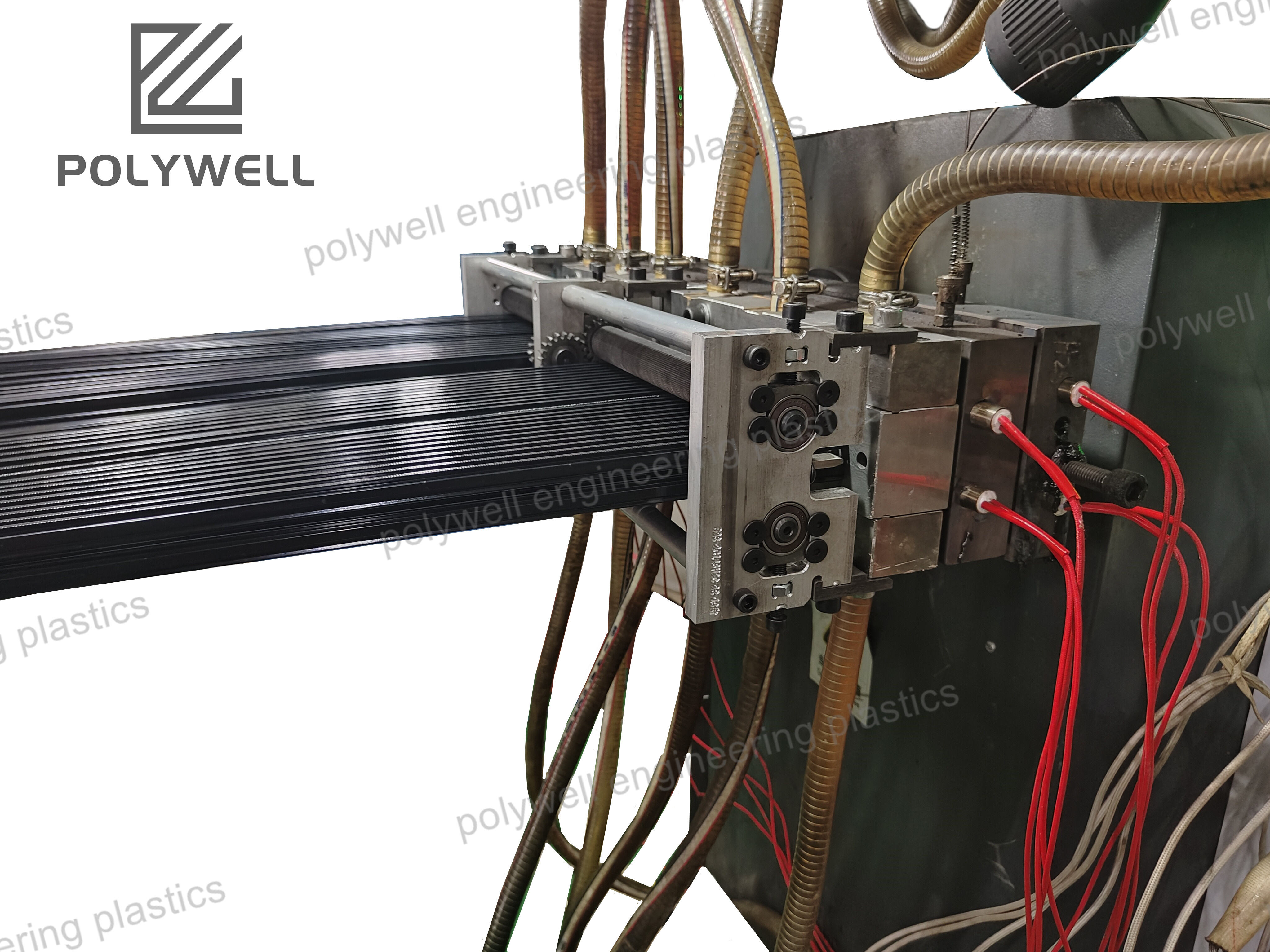

The extruder screw and barrel form the heart of the extrusion process, the crucial components where the physical transformation of plastic from solid to melt occurs under controlled conditions. This duo is a highly engineered system where design and metallurgy are paramount. The screw is a complex shaft with a helical flight that performs the functions of conveying, melting, mixing, and pressurizing the polymer. Its geometry—including flight pitch, channel depth, and compression ratio—is meticulously designed for the specific material being processed. For instance, a screw for PA66 must have a design that accommodates its sharp melting point and high melt temperature, often featuring a longer transition zone. The barrel is a pressure vessel that houses the screw, equipped with multiple heating zones and cooling channels for precise thermal management. To withstand the immense pressure, abrasive fillers, and often corrosive polymer additives, both components are manufactured from high-strength, wear-resistant alloys. Standard surfaces are nitrided for good wear resistance, but for highly abrasive materials like glass-filled nylons, bimetallic barrels with alloy liners (e.g., Xaloy) and screws with hardened flight tips or specialized coatings (e.g., Stellite) are essential for longevity. The clearance between the screw flight and the barrel wall is a critical tolerance; excessive clearance leads to reduced output and poor melt quality, while insufficient clearance risks mechanical seizure. The performance, output rate, and energy efficiency of the entire extruder are dictated by the condition and design of the screw and barrel, making them the most critical wear parts and the focus of continuous technological advancement in extrusion.