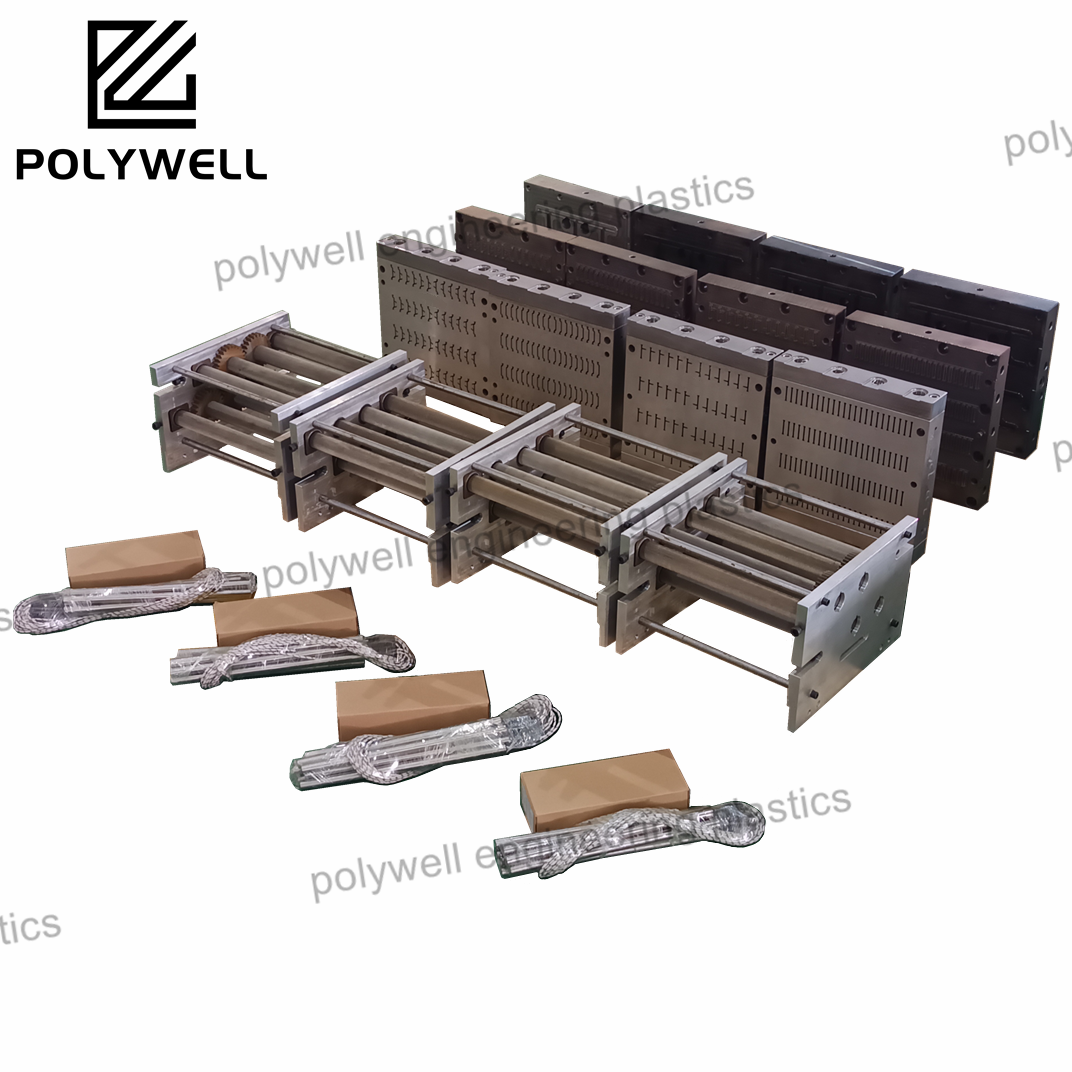

Hollow die extrusion is a specialized manufacturing process used to create plastic or metal profiles that feature one or more internal voids or chambers. The complexity of this technique lies in the design of the die, which must form both the external shape and the internal hollow section simultaneously. In plastic extrusion, this is most commonly achieved using a spider die or a pin die. A spider die uses several "legs" to support a central mandrel within the die body. The molten polymer flows around these legs and re-joins (or "re-knits") in a welding chamber before exiting the die. The quality of this re-knit is critical, as a poor weld line can be a structural weakness. Alternatively, for less viscous materials, a side-fed mandrel die may be used to avoid weld lines altogether. In metal extrusion, a similar principle applies using a porthole or bridge die, where the metal billet is split into streams that flow around a bridge supporting the mandrel and are then welded together under high pressure and temperature in the weld chamber before exiting the die. Hollow die extrusion requires precise control over process parameters like temperature, speed, and pressure to ensure a strong, seamless weld. This method is indispensable for producing a vast range of essential products, from multi-chambered PVC window frames and complex PA66 thermal break strips to aluminum tubes and automotive structural components, where the hollow sections provide significant weight savings and improved structural efficiency.