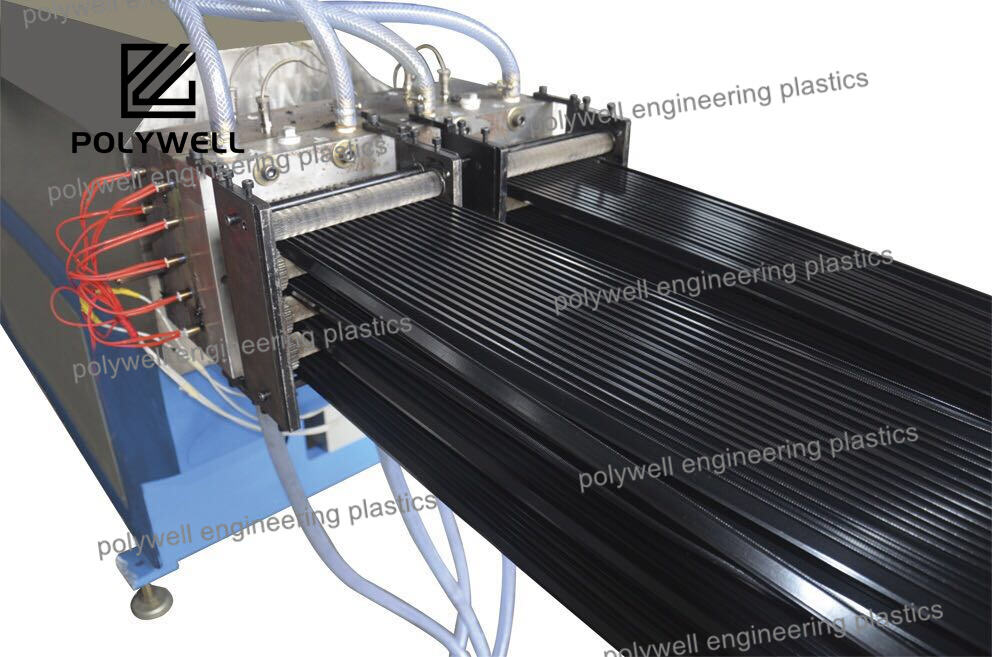

The price of a plastic extruder machine is highly variable, ranging from tens of thousands of dollars for a small, basic lab model to several million dollars for a complete, high-output production line. The cost is influenced by a multitude of factors. The first is the size and output capacity, typically defined by the screw diameter (e.g., 45mm, 60mm, 90mm) and its L/D ratio (length-to-diameter ratio). A larger machine with a higher L/D ratio for better mixing and melting will command a higher price. The type of extruder is another major factor; a simple single-screw extruder is the most economical, while a co-rotating twin-screw extruder for compounding or processing technical polymers is significantly more expensive due to its complex screw and barrel design. The specification of the components also drastically affects the price. A machine built with a standard AC motor and basic heater bands will cost less than one with a energy-efficient servo drive and advanced ceramic heaters. The level of automation and the sophistication of the control system (from simple PID controllers to full PC-based SCADA systems) represent a substantial portion of the cost. Furthermore, the price is heavily dependent on the auxiliary equipment included. A quote for a "bare" extruder is just the beginning; the cost of essential downstream equipment like dies, calibration tables, haul-offs, cutters, and winders must be factored in to understand the total investment. Finally, the reputation and support network of the manufacturer influence the price, with established brands with global service networks typically charging a premium that is often justified by greater reliability and support.