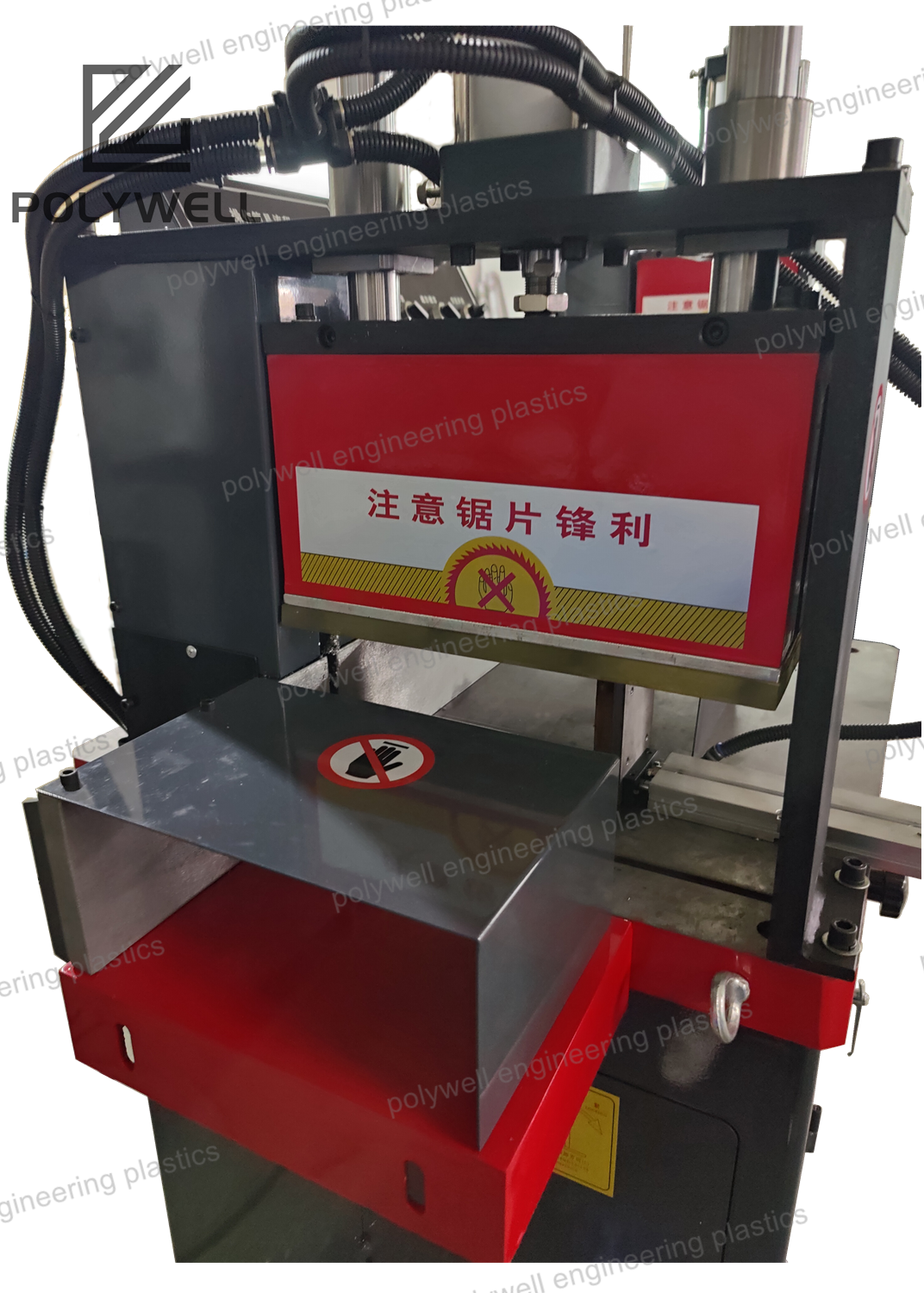

A profile extruder is a complete extrusion system specifically configured for the manufacture of continuous plastic profiles with a constant, often complex, cross-section. These products range from simple vinyl window trims to sophisticated multi-chambered technical profiles used as thermal breaks in aluminum fenestration. The system centers around a single-screw extruder, typically with an L/D ratio between 24:1 and 30:1, chosen for its ability to provide a stable and homogeneous melt. However, the defining components of a profile extruder line are the downstream tools and equipment. The process begins with a custom-manufactured die, precision-engineered to shape the polymer melt into the desired geometry, often accounting for material swell and drawdown. Immediately after the die, the hot, soft profile enters a calibration unit, which is a critical stage where the profile is cooled and its final dimensions are set using vacuum calibration tanks and sizing plates or molds. Following calibration, the profile passes through a cooling bath to solidify it completely. A caterpillar haul-off unit then provides the precise, constant pull force needed to draw the profile from the die without distortion. The line is completed by a flying saw or cutter that severs the profile to the required length. The entire process demands a high degree of synchronization between the extruder output, haul-off speed, and cutter. The expertise in profile extrusion lies not just in the machinery, but in the intricate design of the die and calibration tools, and the precise control of the thermal and mechanical parameters throughout the line to achieve a product with consistent dimensions, mechanical properties, and surface quality.