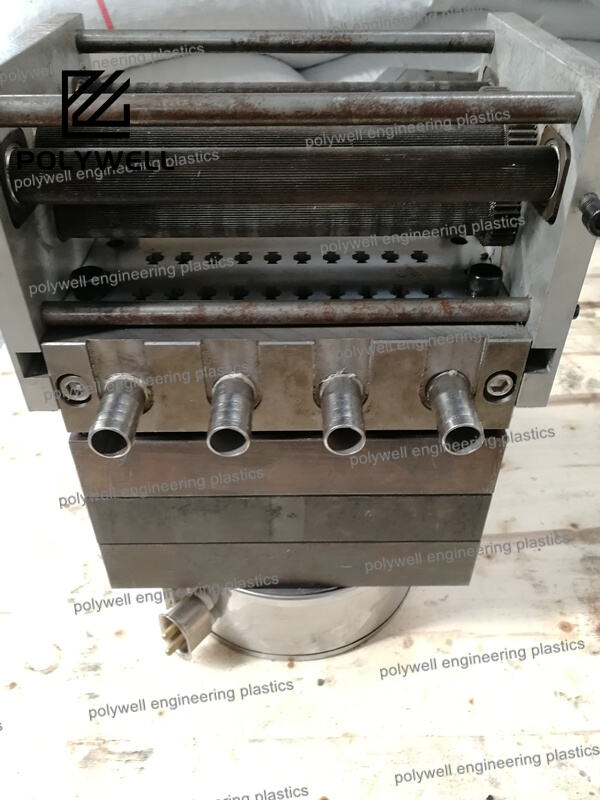

Die mold design, particularly in the American English context where "mold" is spelled with a single 'o', represents the engineering process of creating tooling systems for manufacturing components through processes like die casting and injection molding. This discipline requires multidisciplinary knowledge spanning material science, thermal dynamics, and mechanical engineering. The design process begins with comprehensive analysis of the product geometry, identifying features that require special tooling actions such as side-cores for undercuts or collapsible cores for internal threads. The feeding system design is crucial, involving sprue, runners, and gates optimized for the specific material being processed—whether molten metal for die casting or polymer for injection molding. Cooling system engineering employs strategically placed channels to control thermal conditions, with precise calculations for heat extraction rates to maintain consistent cycle times and dimensional stability. Ejection system design must overcome material adhesion forces while preventing part damage, incorporating pins, sleeves, and stripper plates positioned at optimal locations. For complex geometries, additional mechanisms including lifters, sliders, and unscrewing devices are integrated with precise actuation systems. Material selection focuses on tool steels with properties matched to the application—thermal fatigue resistance for die casting, wear resistance for abrasive materials, and polishability for high-gloss surfaces. Modern die mold design extensively utilizes simulation software for analyzing flow patterns, cooling efficiency, and structural integrity under operating conditions. The design must also accommodate thermal expansion, provide adequate venting for air escape, and ensure maintainability throughout the tool's operational lifespan. Venting design prevents air entrapment that causes defects, while alignment systems maintain precision during high-pressure operations. Successful die mold design delivers a manufacturing system capable of producing high-quality components with consistent dimensional accuracy and surface finish while operating reliably over hundreds of thousands of cycles.