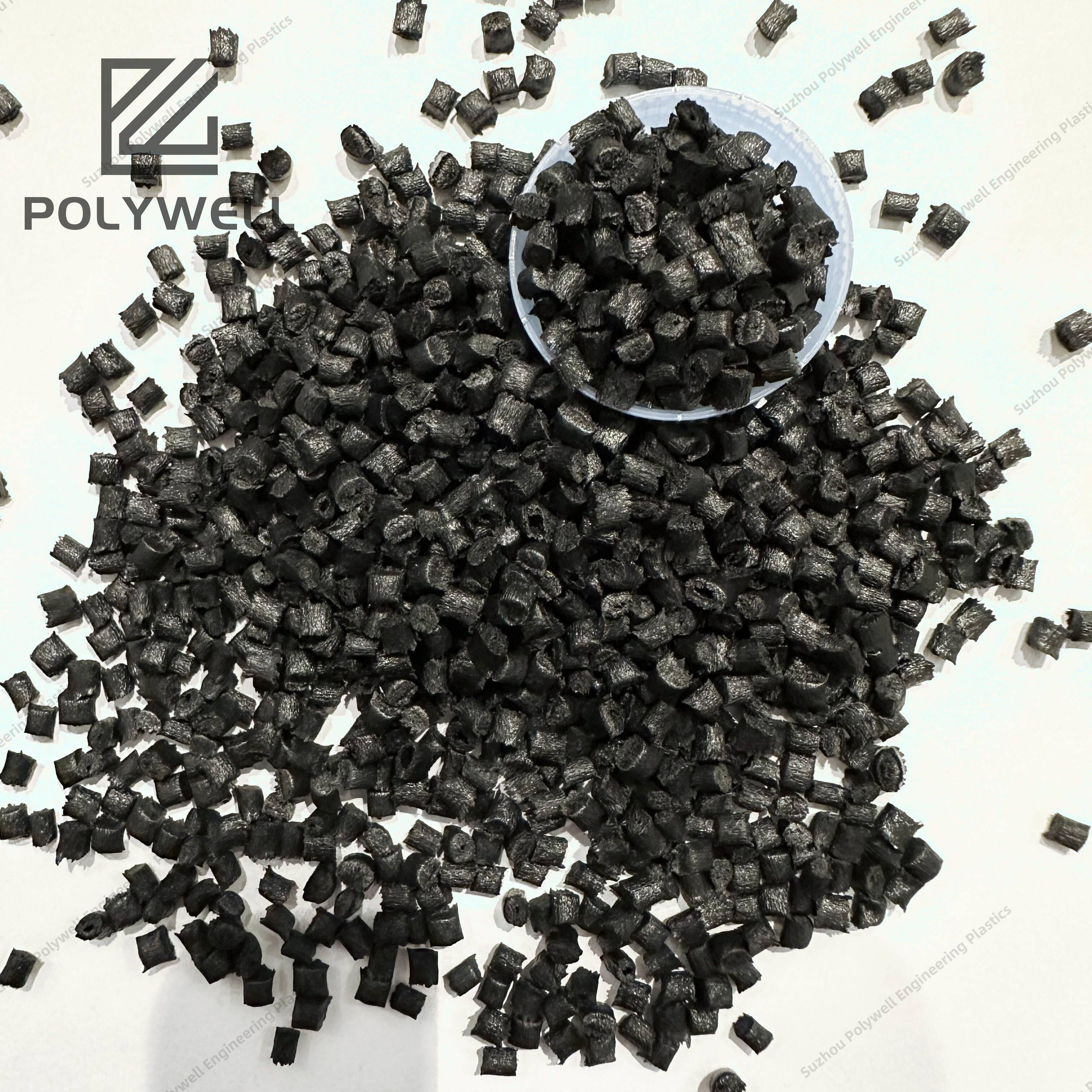

Nylon 66 GF30, or polyamide 66 with 30% glass fiber reinforcement, is an advanced engineering thermoplastic that offers superior mechanical and thermal properties compared to lower fiber-filled variants. The increased glass fiber content elevates tensile strength to approximately 200 MPa, flexural modulus to 12–14 GPa, and impact resistance to around 20 kJ/m², while the heat deflection temperature reaches 250–270°C under load. This makes it ideal for high-stress applications in automotive, aerospace, and industrial equipment, where components must endure extreme temperatures and mechanical loads. The material's granular or pellet form ensures efficient processing in injection molding, with melt temperatures of 265–285°C and mold temperatures of 80–120°C recommended to minimize fiber degradation and achieve uniform dispersion. However, the higher fiber content can increase abrasion on machinery and necessitate robust mold designs with hardened steels. Shrinkage is reduced to 0.1–0.3% in-flow and 0.4–0.6% cross-flow, enhancing dimensional stability for precision parts like gears, brackets, and housings. Electrical properties remain good, though glass fibers may slightly reduce dielectric strength, and resistance to chemicals, oils, and creep is excellent. Environmental factors include recyclability and the need for UV stabilizers in outdoor applications. Overall, nylon 66 GF30 provides a high-performance solution for demanding environments, balancing enhanced stiffness and heat resistance with processability, and is often selected for applications where weight reduction, durability, and compliance with international standards are critical, catering to diverse client needs across cultures.