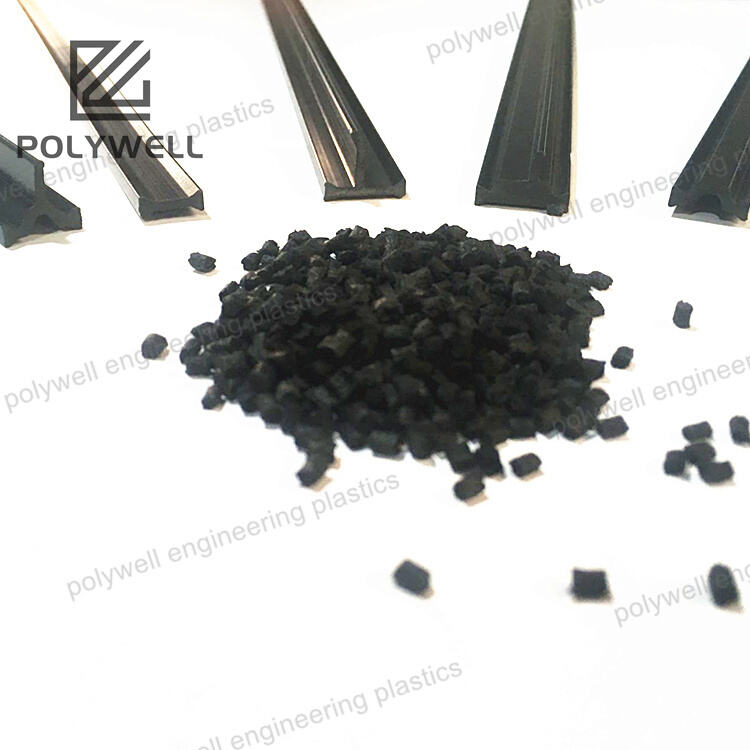

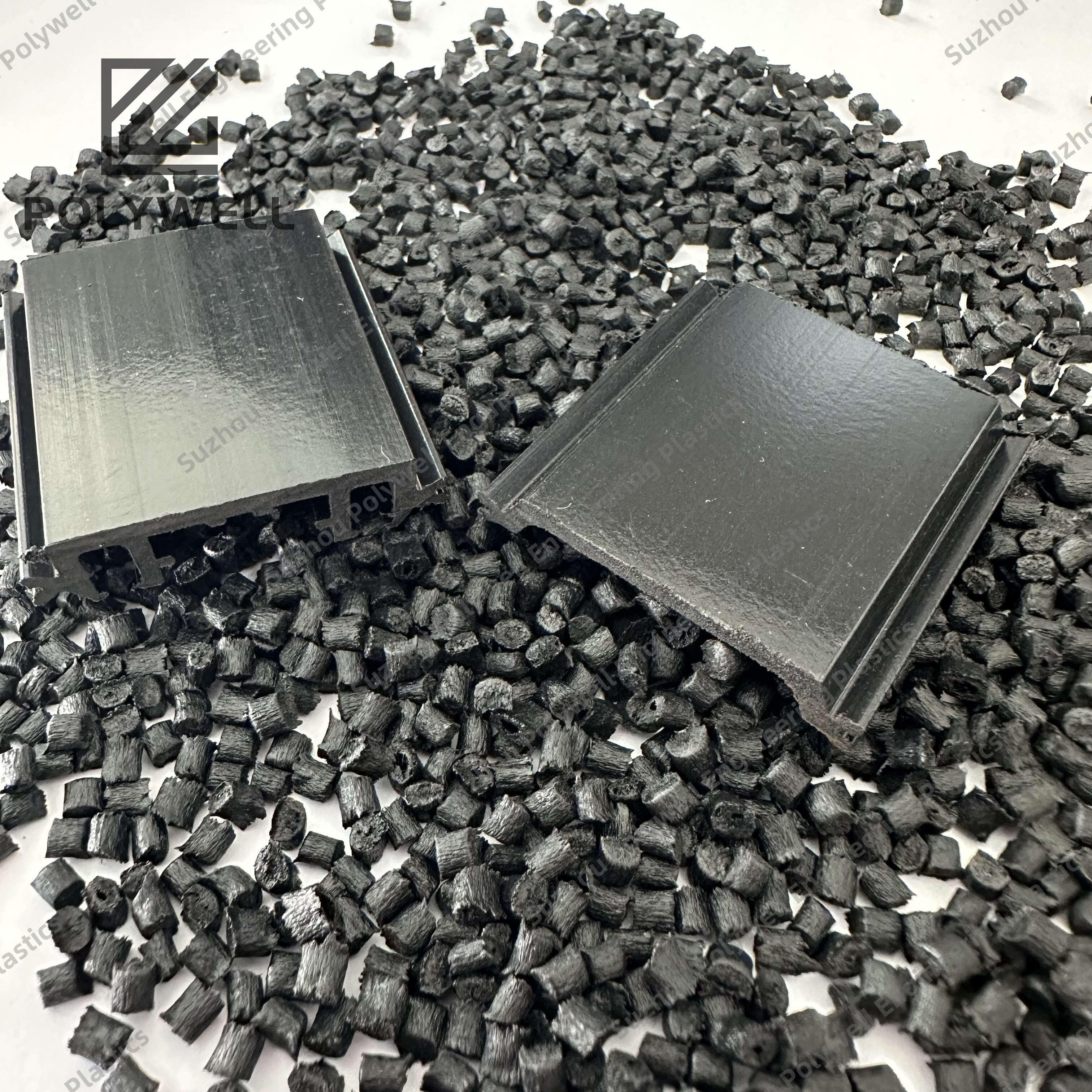

Polyamide plastic, widely known by the trade name Nylon, is a workhorse engineering thermoplastic characterized by a unique combination of strength, durability, and thermal resistance. Its molecular structure, featuring repeating amide linkages, creates strong hydrogen bonds between chains, resulting in high mechanical strength and a relatively high melting point compared to many other plastics. This structure grants it exceptional toughness and the ability to withstand repeated impact and loading. It is famously wear-resistant and has a low coefficient of friction, making it suitable for moving parts like bushings and gears. A critical aspect of its behavior is its relationship with water; as a hygroscopic material, it readily absorbs moisture from the air. This absorbed water acts as a plasticizer, markedly improving the material's toughness and impact resistance while decreasing its stiffness and dimensional stability. Therefore, a "dry as molded" part will be stiff and strong, but brittle, whereas a "conditioned" part will be tougher but less rigid. This moisture sensitivity mandates thorough drying before processing to prevent defects and property loss. Polyamide plastic is easily processed via injection molding and extrusion into a vast array of components, from intricate electrical connectors and fasteners to durable fibers for textiles and ropes. Its blend of properties has secured its position as a fundamental material across countless industries, including automotive, electronics, consumer appliances, and industrial machinery.