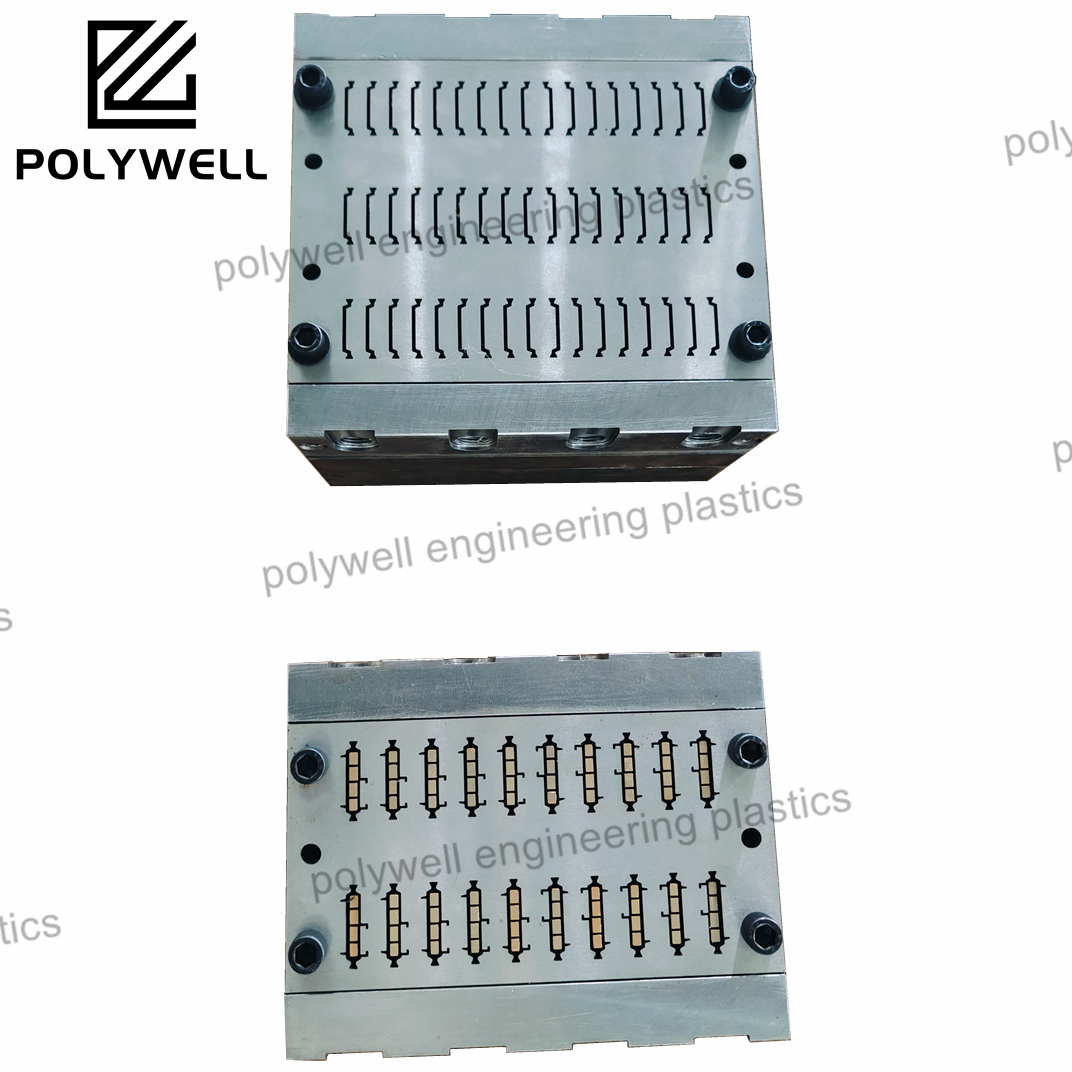

Die mould design, particularly in the context of die casting, represents a specialized engineering field focused on creating durable tooling systems for producing high-volume metal components with complex geometries and tight tolerances. This design process requires comprehensive understanding of metallurgy, thermal management, and fluid dynamics. The fundamental architecture includes the cavity and core system that forms the part geometry, engineered with appropriate shrinkage allowances for the specific alloy being cast. The feeding system design is critical, comprising sprue, runners, and gates optimized to control metal flow velocity, reduce turbulence, and ensure proper cavity filling sequence. Overflow wells and venting channels are strategically placed to capture cold metal and allow air escape during injection. Cooling system engineering employs complex channel networks following the mould contours to extract heat uniformly, control solidification patterns, and maintain thermal balance throughout the production cycle. Ejection system design must overcome the significant adhesion forces between the cast metal and mould surfaces, incorporating precisely positioned pins, sleeves, and stripper plates. For complex components, movable cores, slides, and unscrewing mechanisms are integrated with precise actuation systems. Material selection focuses on premium hot-work tool steels with exceptional thermal fatigue resistance, high temperature strength, and good thermal conductivity. Surface treatments like nitriding, chromium plating, or specialized coatings enhance wear resistance and prevent soldering. Modern die mould design extensively utilizes simulation software for analyzing mold filling, solidification, thermal stresses, and predicting potential defects. The design must also accommodate thermal expansion during operation, provide adequate structural support to withstand injection pressures, and ensure maintainability throughout the tool's operational life. Successful die mould design delivers a manufacturing system capable of producing millions of high-integrity components with consistent dimensional stability and surface quality, serving critical applications in automotive, aerospace, and consumer goods industries.