Creating effective thermal insulation strips go beyond sourcing for quality raw materials or investing in proper casting machines that are designed for specific applications. It is beyond a doubt that POLYWELL has risen to the top of manufacturers for extrusion molds thanks to its superior controlled technology .

The Necessity of Thermal Insulation Extrusion Molds

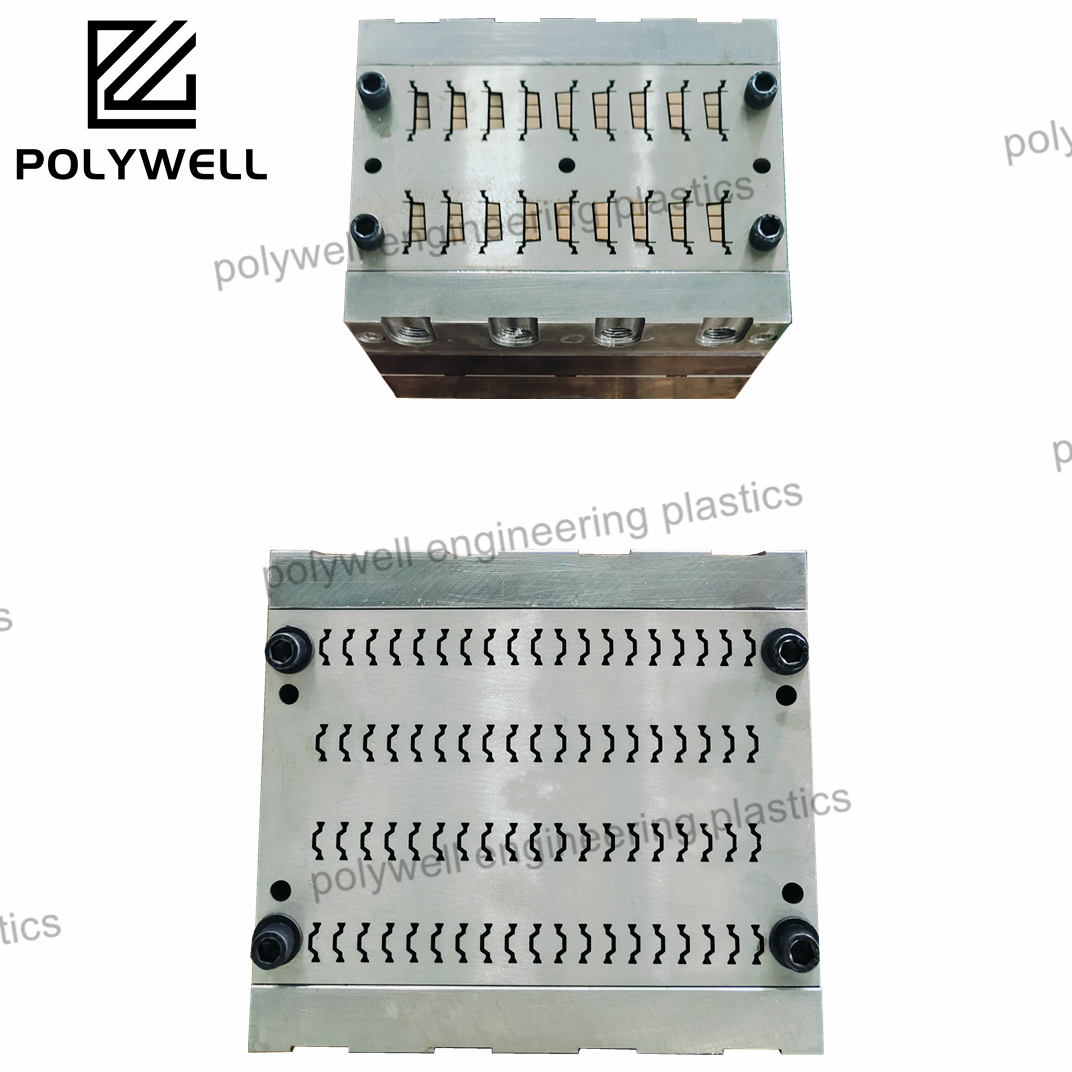

The extrusion molds are key components in the manufacturing of the PA66 thermal insulation which is necessary in the making of windows and doors that are energy efficient. To produce the desired end product, PA66 extrusions should conform to a specific tolerancing system. Most importantly, as a design factor, it has to be taken into account in the design of production molds what the cold working shrinkage rate of PA66 will be after production has been achieved.

Engineering Methods for Shrinkage Control

When undertaking mold manufacturing, one of the toughest challenges is adjusting for shrinkage material. To solve this problem POLYWELL use the unique simulation software and its patented algorithm to determine the scale factor which is needed. This however means that the cold mold design should be right so that customers create strips of required measurements.

Custom Mold Solutions

At POLYWELL, we know everyone has custom needs. Today our team sits with the customers to dissect their production processes and material requirements. We all integrate such information into the mold design steps to provide great solutions to the customers.

Quality Assurance and Testing

POLYWELL molds undergo trial checks and testing to ensure they meet the customer standards. Our process includes trial runs and dimensional analyses to ensure validation of the mold before it’s delivered. Such measures reduce the scope of mistakes and enhance customer satisfaction.

At POLYWELL we are focused on improvement and fulfilling customer needs, which has made us the top in the industry of extrusion molds for production of PA66 thermal insulating strips. Thanks to the accurate engineering and assistance, our customers never have problems reaching their production aims.