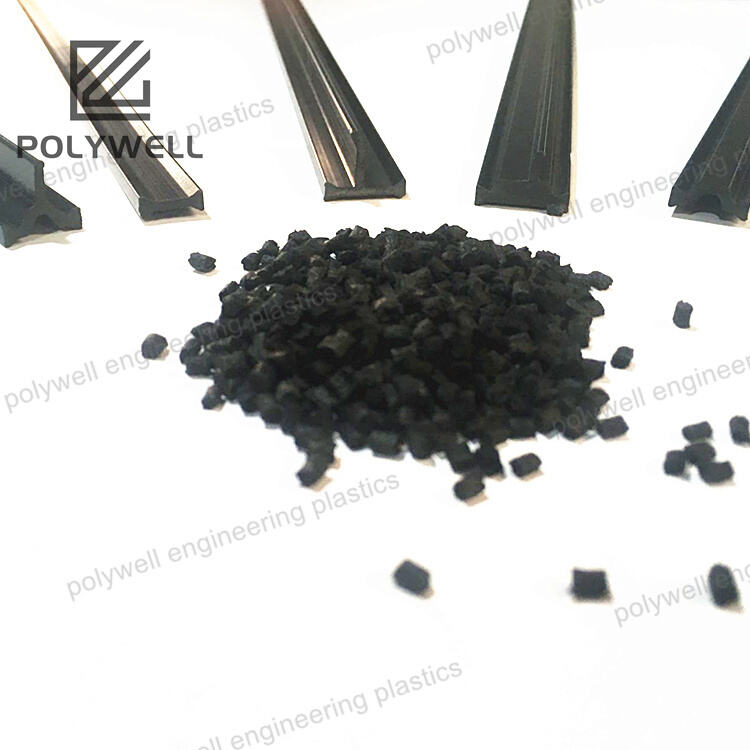

Recycled Polyamide refers to nylon materials that have been recovered from post-industrial or post-consumer waste and reprocessed into new, usable polymer granules. This sustainable material stream is increasingly critical for reducing environmental impact and promoting circular economy principles within the plastics industry. The recycling pathways include mechanical recycling, where nylon waste is sorted, cleaned, shredded, melted, and re-pelletized, and chemical recycling, which depolymerizes the material back to its monomers for repolymerization into virgin-quality resin. Post-industrial waste, such as sprues and runners from injection molding, provides a consistent and clean source for high-quality recycled content. Post-consumer sources are more complex, including carpet fibers, fishing nets, and end-of-life automotive parts, requiring sophisticated sorting and purification processes. The primary challenge with mechanically recycled polyamide is the potential degradation of molecular weight during multiple heat histories, which can lead to a reduction in intrinsic viscosity and, consequently, some mechanical properties like impact strength and elongation at break. To counteract this, chain extenders or stabilizers are often added during reprocessing. Furthermore, ensuring consistency in color and properties can be challenging due to potential contamination. Despite these challenges, recycled polyamide finds substantial applications in non-aesthetic automotive components, electrical connectors, and various consumer goods where high performance is required but virgin-quality optics are not essential. Using recycled polyamide significantly reduces the carbon footprint and energy consumption compared to producing virgin material, making it an environmentally and often economically advantageous choice for manufacturers committed to sustainability.