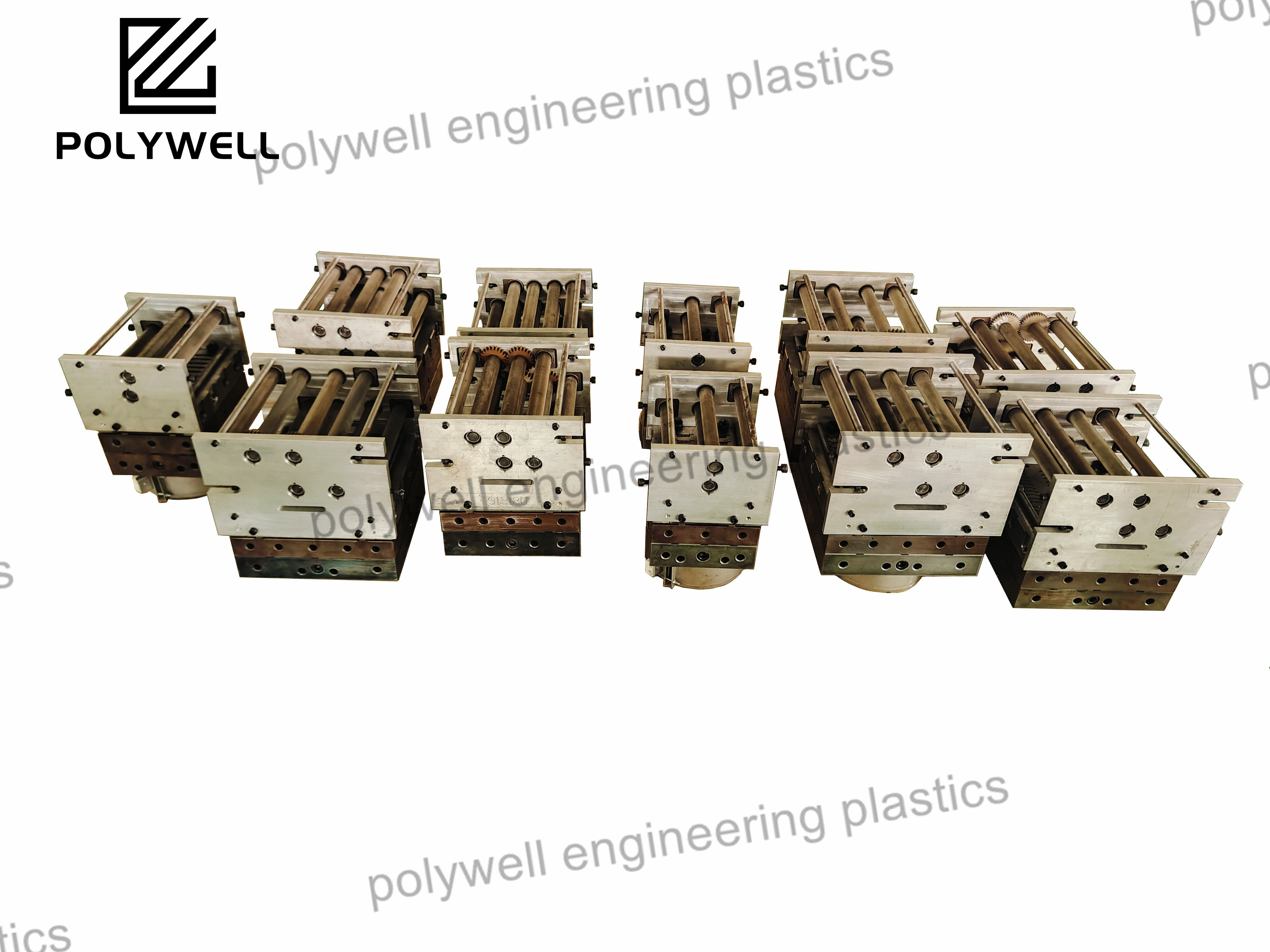

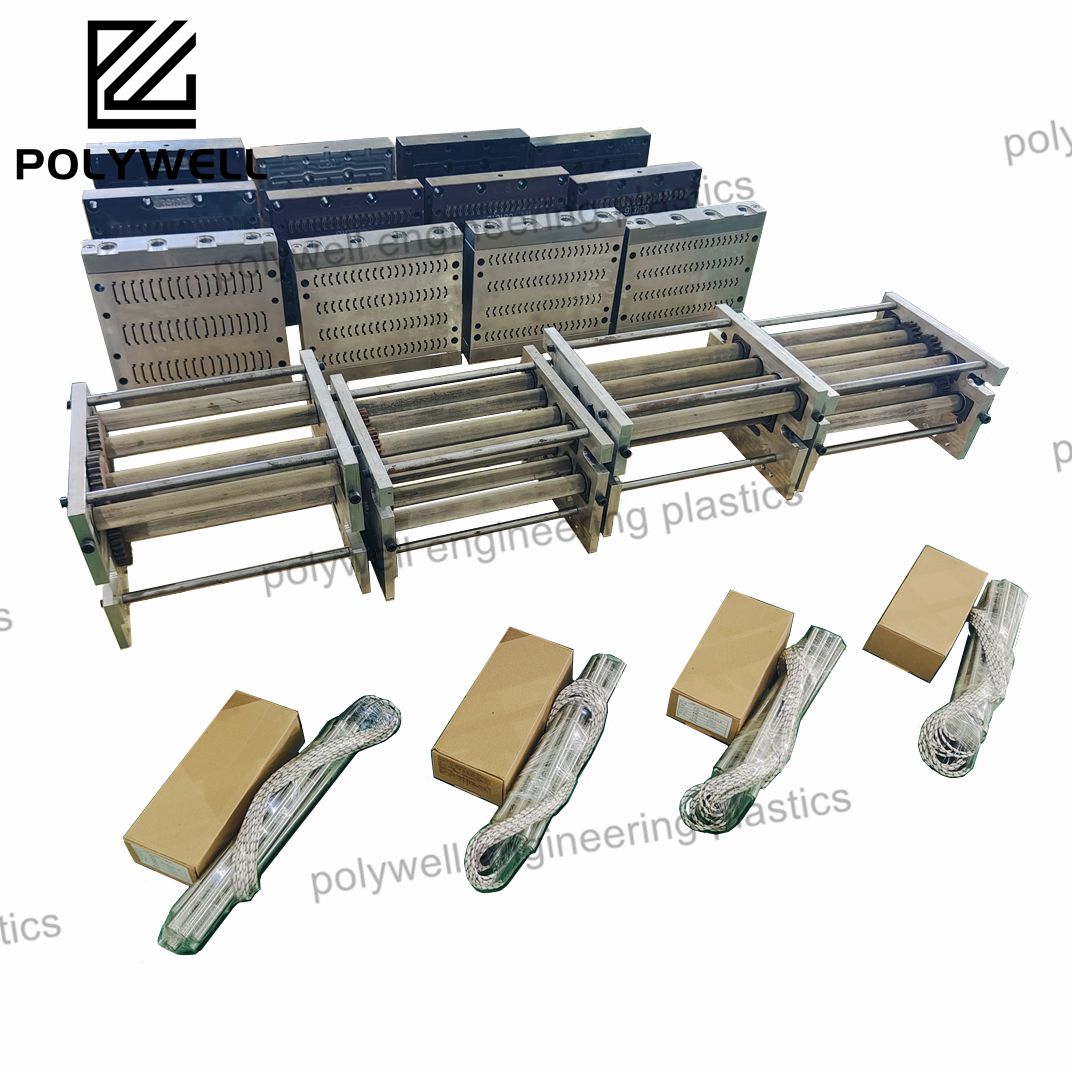

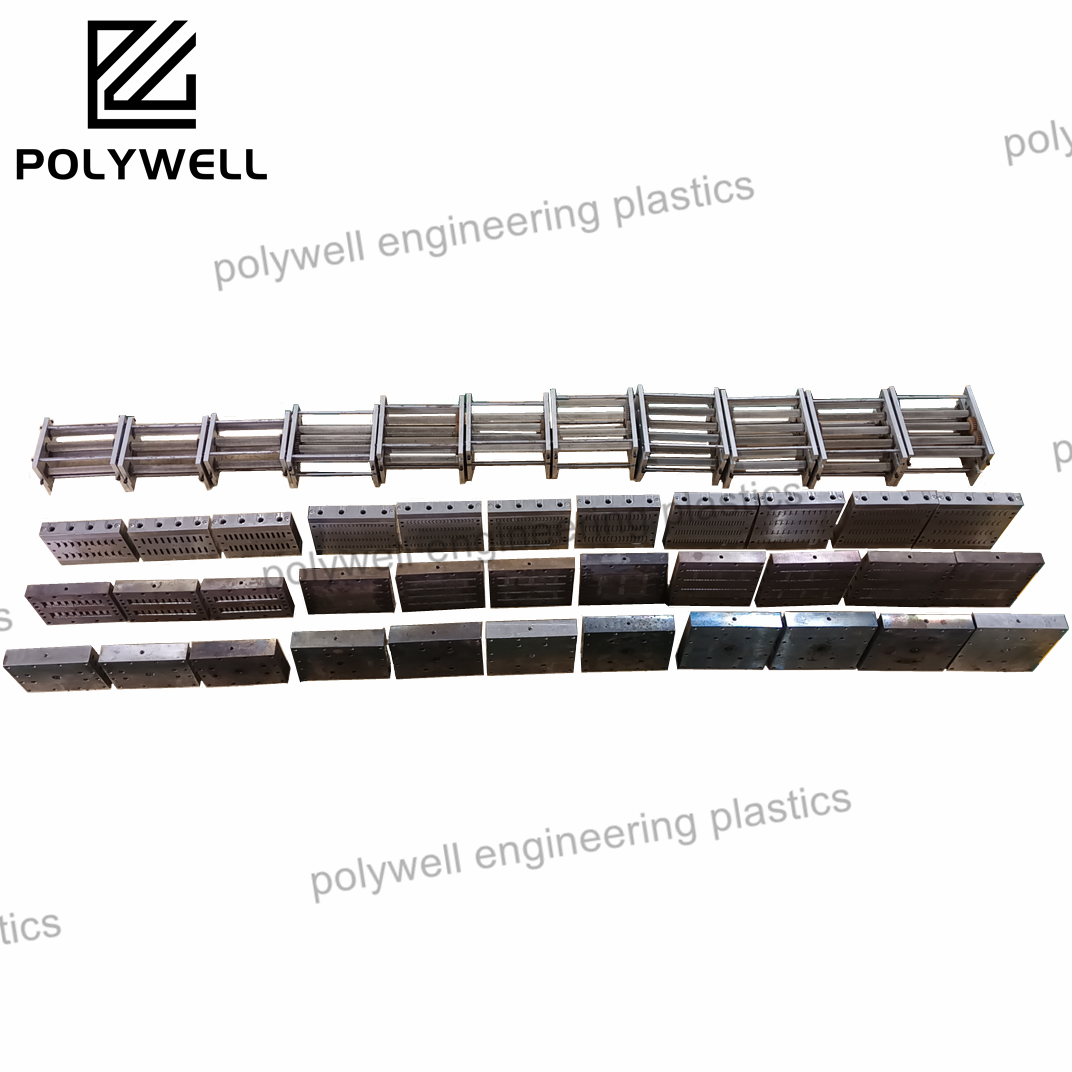

Plastic extrusion manufacturers are industrial entities that operate extrusion plants, transforming raw plastic resins into finished or semi-finished goods. They are defined by their ownership and operation of the physical production assets—the extrusion lines themselves. Their business model centers on the efficient and high-quality conversion of polymer granules into saleable products like profiles, pipes, or sheets. This involves a deep operational focus on process optimization, maintenance scheduling, raw material inventory management, and labor deployment. Manufacturers invest heavily in capital equipment, from the extruders and dies to the downstream handling and packaging systems. They are responsible for the entire production workflow, ensuring that the machinery is calibrated, the process parameters are set correctly for each product, and rigorous quality control checks are performed throughout the run. Many plastic extrusion manufacturers also have in-house tooling departments for designing and maintaining the critical dies and calibration fixtures. Their expertise is practical and hands-on, rooted in a thorough understanding of how machine settings, material lot variations, and ambient conditions affect the final product. They are the foundational producers in the supply chain, whose capability and reliability directly determine the availability and quality of a vast array of plastic components used in everyday life and industrial applications.