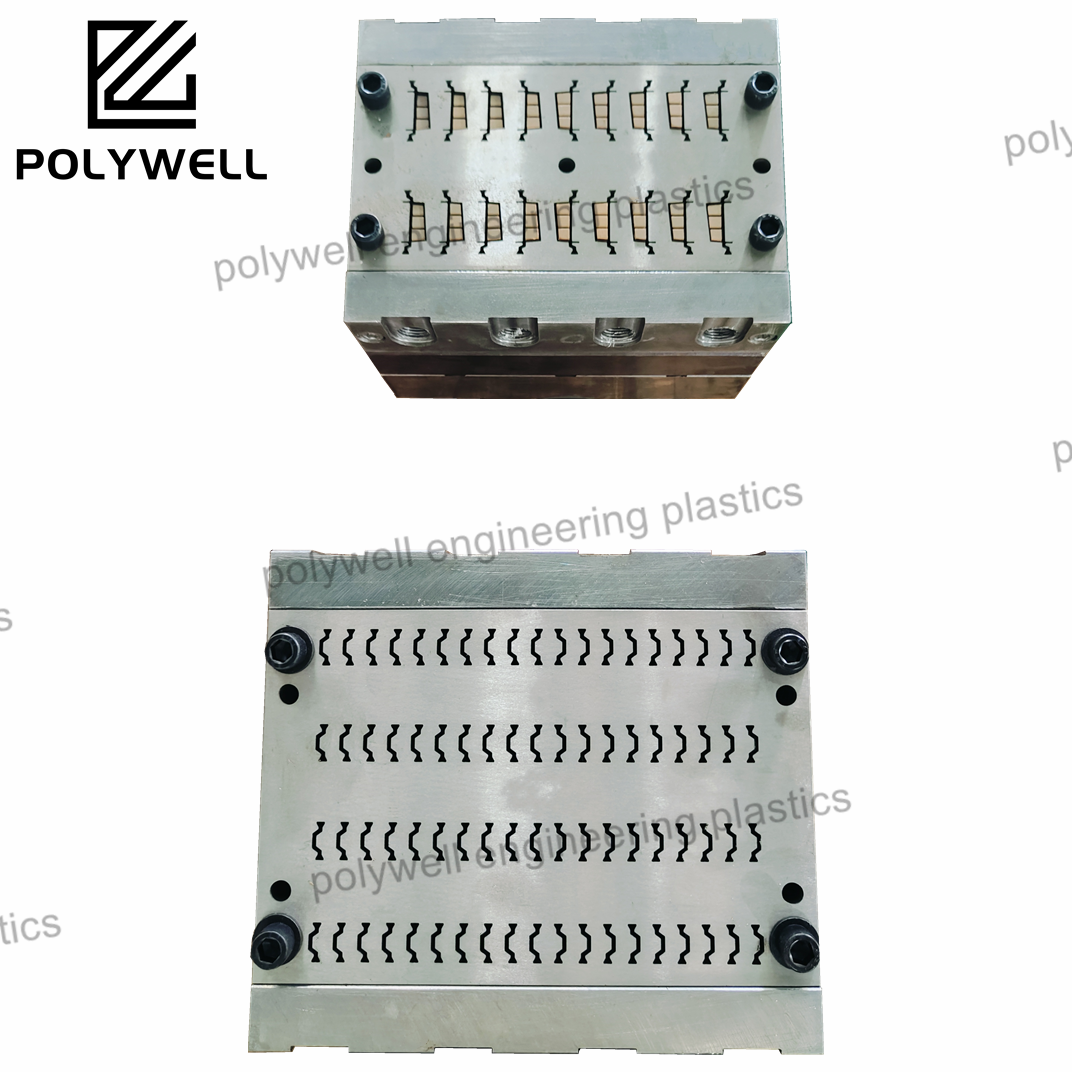

Injection molding tool design, often termed mold design, is the foundation of efficient plastic part production, involving the creation of robust molds that shape molten polymer into finished components. This process encompasses cavity and core design, runner systems (cold or hot runners), gating mechanisms, and ejection setups. Key elements include selecting mold materials like tool steels (e.g., D2 or S7) for durability and wear resistance, and incorporating cooling channels to regulate temperature and cycle times. Designers must balance factors such as part geometry, material flow, and shrinkage to avoid defects like short shots or flash. Advanced techniques involve multi-cavity molds for high-volume output and side-actions for undercuts, requiring precise alignment and tolerance control. The use of CAD/CAM software enables 3D modeling, simulation of injection processes, and optimization of venting systems to eliminate trapped air. Maintenance considerations, such as easy access for cleaning and repair, are integral to prolong mold life. In industries like packaging, medical, and automotive, tool design adheres to standards like SPI classifications to ensure quality and interoperability. Collaboration with part designers and manufacturers is essential to address challenges like cost constraints and production scalability, ultimately driving innovation and reliability in global supply chains.