When designers design the shape of the PA66 thermal break strip, they focus more on the overall heat insulation performance of the window and the matching degree between the PA66 thermal break strip and other accessories.

However, designers are not familiar with the mold and the production process of the PA66 thermal break strip, so sometimes designers do not know whether their designed PA66 thermal break strip can meet the production conditions.

At this time, our company can come into play.

Our company started with researching raw materials and later added many production lines for PA66 thermal break strips.

Years of experience in producing PA66 thermal break strips allow us to quickly find out if there is any defects in the current design, and whether it will bring difficulties for the future mold manufacturing and PA66 thermal break strip production.

This service can help clients avoid risks from the beginning of the project, thereby reducing losses caused by unreasonable design.

Here I have a case for you:

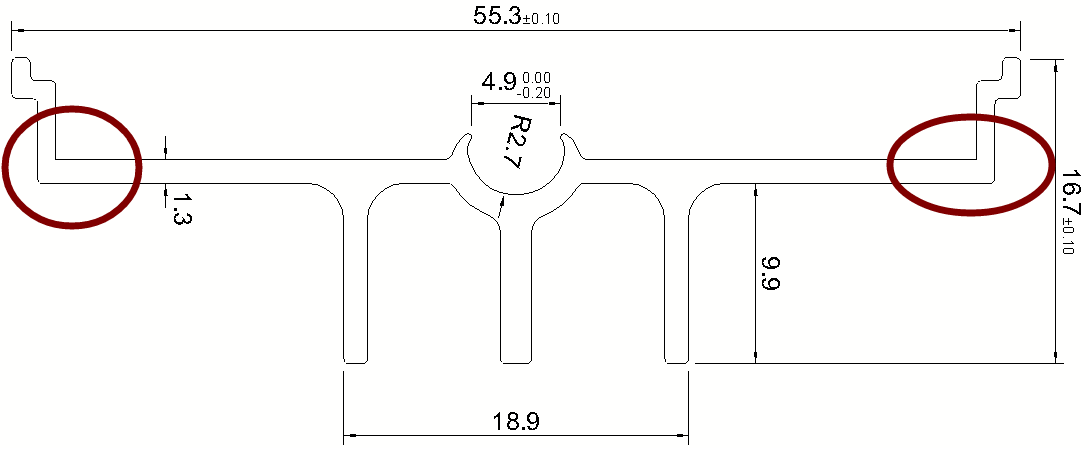

One of our customer sent this newly designed drawing to us and asked for our comments.

We checked the drawing and find below risk:

This shape is asymmetrical, so the finished strips will bend and twist.

If you believe in Polywell, if you have newly designed drawing, if you want to know if your newly designed drawing has any risks during the future production process, please feel free to contact us, we will provide you with our professional analysis. What's important is that this service is free of charge.