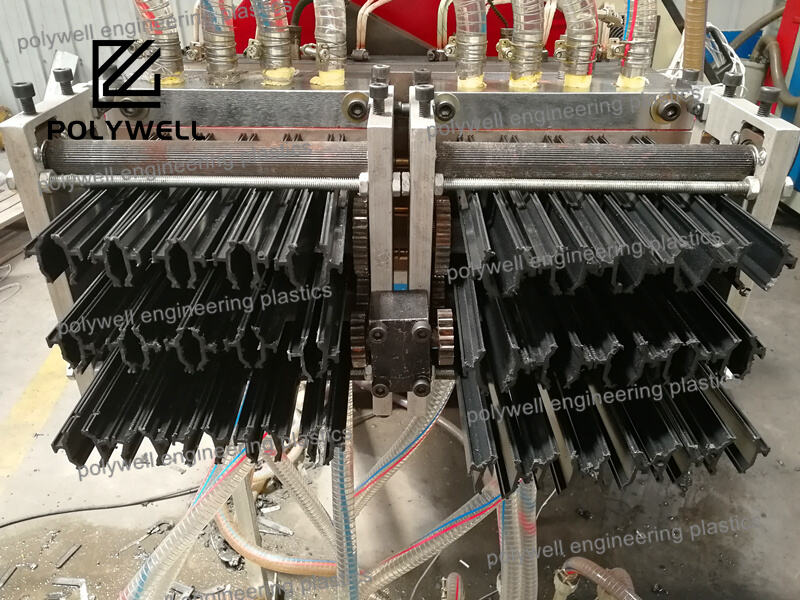

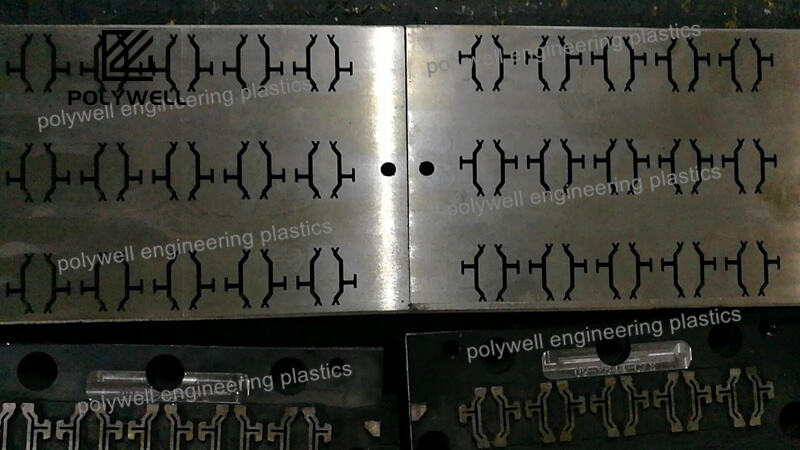

Plastic extruder machine manufacturers are specialized engineering firms that design, build, and supply the core equipment for the extrusion process, which is fundamental to producing a vast array of plastic products, from films and pipes to profiles and sheets. These manufacturers offer a spectrum of machinery, from small laboratory-scale units to massive, multi-extruder lines for industrial production. The heart of their product line is the extruder itself, which consists of a barrel containing a rotating screw, a drive system, a heating/cooling system, and a control unit. Reputable manufacturers differentiate themselves through the precision engineering of the screw and barrel, which are the heart of the extrusion process. They design screws with specific compression ratios and mixing sections tailored to the flow characteristics of different polymers, such as the high-temperature processing required for PA66. Beyond the basic extruder, these companies often provide complete turnkey systems, which include upstream components like material dryers and hopper loaders, and downstream equipment such as calibration tanks, haul-offs, cutting machines, and winding or stacking systems. The selection of a manufacturer is a critical decision, based on their technical expertise, after-sales service, availability of spare parts, and their track record in a specific market segment, such as precision profile extrusion for the construction industry. A manufacturer with deep experience in thermal break profiles, for instance, will understand the nuances of processing glass-filled nylons and can provide a line optimized for that purpose, ensuring consistent quality and dimensional stability in the final product.