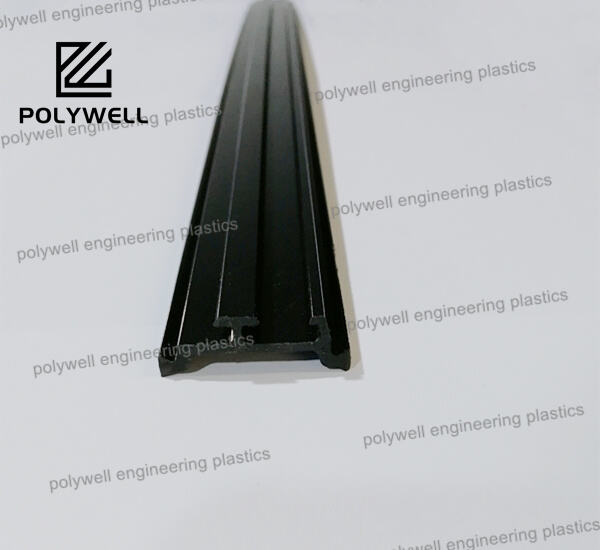

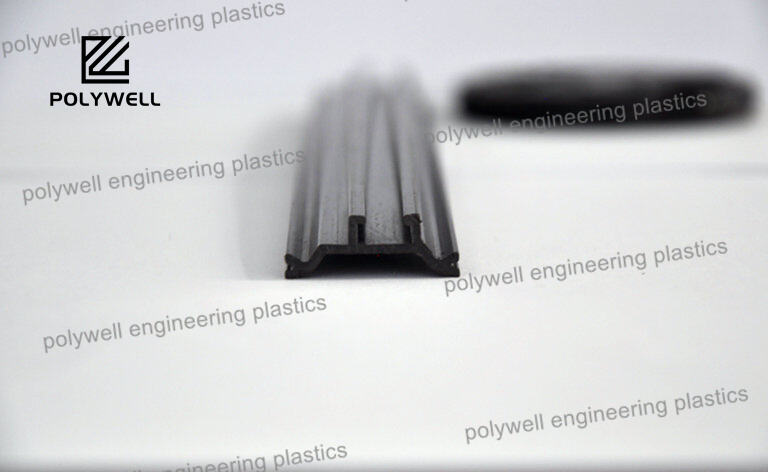

Thermal break insulation specifically denotes the material and design methodology used to create a thermal barrier within an otherwise highly conductive assembly, most notably in metal building components like windows, doors, and structural connections. Its primary function is to drastically reduce thermal bridging, a phenomenon where heat flows easily through the conductive path, leading to energy inefficiency and cold spots. This insulation is not a bulk filling material but a strategically placed, continuous element with low thermal conductivity that physically separates the interior and exterior sections of a metal profile. The most common and effective materials for this purpose are rigid, high-strength polymers, particularly glass-fiber reinforced polyamide (e.g., PA66 GF25/30), which offer an optimal combination of a low k-value (~0.3 W/m·K) and high mechanical strength to withstand shear and compressive forces from the metal cladding and structural loads. The performance of thermal break insulation is quantified by its thermal transmittance (Ψ-value, Psi-value), which measures the linear heat loss at the junction. Effective thermal break insulation must maintain its properties over decades, requiring excellent resistance to creep under sustained load, thermal cycling, UV degradation (if exposed), and moisture absorption. The manufacturing process, typically precision extrusion followed by a pour-and-debridge technique for aluminum windows, is critical to ensuring a void-free, strong bond between the insulation and the metal. This specialized form of insulation is a cornerstone of high-performance building envelopes, directly contributing to reduced energy bills, improved occupant comfort by raising interior surface temperatures, elimination of condensation, and compliance with increasingly stringent international energy codes and sustainability standards for green buildings.