In cases of making thermal break strips for construction factors such as insulation and designing extrusions are important. To achieve that POLYWELL provides thermal break strips with the help of extrusion molding optimally designed to achieve both proper thermal break and a strong mold.

With that in mind, thermal breaks have become a vital part of us due to their energy conservation properties. It is largely used in window and door construction which uses POLYWELL’s thermal strips. They are then molder into continuous profiles which get cut down based on the required length. What’s more impressive is the fact that thermal strips create a thermal interferance and prevent any heat flow, especially in doors or windows.

When conducting the extrusion process it is important to follow the steps thoroughly:

Start with Heating: You prepare raw material such as rubber or thermoplastic by heating it making it easy to mold.

Conclude by Using The Mold: Finally take the molten rubber and push it through the Manufacturing Mold enabling the rubber to take shape in accordance to your need.

Cooling and Cutting: After the material is extruded, it is cooled off and cut to the required lengths for construction purposes ready to use.

The Key Benefits of POLYWELL’s Extrusion Molds There are several advantages associated with POLYWELL’s Extrusion molds, the foremost of them being efficiency and accuracy in the production of thermal break strips. Such characteristics that make POLYWELL different from others in the industry include:

High-Quality Molds for Consistent Output: POLYWELL’s molds have been specially built for accuracy which guarantees that the size, the shape and the performance of a particular strip provide an optimum level of satisfaction. Such satisfaction is crucial in the manufacture of thermal breaks which significantly improves energy efficiency.

Durability and Longevity: Our extrusion molds outlast the competition due to robust materials which allow our machines to withstand the rigorous characteristics of the extrusion process while sustaining quality output.

Energy Efficiency: The industrial thermal break developed using POLYWELL’s advanced extrusion molding greatly reduces material waste and energy storage emissions during the fabrication process, making the thermal break strips efficient in insulation, easy and eco friendly to produce.

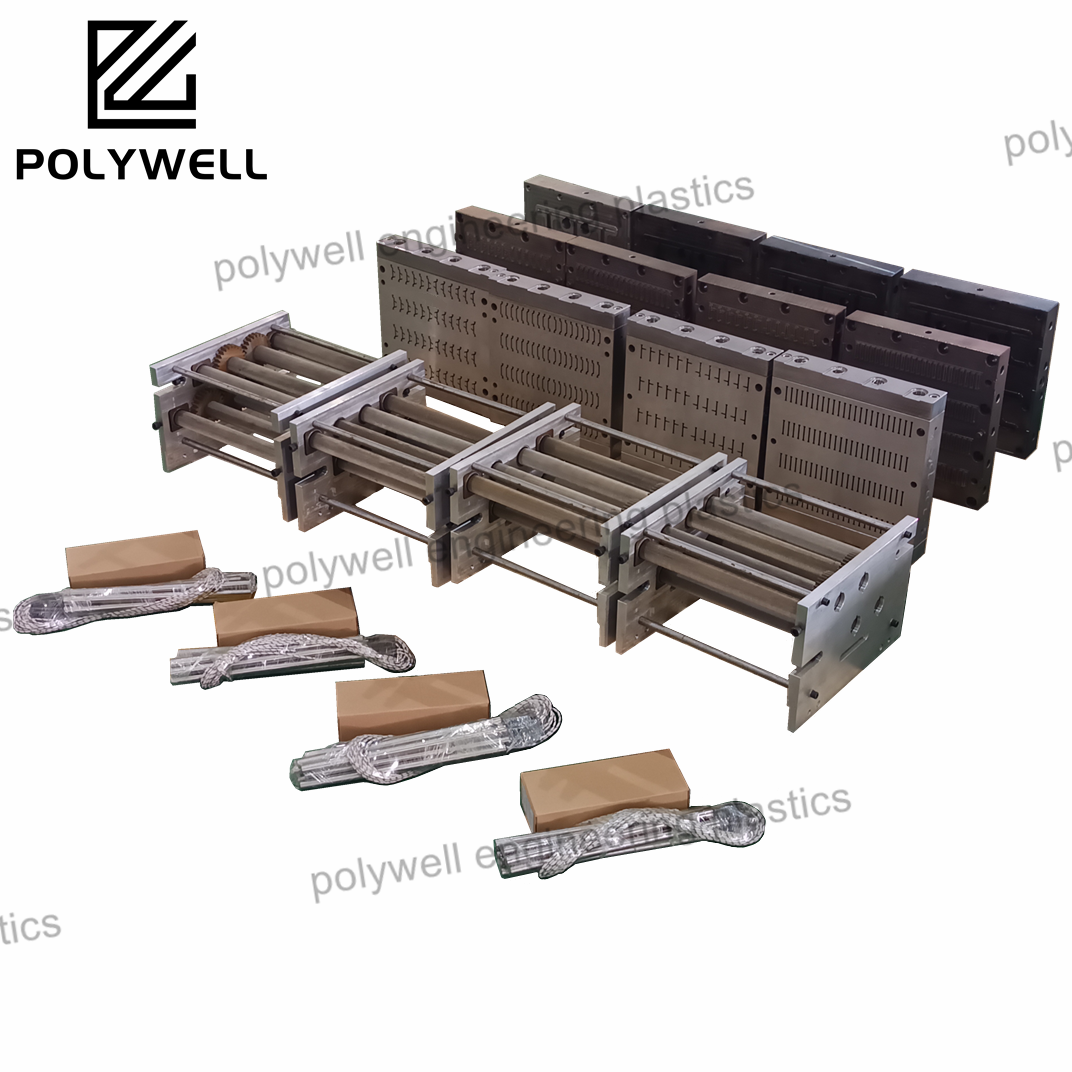

Types of Extrusion Molds Used by POLYWELL There are various types of extrusion molds which POLYWELL uses for thermal break strip specific requirements.The following are:

Base Molds These molds are used to form the basic strip shape profile and are economical so that insulation performance is also reasonable in terms of uniform profile.

Injection Molds: These are used for polymer modifying the strip to add properties such as color, texture, and increased insulation.

Cold Molds These molds are used with materials that set at lower temperatures which is an extra custom feature or performance.

In the production of thermal break strip, POLYWELL’s use of extrusion molds is the most advanced in terms of performance and effectiveness. Depending on specific requirements, advanced molding technology was applied and a variety of molds offered to ensure quality product for energy efficient construction.