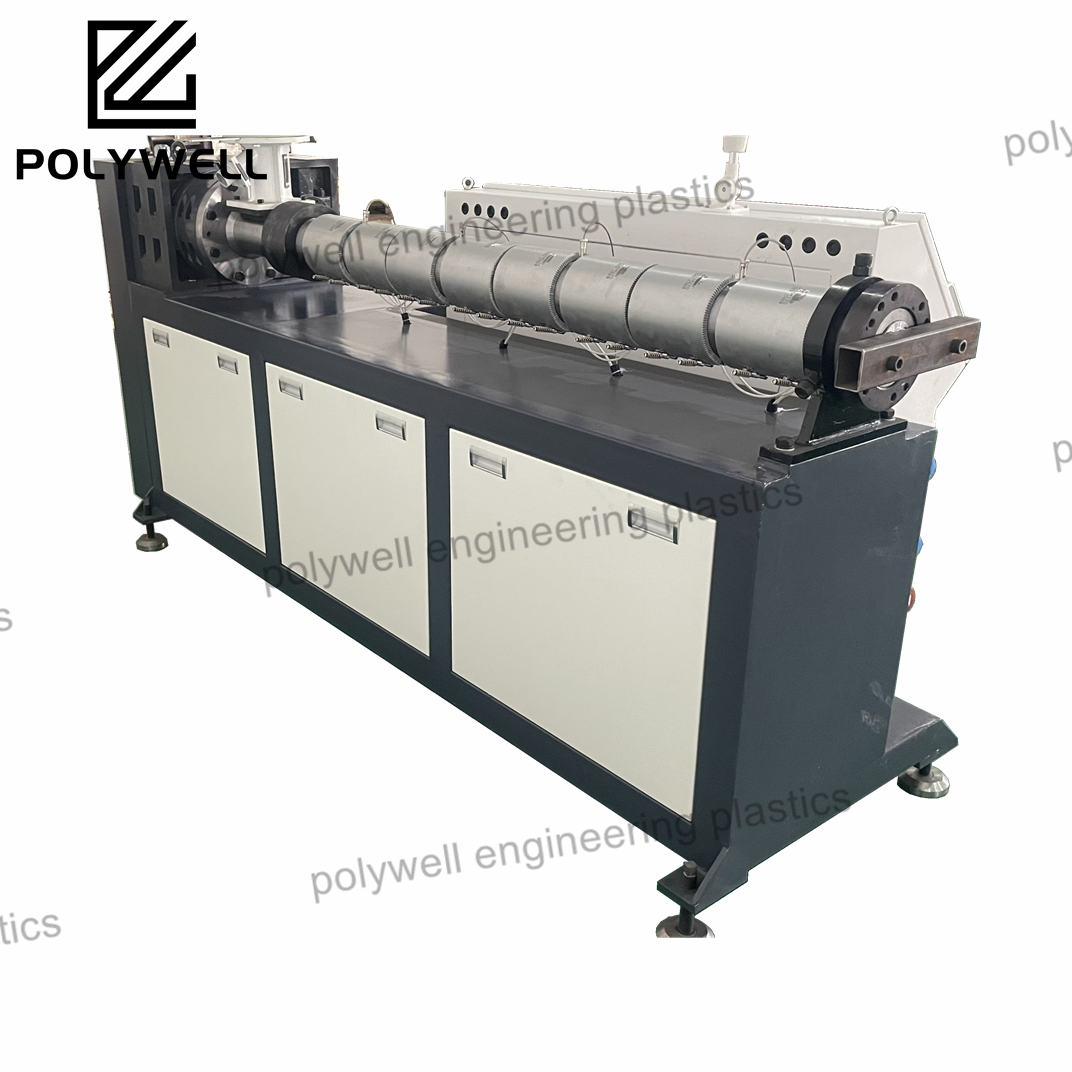

A sustainable mindset has a chance to expand and thrive in any manufacturing industry including thermal break strip. POLYWELL’S single screw extruder is one of the solutions that is not only efficient but also has a minimal negative impact on the environment.

Energy Savings Considerations

The basis behind POLYWELL’s efforts in sustainability is the Direct Drive System. This breakthrough feature translates to lower energy consumption since inefficiencies in power transmission are eliminated. Reducing energy use directly reduces operating costs and has eco-friendly impacts.

Reducing the Volume of Overproduction

Material wastage during the production stage is optimized since POLYWELL’s extruder is engineered to precision. This is very significant for the thermal break strip manufactures where the focus on uniformity and accurate dimensions is of paramount importance.

Increased Usage Life and Performance

Another factor which aids with sustainability within POLYWELL’S single screw extruder is the design. Less replacement and maintenance are required thus this extruder is resource efficient throughout its lifecycle.

Advancing Ecofriendly Solutions for Architecture

The strips while placed in between the two sash rails prevents heat transfer, thus POLYWELL’S extruder provides a fastener for green construction. It helps achieve energy savings and improves the efficiency of buildings while allowing for minimal GHG footprint.

POLYWELL's single screw extruder is not an ordinary production machine; it is a staunch optimism developer. Due to its eco friendly approach and efficient working, it is a very important tool for those manufacturers who are serious about protecting the environment.