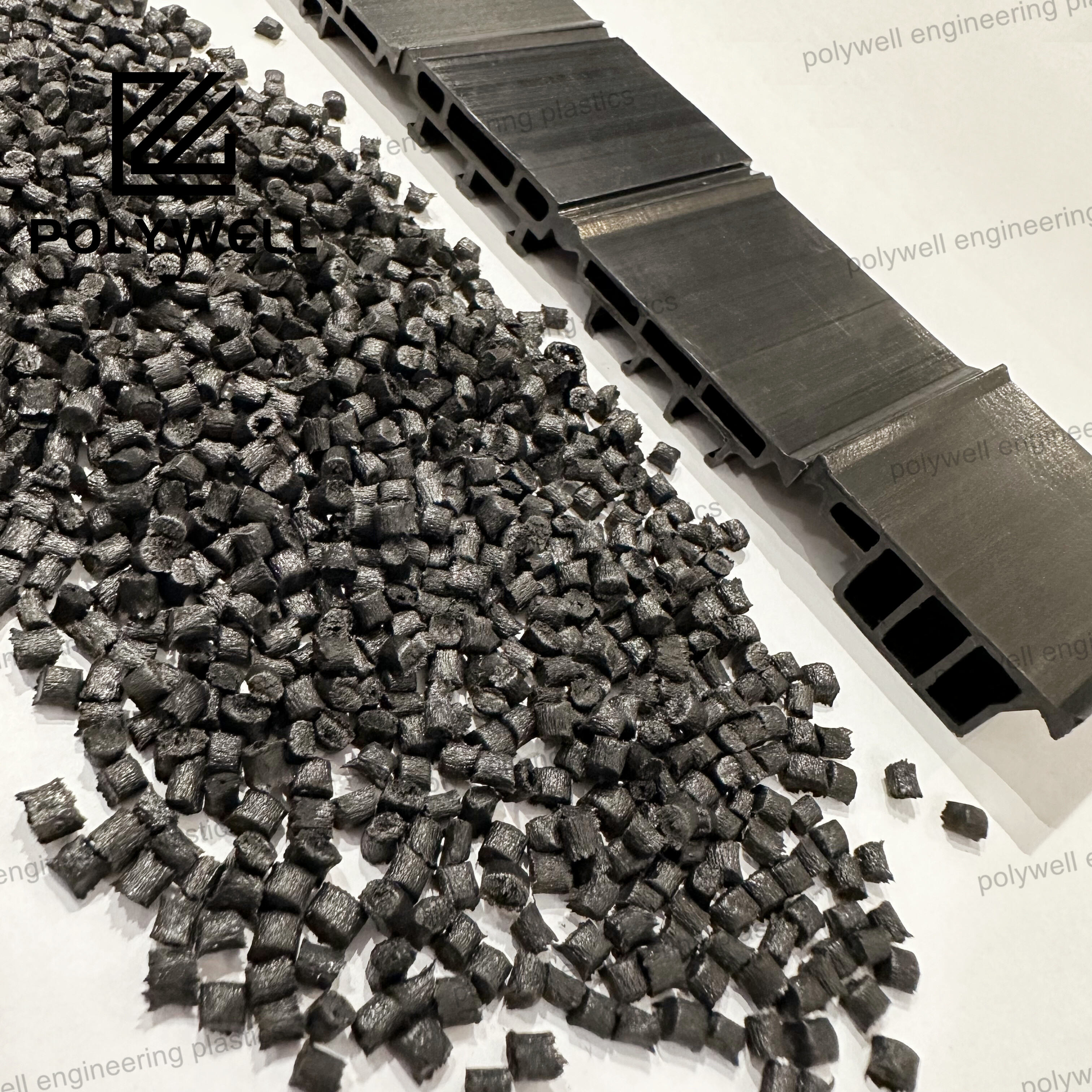

PA66 GF25, or polyamide 66 with 25% glass fiber, is extensively utilized in heat insulation applications due to its low thermal conductivity (typically 0.2–0.3 W/m·K) and ability to maintain structural integrity at elevated temperatures. This material combines the inherent thermal stability of PA66—which has a melting point around 260°C and a continuous use temperature up to 180°C—with the reinforcing effects of glass fibers, resulting in reduced heat transfer and improved dimensional stability under thermal cycling. In insulation contexts, PA66 GF25 is employed in components such as thermal barriers, housings for electrical devices, and automotive under-hood parts, where it minimizes heat flow and protects adjacent materials from excessive temperatures. The glass fibers not only enhance mechanical strength but also reduce the coefficient of thermal expansion, limiting deformation and ensuring long-term performance. Processing via injection molding allows for complex geometries that optimize insulation, with design considerations including wall thickness uniformity and the integration of air gaps to further retard heat conduction. Additionally, the material's resistance to flames, achieved through additives like halogen-free flame retardants, makes it suitable for safety-critical applications in construction and electronics. Environmental factors, such as exposure to moisture or UV radiation, are mitigated through stabilizers, ensuring durability in outdoor settings. Overall, PA66 GF25 offers a versatile solution for heat insulation, blending thermal efficiency with mechanical robustness, and is selected for its ability to meet stringent industry standards while providing cost-effectiveness and ease of manufacturing in diverse global markets.