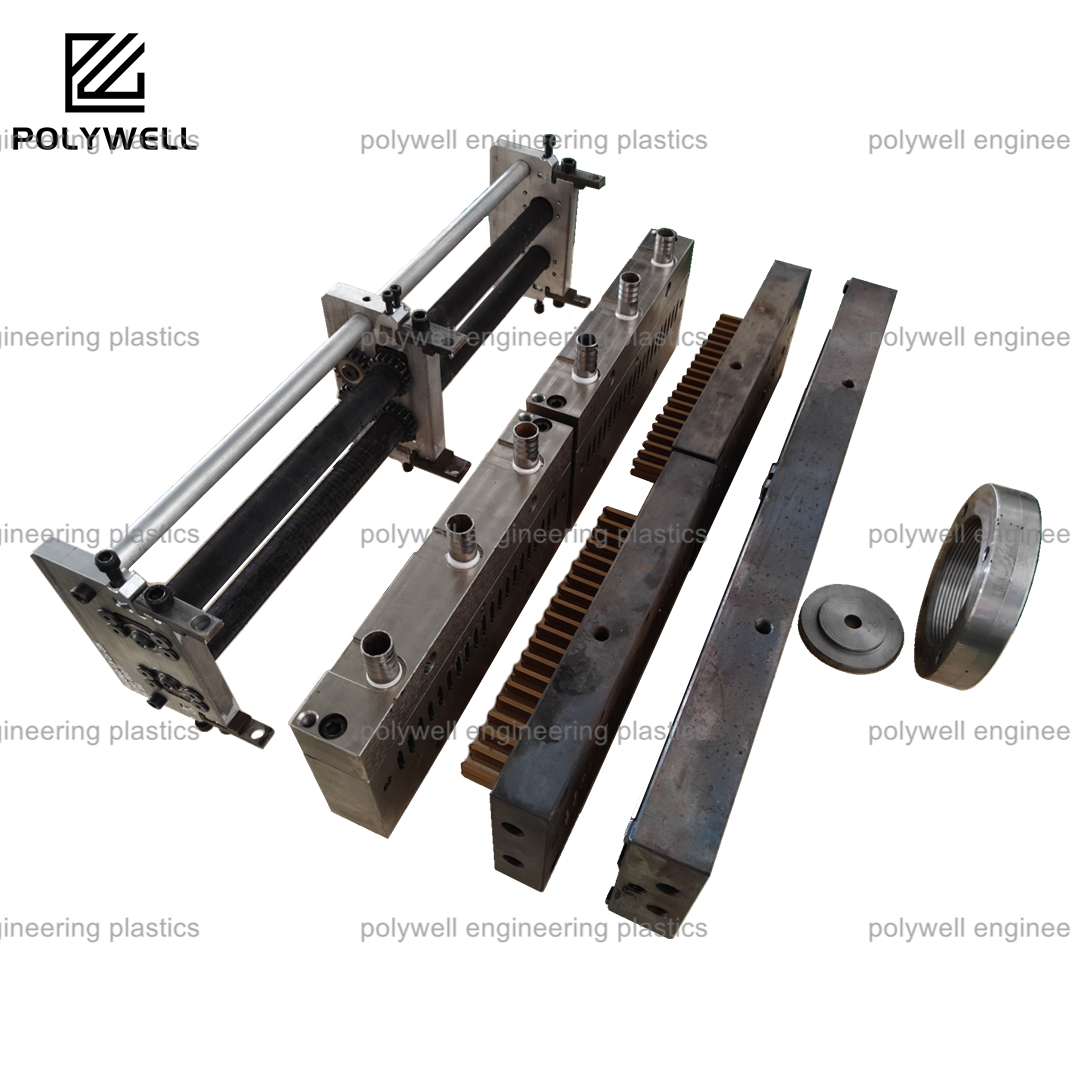

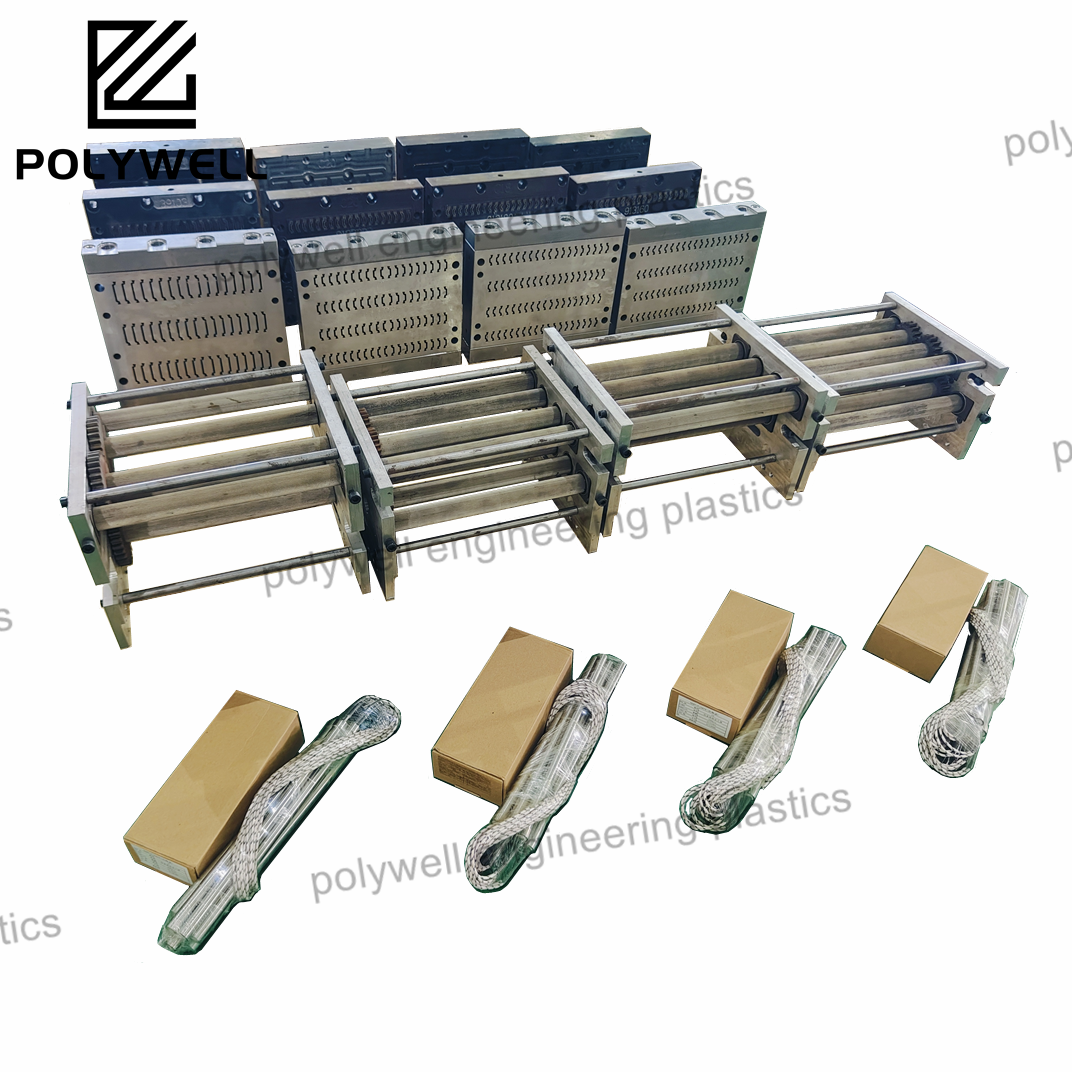

Injection mold design is the engineering foundation of plastic injection molding, encompassing the systematic development of tooling systems that shape molten polymer into finished components. This complex process integrates multiple engineering disciplines to create molds that operate reliably under extreme conditions of pressure, temperature, and cyclic loading. The design sequence begins with comprehensive analysis of the part design, identifying potential manufacturing challenges and applying design for manufacturability (DFM) principles to optimize the geometry for production. Critical design elements include the cavity and core system, which must accommodate material shrinkage and incorporate appropriate surface finishes; the feeding system, which controls material flow into the cavity; the cooling system, which regulates thermal conditions for dimensional stability; the ejection system, which facilitates part removal; and the structural system, which withstands injection pressures. Advanced molds incorporate complex mechanisms for producing undercuts, threads, and other special features, often requiring sophisticated actuation systems. Material selection for mold components is based on production requirements, with options ranging from aluminum for prototype tools to hardened tool steels for high-volume production. Modern injection mold design extensively utilizes CAD/CAE software for 3D modeling, simulation, and analysis, enabling engineers to predict and address potential issues before tool fabrication. The design process must also consider practical manufacturing concerns including ease of maintenance, repairability, and compatibility with standard molding equipment. Successful injection mold design delivers a manufacturing system that produces dimensionally accurate, cosmetically acceptable parts with minimal scrap while operating efficiently over extended production runs. The economic impact of mold design decisions extends throughout the product lifecycle, influencing part cost, quality consistency, and time-to-market.