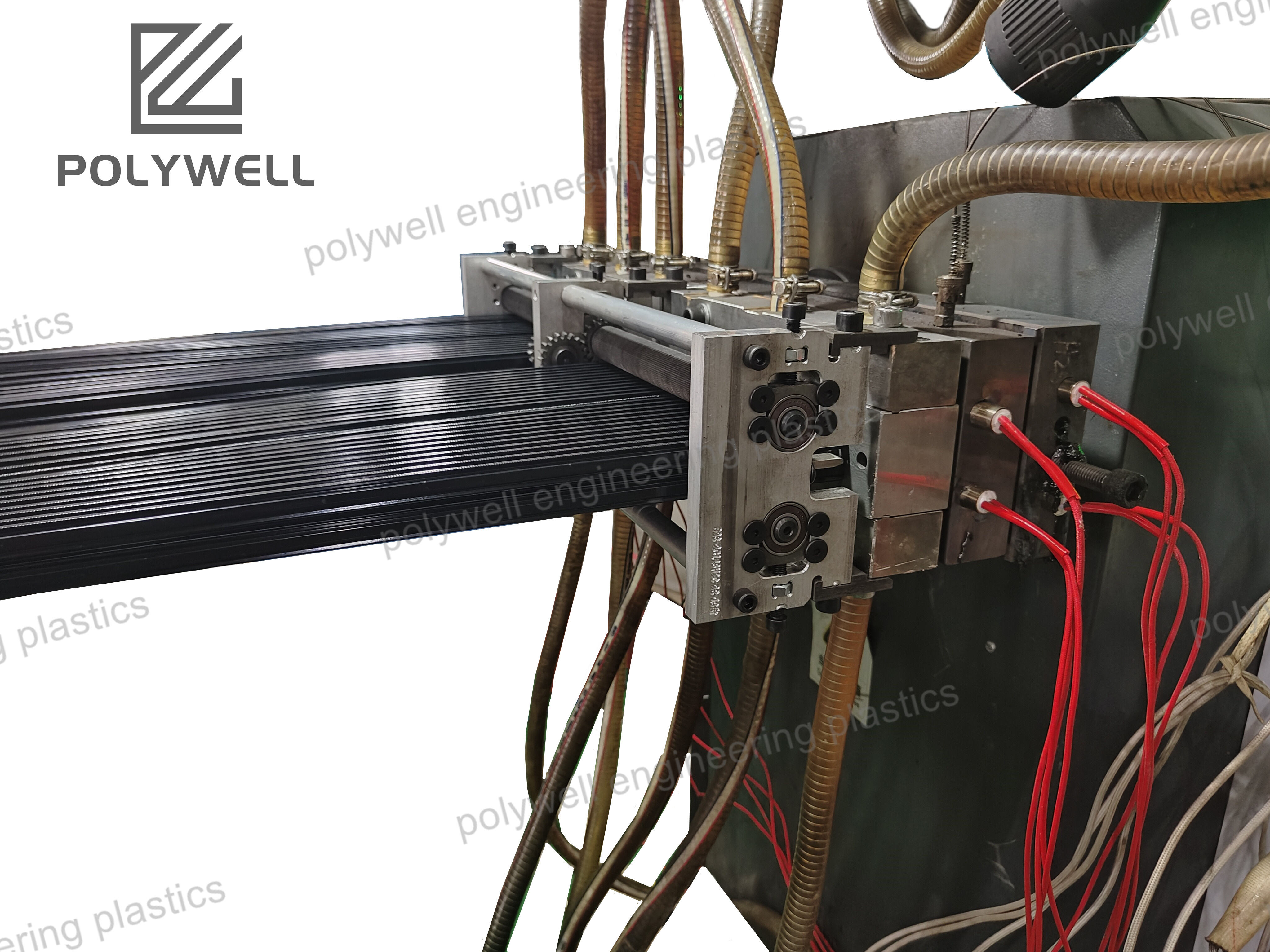

An extruder machine is a complete system for the continuous processing of plastics and other viscous materials, encompassing not only the core extruder unit but also all necessary peripheral equipment to transform raw material into a finished product. At its heart is the extruder proper, comprising a motor, gearbox, screw, and barrel, which works to plasticize and pump the material. However, the term "machine" implies a more integrated setup. This typically begins with upstream components such as material storage silos, vacuum loaders, and dehumidifying dryers, which ensure a consistent and dry feed to the extruder hopper. The molten polymer is then shaped by a die, a critical and custom-made tool that defines the product's cross-sectional geometry. Immediately following the die, the downstream equipment takes over: a calibration device (often using vacuum and water cooling) to solidify the shape, a cooling tank to complete the cooling process, a haul-off or puller to provide tension and draw the product, and finally, a cutter or winder to package the product to length. The entire machine is governed by a centralized control system that synchronizes the speeds of the extruder screw, haul-off, and cutter, while also monitoring and controlling temperatures and pressures throughout the line. The effectiveness of an extruder machine is measured by its overall stability, output rate, and its ability to produce a product with consistent dimensions, appearance, and physical properties, making it a complex and capital-intensive production asset.