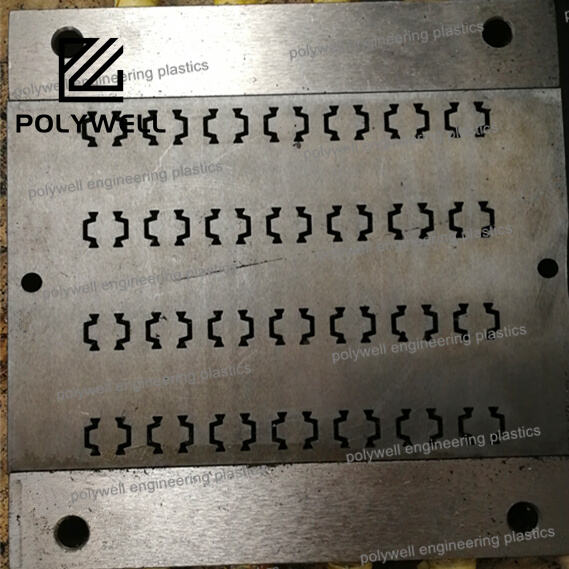

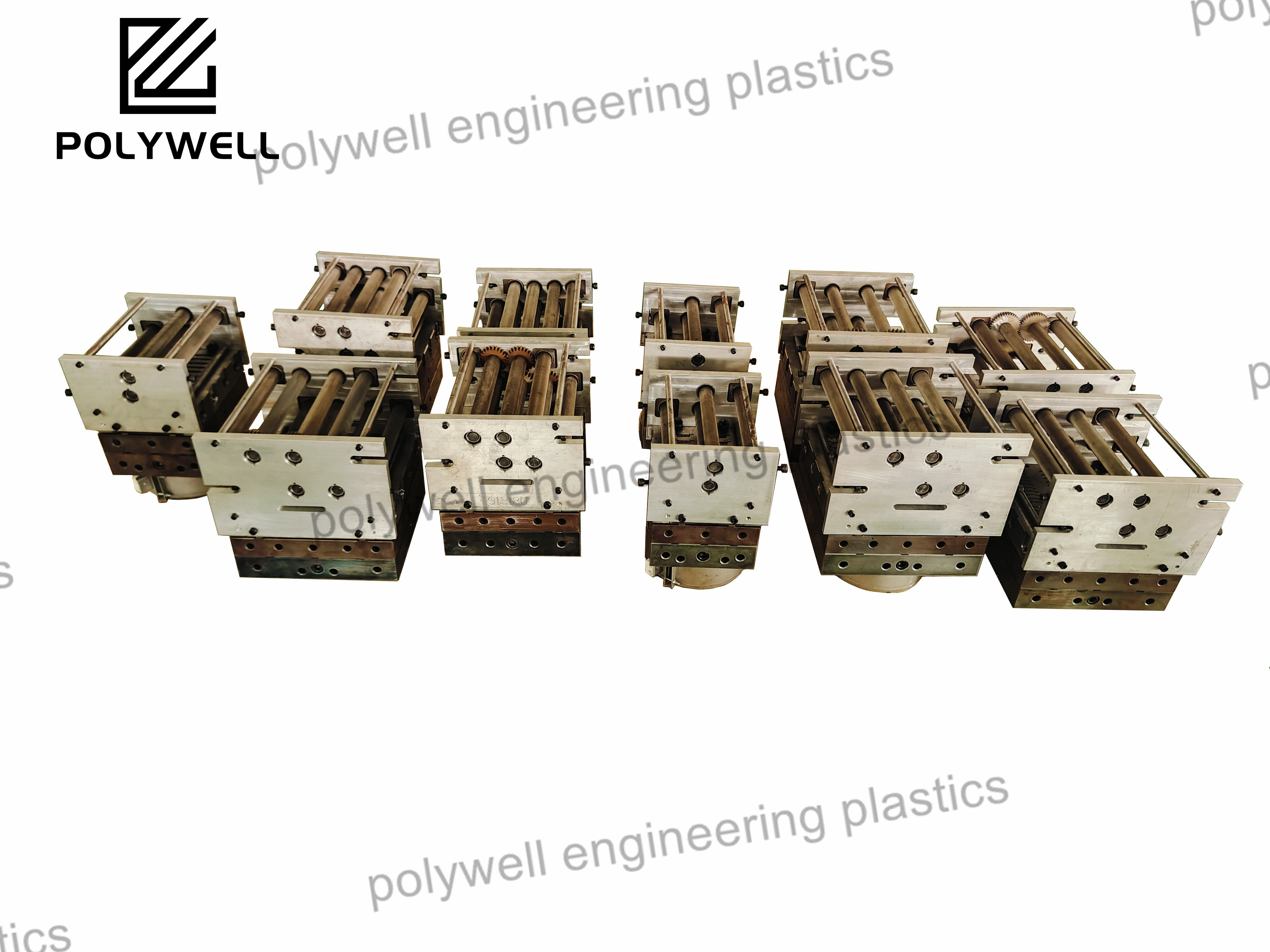

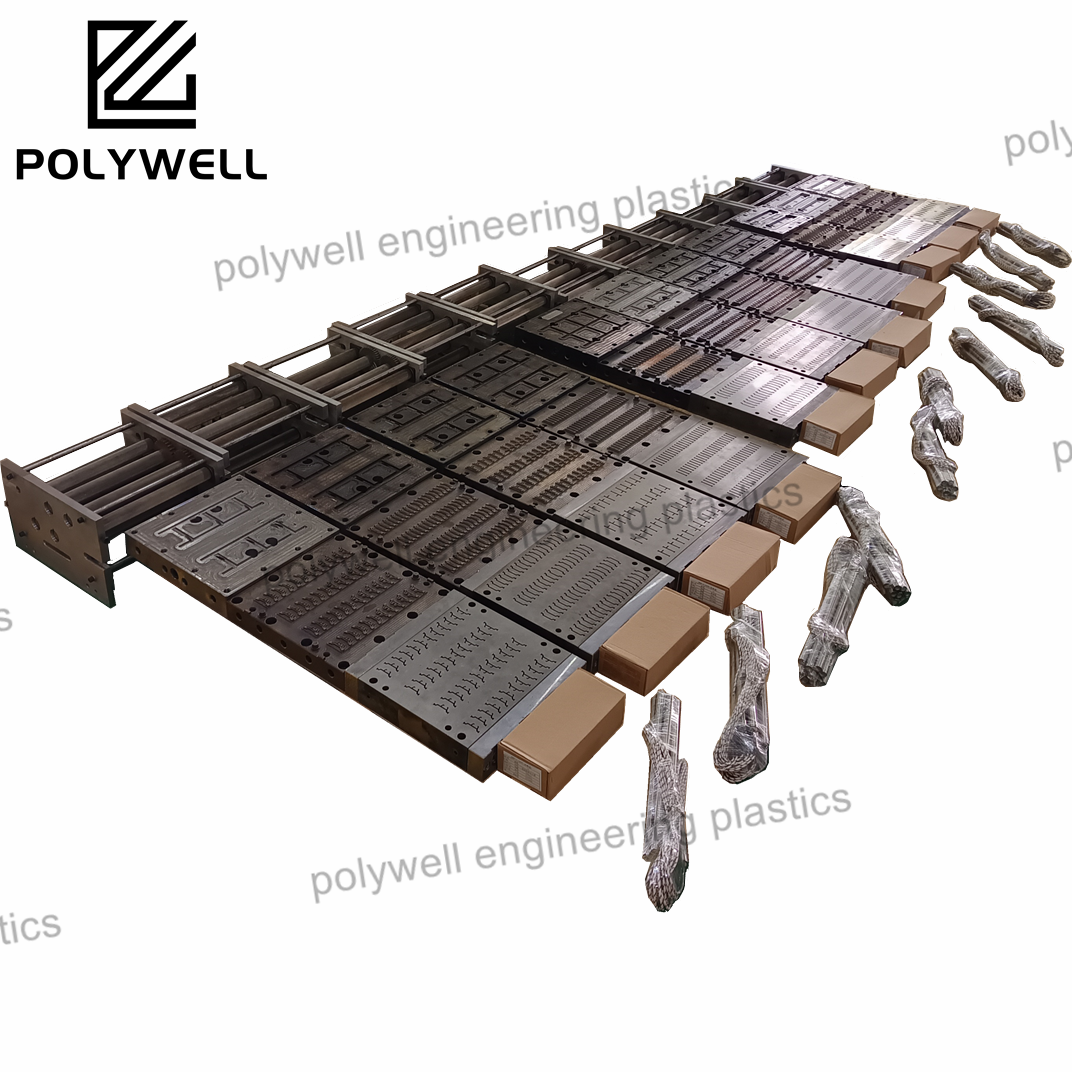

An extruded plastic profile is a continuous length of plastic with a specific and constant cross-sectional shape that is manufactured through the extrusion process. These profiles represent one of the most common and versatile product forms in the plastics industry, found in applications ranging from simple decorative trims to critical structural components. The geometry of the profile is determined by the design of the die through which the molten plastic is forced. Profiles can be solid, hollow, or multi-chambered, and their design is often optimized for specific functions such as structural stiffness, thermal insulation, or as a track for guiding moving parts. The material selection is critical and is based on the required properties: PVC for weatherability and cost-effectiveness, Polycarbonate for impact resistance, Acetal for low friction, and glass-filled Polyamide (e.g., PA66 GF30) for high strength and thermal performance in applications like thermal break strips for aluminum windows. The quality of an extruded plastic profile is judged by its dimensional accuracy, surface finish, color consistency, and mechanical properties. Achieving this quality requires precise control over the entire extrusion process, including melt temperature, line speed, and cooling rate. The ability to produce complex, tight-tolerance profiles makes extrusion an indispensable manufacturing method for creating customized plastic parts without the need for expensive post-processing.