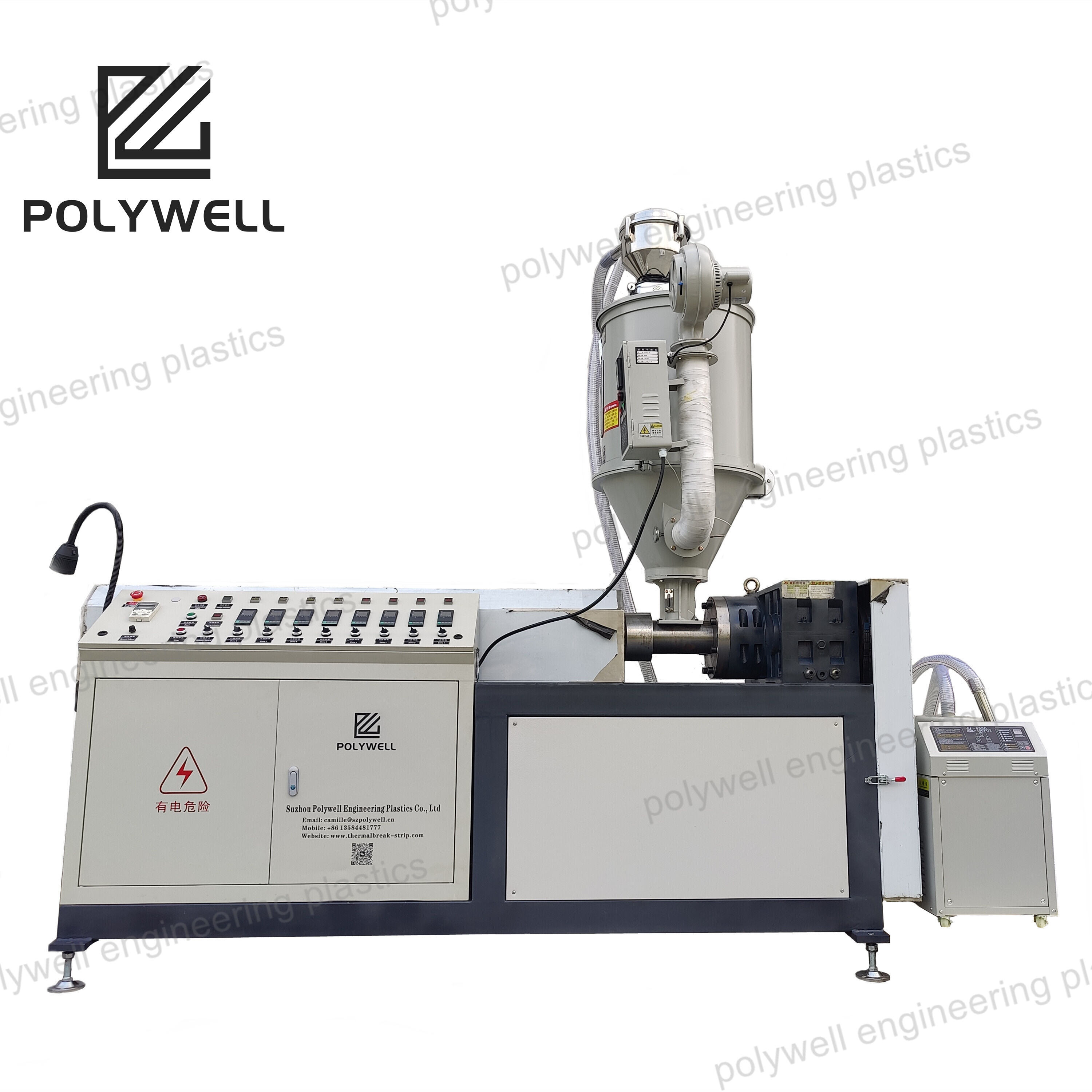

The SJ25 single screw extruder represents a specific model within Chinese extrusion equipment classification, characterized by a 25mm screw diameter and widely used for small-scale production, prototyping, and educational applications. This model typically features a length-to-diameter ratio of 25:1, making it suitable for processing various thermoplastics including polyethylene, polypropylene, ABS, and PVC with output rates generally ranging from 2-8kg/hour depending on material and screw design. Standard construction incorporates a carbon steel barrel with hardened inner surface, integral cooling fans, and cartridge heaters arranged in multiple zones with PID temperature control. Drive systems typically employ AC motors with reduction gearboxes providing screw speeds from 0-100 RPM, though specific ranges vary by manufacturer. The modular design allows for different screw configurations optimized for specific materials, with compression ratios typically between 2.5:1 and 4:1. Common applications include laboratory research, small-batch production of profiles, filaments, or sheets, and educational demonstrations of extrusion principles. While offering cost advantages compared to Western equivalents, technical specifications and construction quality vary significantly among manufacturers, requiring careful evaluation of component sourcing, manufacturing standards, and safety features. Common considerations for operation include adequate cooling capacity for continuous running, potential upgrades to more precise temperature control systems, and compatibility with downstream equipment such as water baths, haul-offs, and pelletizers. The compact footprint and relatively simple operation make these machines accessible for small enterprises and training facilities, though production consistency may require additional process control enhancements. Spare parts availability, technical documentation quality, and manufacturer support vary considerably across suppliers, influencing long-term operational reliability. Despite limitations in precision and advanced features compared to premium laboratory equipment, the SJ25 occupies an important market position providing affordable access to extrusion capability for applications where ultimate process stability and data acquisition are secondary to basic functionality and cost considerations.