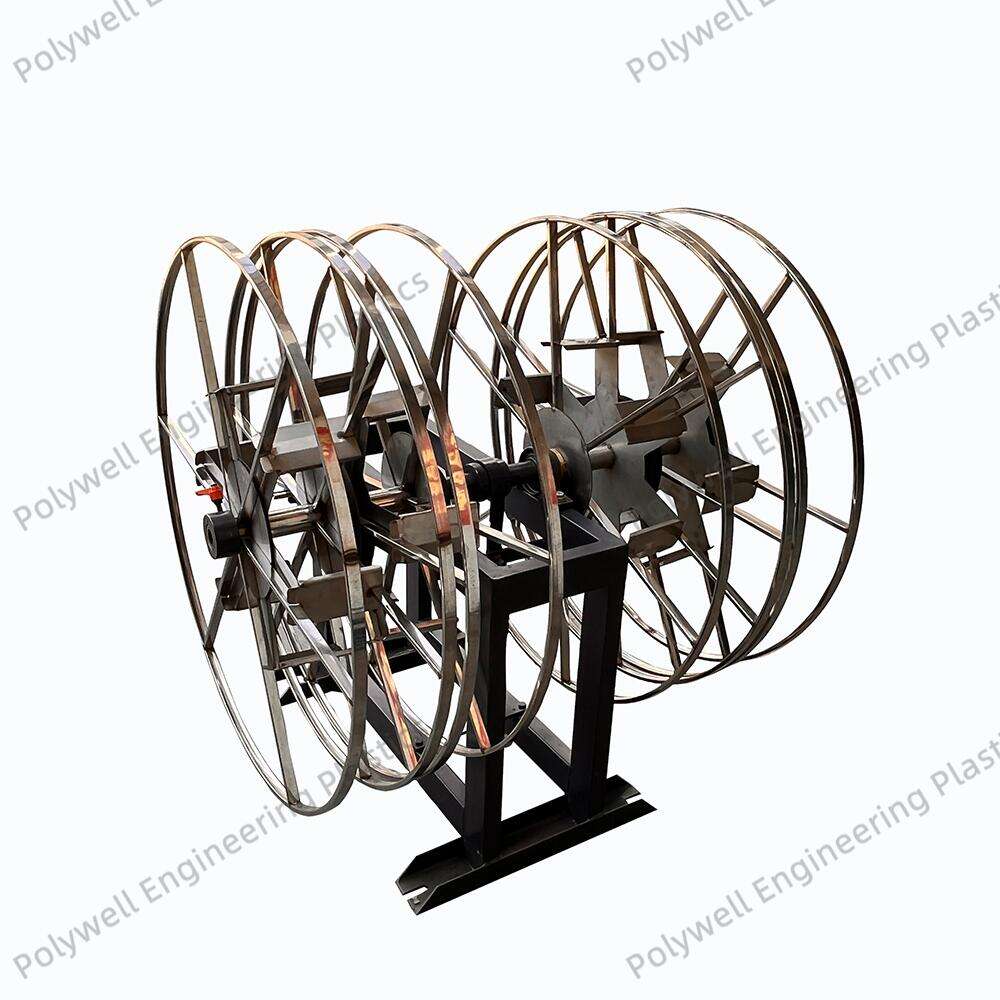

The thermal break strips would not have been possible to produce without the winding machines. POLYWELL possesses this advanced thermal break production technology. According to POLYWELL, these winding machines are essential for ensuring precision in the application of thermal break strips to the aluminum profiles, accentuating the value of the WINDING MACHINE.

What is a Winding Machine?

Winding machines are commonly referred to as simple drawing machines. These are specialized machines that turn the drawn out wires into reels for storage or transportation. Winding machines use a number of non-woven fabrics and thermal break strips as raw materials, ensuring their proper placement throughout the thermal break strip cutting process. They also allow for the automatic cutting of thermal break strips to a specified length. POLYWELL’s advanced technology allows for high levels of mass production under continuous and smooth operation.

How Winding Machines Enhance Production Efficiency

POLYWELL’s contribution toward improving the general thermal break production processes and performance via its material bayouging technology is designed to meet the needs of architects. This is because architects prefer building projects with wider thermal break profiles and reduced dimensional deviations. With respect to the POLYWELL thermal break strips and profiles, standard production tolerance has been significantly reduced. The only mechanical factor that can be controlled without violating the deformation tolerance is the tension on the wound fabric, which results in reduced material consumption, thereby improving the profitability of the thermal break manufacturing process.

POLYWELL's Winding Machines Sophisticated Features

With adjustable tension control, winding speed, and automatic stopping features, POLYWELL’s winding machines are equipped with advanced features. Such features make it simple for operators to adjust themselves in order to get the best quality winding while making the least number of errors. Moreover, the typical design of POLYWELL’s machines provides them with the capability of winding different widths and lengths of thermal break strips thus providing the room for variety in production.

Why Do Manufacturers Prefer POLYWELL's Winding Machines For Thermal Break Strips?

It is one of the top goals of POLYWELL to focus on developing winding machines that excel in performance and quality in the market. By opting for POLYWELL’s technology, manufacturers can assure the correct winding of thermal break strips that comply with the required IEC standards. Be it an extensive manufacturer or a small sized company, POLYWELL has the best answers for your production requirements.

The winding stage is a very important part in manufacturing thermal break strips. With the use of POLYWELL’s advanced winding machines, manufactured goods manufacturers can increase their productivity, enhance the overall quality of the goods produced, as well as meet the increased demand for energy efficient building materials.