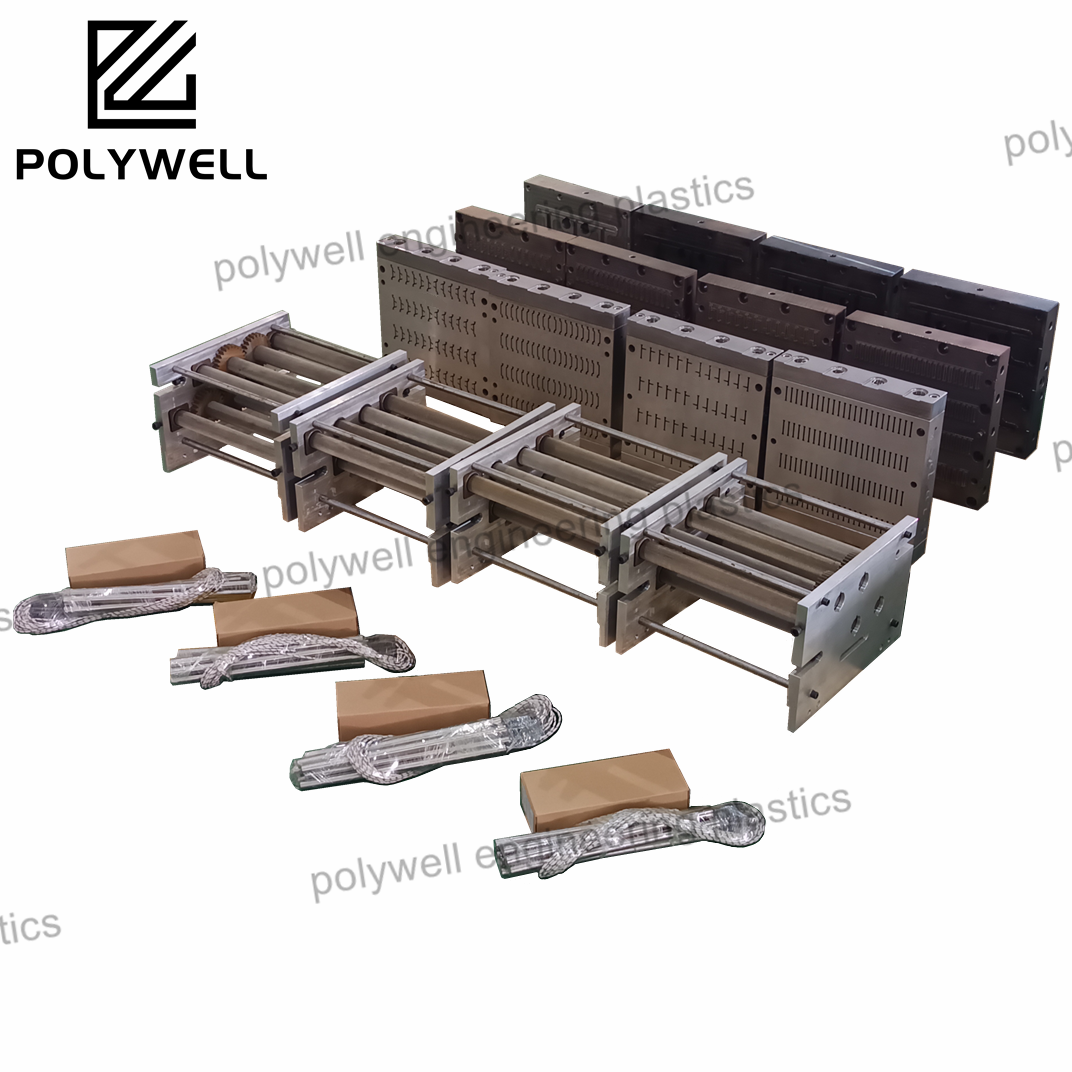

What is An Extrusion Mold? An extrusion mold is a device that is designed to use the extrusion process where a form of material is forced through a mold in order to create shapes on a continuous basis. In the case of thermal break strips which are extrusion moulded, an extrusion mould is used to accentuate the thermal break strip to specific measurement so that the thermal break performs effectively while at the same time ensuring uniform profiles used are suitable for construction purposes.

The Process of Extrusion Molding for Thermal Break Strips As extrusion moulding of thermal break strips commences, the basic or raw material or feedstock which is widely used thermoplastics or rubber or rubber mixtures are fed into an extrusion mould after being heated to a specific temperature. This enables the material to take the shape of the cavity of the mold and after a while extends to form thermal break strips which are then cut into required lengths suitable for windows and doors assembly.

POLYWELL extrusion surameformation molds. Polywell specializes in different kinds of extrusion molding dies including base molds, injection molds, and cold split molds. Each one of the molds is specially designed according to our clients' specific needs, thus enabling the production of high quality thermal break strips which perform excellently in building insulation.

Base Molds Injection Molds: Basemolds are used to form the base surface of the thermal break strips, thus reinforcing the shape cut out which improves performance.

Injection Molds: In this case, additional materials may be injected into the mold with the purpose of adding insulation or color or texture to the strips.

Cold Molds: Cold molds are applicable where only low temperature processing of materials are required. These molds can be formed to withstand different heat factors and hence, give a uniform product.

What are the Pros of Using Extrusion Molding: There are various advantages of extrusion molding over other modes of manufacturing particular of thermal break strips. This are main advantages:

Precision and Consistency: By using the extrusion molds, the end products are consistent as well as uniform and every thermal break strip cut out complies with set standards.

Efficiency: The extrusion process allows for volume production and as such, there would be no in between stoppages and thus, reducing the time taken.

Customization Options: If you are looking to change the dimensions, colors, or material properties of the extrusion molds, POLYWELL has customization options to meet them.

As a company that engineers high-performance thermal break strips, POLYWELL understands the importance of extrusion molds and believes they are lowest in limiting factors. POLYWELL offers something of great value to the market since focus on extrusion engineering does lead to superior products in regards to energy efficiency, indeed in construction scale models. In addition to that, addressing the many construction requirements POLYWELL is arguably a leader in extrusion molded products innovation and quality.