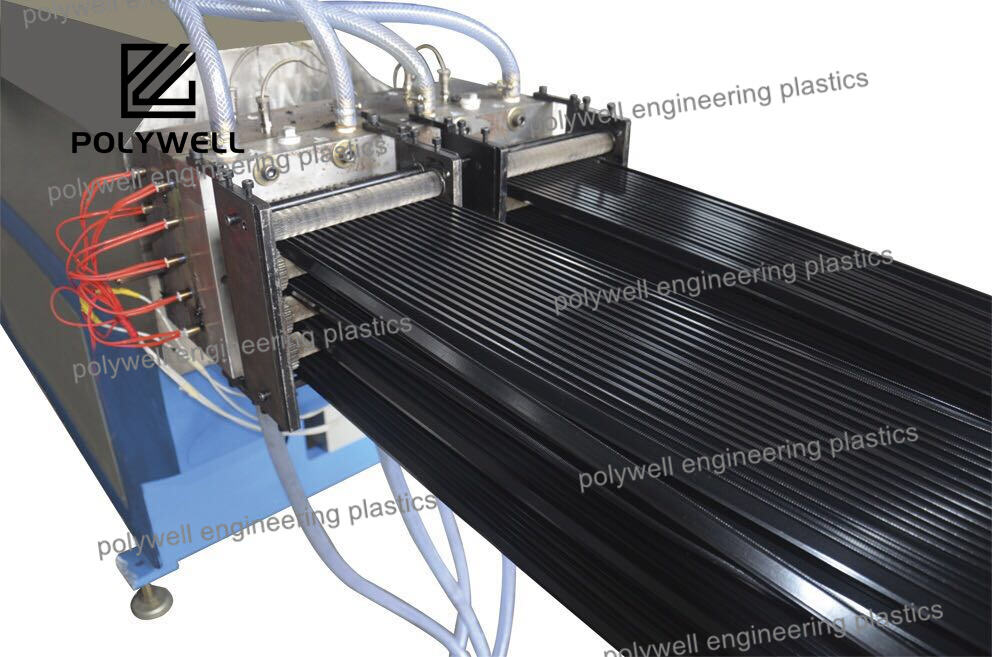

Plastic extruder manufacturers are companies dedicated to the production of the central machine in plastic processing: the extruder. Their focus is on the precise mechanical and thermal design required to plasticize and pump polymer melts consistently. These manufacturers produce a range of extruder types, primarily single-screw and more complex twin-screw extruders, with the latter offering superior mixing and devolatilization capabilities for compounding or processing engineering plastics. The core competency lies in the design and metallurgy of the screw and barrel assembly. They utilize high-grade, wear-resistant alloys and often apply specialized coatings like bi-metallic liners or nitrided surfaces to withstand the abrasive nature of filled materials like glass-reinforced PA66. The drive system must provide sufficient torque at variable speeds to process high-viscosity melts, and the heating and cooling systems must offer precise thermal control across multiple barrel zones to ensure a stable melt temperature. Leading manufacturers invest heavily in R&D to develop energy-efficient drives, advanced control algorithms for process stability, and modular designs that allow for easy maintenance and upgrades. When a processor selects a plastic extruder manufacturer, they are not just buying a machine; they are entering a partnership. The manufacturer's ability to provide global technical support, process engineering assistance, and a reliable supply of wear parts is as important as the machine's initial performance, as this support is crucial for minimizing downtime and maintaining product quality over the extruder's operational lifespan.